US $1500

Directions

Similar products from Other Woodworking Equipment & Tools

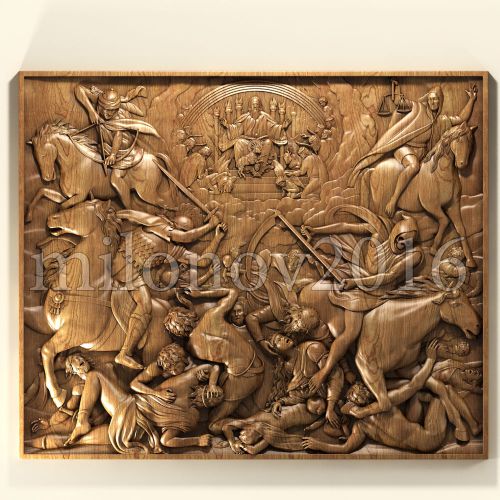

3d stl Model 2 pcs pack for CNC Router Artcam

3d stl Model Relief for CNC Router Artcam Cut3d Aspire

3d stl Model for CNC Router Artcam Cut3d Aspire

Miller Dowel s 2X Joinery Kit - Birch - NEW

3d stl Model Relief for CNC Router Artcam Aspire

120v Electric Wood Working Chisel Carving Machine Tool w/ 5 Carving Blades

ELU 3 Wheel Variable Speed Power Feeder Single Phase 220V Wood Stock Feed

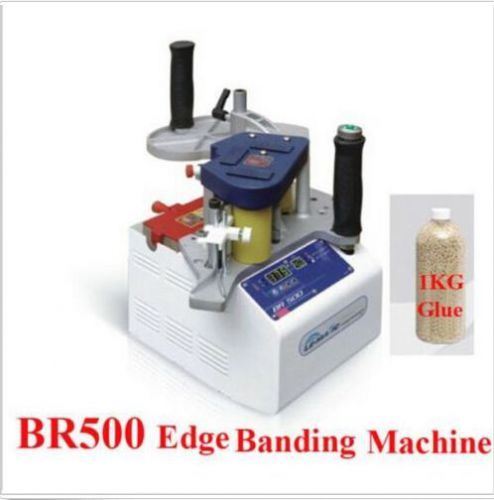

BR500 Le-matic Portable Manual Curve Woodworking Edge Banding Machine Bander BI

New technology for manufacturing interior doors

Sodick cabinet air conditioner cooler

MIllwork/Cabinet Leveling Feet-LOT

3d stl Model Relief Fireplace for CNC Router Artcam Aspire

65mm Spindle Dust Cover Vacuum Cleaner Dustproof Remove For CNC Router Woodwork

Cosma Edruflex Sanding Brushes - Free Shipping

People who viewed this item also vieved

Lot 3183 Crown Moulding Weinig / WKW Corrugated Knives Shaper Moulder

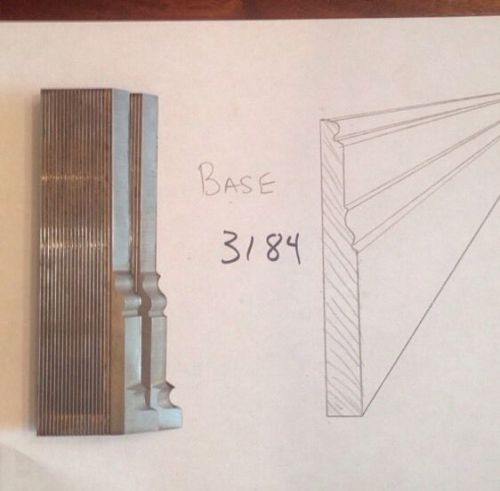

Lot 3184 Base Moulding Weinig / WKW Corrugated Knives Shaper Moulder

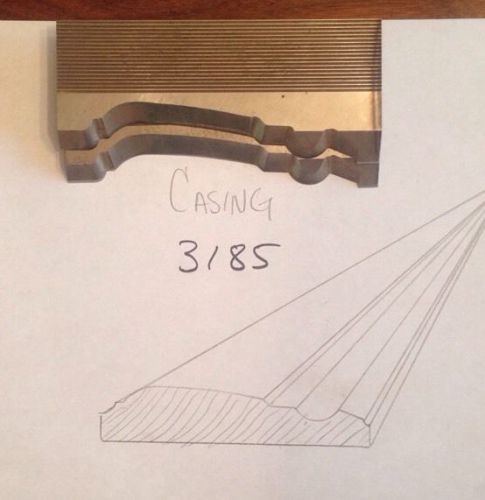

Lot 3185 Casing Moulding Weinig / WKW Corrugated Knives Shaper Moulder

Tool Shop 4 pc. Wood Chisel Set & Sharpening Stone NIP

10 Piece Wooden Chisel Set 140MM Hard Wood Handles case Brand New

New Narex (Made in Czech Republic) Pair 1/2" and 3/4" Dovetail Japanese Chisels

Bessey 3100736 Replacement Morpad Assembly 1200/1800/2400/4800 Series

Irwin Vise Grip 10Cr(#4935576) Curved Jaw Locking Plier

8x70 Left Hand Thru Drill Bit Lot of 10

5x57 Right Hand Dowel Drill Bit Lot of 10

5x57 Left Hand Dowel Drill Bit Lot of 10

Wood Veneer Walnut 9x23 22pcs total Raw Veneer "EXOTIC" WAL7 12-19

Wood Veneer Figured Walnut 8x31 18pcs total Raw Veneer "EXOTIC" WAL6 12-19

Wood Veneer Figured Walnut 9x24 22pcs total Raw Veneer "EXOTIC" WAL5 12-19

Rockwell Delta Crescent 20" Wood Band Saw Op, Maintenance, & Parts Manual *841

Rockwell Crescent 8" Light Jointer Service and Parts List Manual *836

Rockwell Crescent 12" & 16" Jointer Service and Parts List Manual *840

ROCKWELL INTERNATIONAL 43-922 CARBIDE TIP COVE & BEAD SHAPER FIVE CUTTER SET

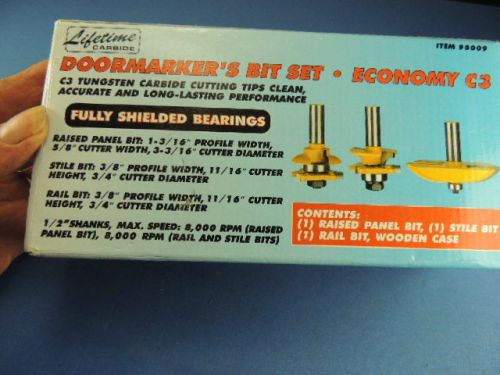

New Lifetime Carbide 3 PC 1/2" Shank DoorMaker's C3 Tungsten Carbide Tip Bit Set

Vermont American 1/4" Titanium router Bit 22310 NIP veining

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies