US $110

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Manufacturer | Hypo |

| Brand | Hypo | ||

| Country/Region of Manufacture | China | ||

| Model | SNR0016m16 95 Degree |

Directions

Similar products from Drilling Heads & Tool Holders

TMX 3/4" INDEXABLE BORING BAR WITH PALBIT TCMT CARBIDE INSERTS

ULTRA-DEX 3/4" CARBIDE BORING BAR WITH CPMT KENNAMET CARBIDE INSERTS

Iscar ITS-Bore Boring Head Tool Holder BHFI MB50-50-60 ETM HSK-A 100-MB50

WOHLHAUPTER UPA3 SET FACING HEAD MOORE JIG BORE SHANK, VERY GOOD CONDITION

E08-STFPL2 KENNAMETAL Boring Bar & TPMT 21.51SQ UE6110 (8) New*

VALENITE E-Z SET adjustable boring head Vintage Tool Found Old Machine Shop Used

A08M SCLCR 2 SANDVIK Coolant Boring Bar

Criterion Model No. 3 Boring Head Tool Bar - R - 8 For Bridgeport

10Pc MGMN200 Insert +MGEHR 16x100mm +MGIVR 20x200L Grooving Turning Toolholder

3Pcs/Set Of 7 10 12mm SCLC Internal Turning Toolholder Bore Boring Bar For CCMT

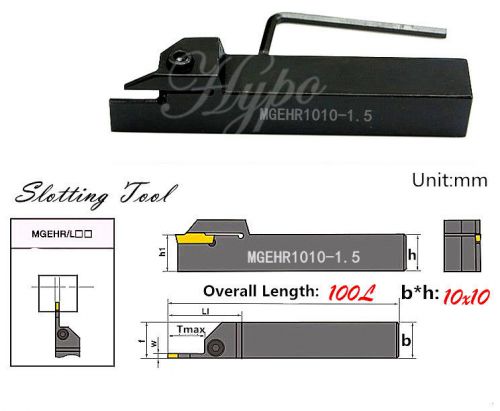

MGEHR1010-1.5 10x100L Lathe External Grooving Toolholder For 1.5mm Width MGMN150

NEW #4 MORSE TAPER BORING BAR 100581-2 WITH 11/16 PILOT , FREE SHIPPING!!!

KURODA #UFB-3 AUTOMATIC BORING & FACING HEAD BRIDGEPORT R8 WOHLHAUPTER JAPAN

Boring Head Rough Cut With R8 Shank

Seco Indexable Boring Bar 43198

5/16" KENNAMETAL E05SCLPR18 CARBIDE BORING BAR 5" LONG COOLANT THRU

5/16" KENNAMETAL E05H-STLDR1.28 267398 CARBIDE BORING BAR 4" LONG COOLANT THRU

Komet Micro Adjust Boring Head ABS 50 TC-4527-A

Indexable Boring Bar, Carbide Insert, .5" Shank

People who viewed this item also vieved

Procunier #2 Tap Collet for #10 Size Taps

Procunier #2 Tap Collet for 5/16" Size Taps

Two, BT 30 LYNDEX 1" End Mill Holder Marked B3006-1000, BT30

NEW BUNTING BEARING CB162412 BRONZE 1X1-1/2X1-1/21IN BUSHING D336294

LOT 3 NEW DODGE ASSORTED 117098 2517X2-3/8 P1 1-1/8 SK2-3/8 BUSHING D396011

CAT 50 Retention Knob, 50RK-138-45C coolant thru, Fitz rite

Akko SEL 25x25 M16 External Indexable Threading Tool Holder

Akko S12K SD-CR/L 07 for DCMT 07

ISCAR MSBNR 20-6E Self Grip Tool Holder Carbide Inserts USED

KENNAMETAL DFCNR-164C INS54-43 Tool Holder USED

Vintage Machinist 1/2 inch Drill Chuck with 1/4 inch shaft

Jacobs 1/2" Drill Chuck with (10) Assorted Center Drills, from 9" South Bend

Quick Change ER32 Collet Chuck, Kennametal KM32ER3251

Smith Tool 221-TR20-S0026 Size1 Tap Holder 924260303

Nichols Vertical Milling Head Attachment rare drive collet and 4ns collects

Giri Series N AL 1 DA 30000 A60000 High Speed Spindle

Sunnen JN 95 Junior Cylinder Hone-One Stone Sets

BIG LOT OF NEW & USED ASSORTED SUNNEN HONE MANDRELS & WEDGES

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies