US $5,009.53

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Make | Eaton |

Directions

Similar products from Air Compressors

SULLAIR AIR COMPRESSOR 10-30 AC/AC ELECTRIC

Champion 10 HP Electric compressor

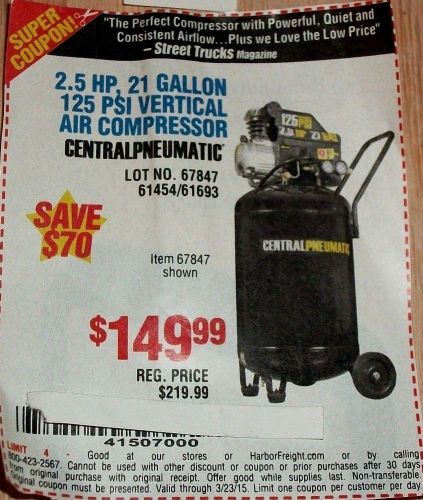

2.5 HP, 21 gallon 125 PSI vertical air compressor "COUPON ONLY"

Never Used John Bunn Model BA400A Silent Air Compressor

3.5 Gallon 135 Psi Pancake Compressor

20-Horse power Champion air compressor,Four cylinder, Two stage, 120-Gallon

NEW Falcon GAC 250 Air Compressor - Gasoline Powered

Ingersoll Rand Industrial Air Compressor 15TE 20 Horsepower

Ingersoll - Rand / RPM 2100 / Size 728LA2 / Used

Industrial! Eaton Compressor 29CFM Refrigerated Air Dryer

COUPON $70 OFF VERTICAL AIR COMPRESSOR 2.5 HP 21 GALLON 125 PSI HARBOR FREIGHT

Bonaire Inflation Machine Cordless Multi-Purpose Inflator NIB

Vintage-Champion-V-Twin-Air Compressor Pump with Extras-No Reserve

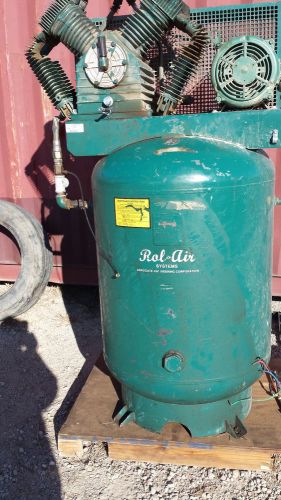

ROL-AIR 10 HP ELECTRIC AIR COMPRESSOR V1031260K

30 HP Rotary Air Compressor with 120 Gallon Tank ES-8 30H 208V

32498024 Shaft Seal Kit OEM Ingersoll Rand

42361790 Lip Seal Kit OEM Genuine Ingersoll Rand Part

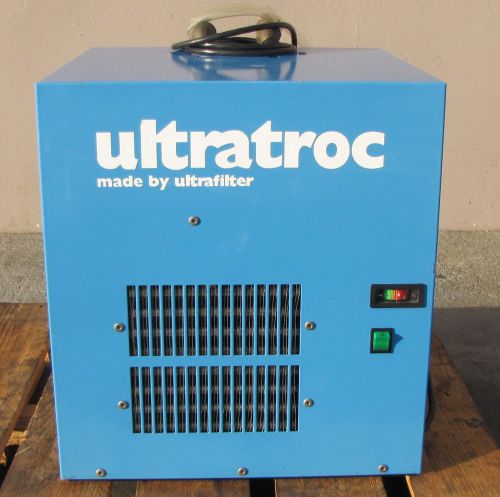

Ultrafilter Ultratroc Refrigerated Air Dryer for Compressor 30 CFM 115V

NEW US AIR ROTARY SCREW COMPRESSOR GHH Ingersoll Rand air end Pump 15 HP 15HP

People who viewed this item also vieved

4 Premium 5x5 Scaffolding Sets w/10ft Brace #6 1.625 in. OD

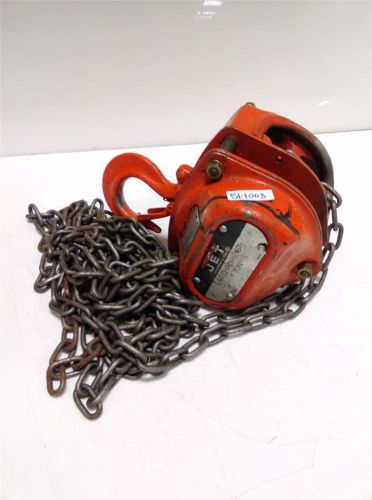

JET EQUIPMENT & TOOLS 1 TON CHAIN HOIST L-90

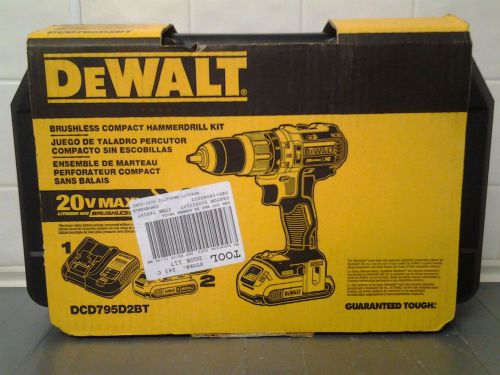

DeWalt 20V MAX XR Li-ion Brushless Compact Hammerdrill Kit (DCD795D2BT) *NEW*

DEWALT New 20V 20 Volt Max XR 2000mAH Li-Ion Slim Battery For Power Tool

SCREW DRIVER DELTA REGIS ESL324-ESD

Onan Generator. 3 Ph, 12.5 KW Gas

DSE Deep Sea Electronics DSE9461 24 Volt 10 Amp Battery Charger LCD 24V 10A #11

Pre-owned & Tested #S1M-180 6" Angle Grinder Brand Unknowned (No Disc)

Ramset Model MD380 Red Head With Case Used Working Great

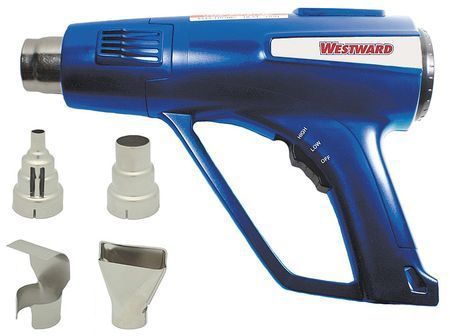

WESTWARD 4HWK5 LCD Heat Gun Kit, 130 to 930 F, 5/10 Amps

TEKTON Three-Size Tubing Bender 6519 - Used

WACKER OEM 5200007070 RT UNIT DRUM SCRAPER BAR KIT WIDE NEW UNOPENED

STANLEY VIDMAR GREY 11 DRAWER TOOL/PARTS CABINET 30"L X 28"W X 59" H

Cold Tire Patches 32mm 42mm 55mm 75mm Rubber Car Bicycle Bike Puncture Patch

Grout and Thinset Mixing Dril 1200-W with 2 Speed Gearbox and Progressive Switch

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies