US $25.50

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | SIMPSON |

| Model | CRACK PAC |

Directions

Similar products from Caulk & Sealants

4 Pack Akfix Siliconized Acrylic Sealant Paintable Caulk 10.5 oz - White

Epoxy Table Top Resin, 2 Gallon Kit, Crystal Clear, Includes Part A & B 135368

KAMPEL SEAMFIL REPAIR FILLER MINWAX WOOD FINISH STAIN MARKER EXTRAS LOT BUNDEL

NEW Red Devil 0636 Blacktop & Roof repair 10.1 Oz. Cartridge

Huntsman Araldite 2021 Toughened 5-min Methacrylate (MMA) Multi-Use Adhesive

graffiti armor Paint it on, Peel it off. NEW

(3 tubes) Manus Bond 76-AM Self-Leveling Sealant / Adhesive

Protecto CMU 100 Sealant Adhesive 1 Gallon 60 Sq feet

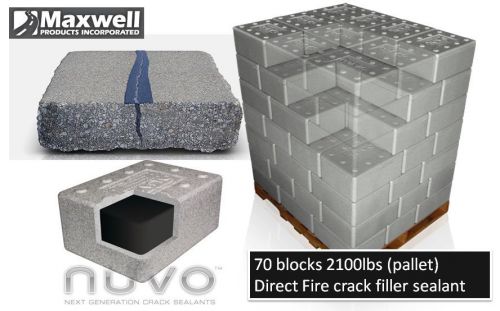

DIRECT FIRE Maxwell Elite Crack Filler Crackfiller Sealant(70 30# blocks PALLET)

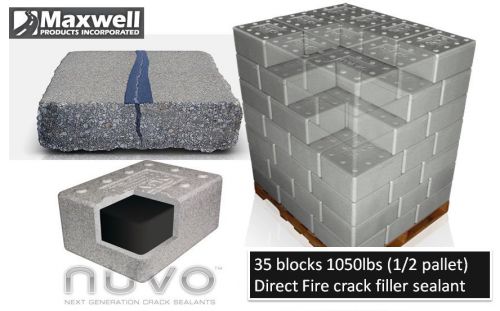

DIRECT FIRE Maxwell Hot Rubberized Crack Filler Sealant (35 blocks HALF PALLET)

2Oz Probond Advanced Mp Adhesive

Hilti Injectable Mortar Rebar Epoxy

Corian Mixpac DM200-01 Manual Adhesive Dispenser, 200ml, New

![W.R. WR Meadows VOCOMP-25 Concrete Curing and Sealing Compound [5 Gallons]](/_content/items/images/73/3193273/001.jpg)

W.R. WR Meadows VOCOMP-25 Concrete Curing and Sealing Compound [5 Gallons]

1Qt 2X Premium Vinyl Crack Filler

Sikabond 10.1oz Constrctn Adhesive

CRL Motsenbocker's Lift Off 4 Remover for Spray Paint Graffiti 22 FL OZ

People who viewed this item also vieved

2 CCI Model 02841 Ground Fault Circuit Interrupter Power Cord 2-1/2' Length GFCI

Arrow Fastener Hammer Tacker-HT55

Hilti Steel Decking Pneu. Gun. R4DW-4 with Extra O-Rings, Tools aand Steel Case

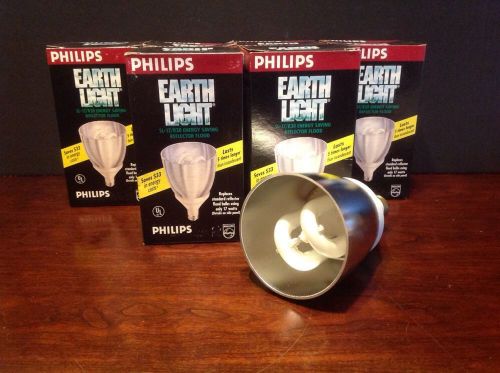

Philips Earth Light SL17 Watt R30 Reflector Flood Light Bulb Lot Of 6 Soft White

LED 660 Retrofit, for 250 watt Metal Halide, E39 MOGUL, 5500k, LIGHT BULB

18X18 BARK CARPET TILE CP44N3116PKQ

L&G's Victorian Gingerbread Texas Lone Star Fretwork Corner Trim Brackets 10"

POST B - H Reed Half Post 3-1/2 x 35-1/4 (Alder Shown)

Hart&Cooley 18x12 White Heater Vent Cover Register Furnace Heating Grill Grate

3-Pack 8" X 4" 3-Way Registers White Sidewall Or Ceiling Applications 0609

Stone Master 4" Wet Premium Polishing Pads - Vic International

FW05068 INSECT SCREEN WHITE RETRACTABLE PART#2530036

FW03168L INSECT SCREEN WHITE RETRACTABLE PART# 2530018

Frost King Window Insulation Kit 42"x62" 1 Sheet

Spray Foam Insulation Kit, DOW Froth Pak 200 Sealant, 200 board feet

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies