US $890

Directions

Similar products from Heat Pressure Equipment

15x15 Heat Press Machine Dark/Light Inkjet T-shirt Transfer Paper Christmas Sale

Christmas Sale! 3D Sublimation Heating Press Machine Latte Mug CISS Ink Transfer

100Sheets A4 Sublimation Transfer Paper Heat Press Sublimation Mugs Plates Press

5in1 Heat Press Machine Digital Transfer Sublimation T-Shirt Mug Hat Plate 1250W

Mug Press Machine Sublimation Mugs Heat Transfer Paper CISS KIT Christmas Gift

Christmas Promotion 20"x10ft T-shirt Heat Transfer Vinyl Cutting Plotter Press

Geo Knight K16 Heat Press With Digital Controls & Custom Attachment

16"x20" Clamshell Sublimation Heat Transfer Press Machine T-Shirt

3D Sublimation case for iPhone 5.5 s Glossy/Mate White polymer 10-lot

Heat Press 16x24" Digital Clamshell Transfer T-Shirt industrial Machine

50 Dye Sublimation Holiday Christmas Xmas trees 2 sided Heat transfer

36 Sublimation Mugs White 11oz Coated Cup Blank Heat Press Printing Transfer Box

*Seal Compress 101 Dry Mount Laminating Press for Prints Works great

5 in 1 Heat Press Transfer Machine Transfer T-Shirt Cup Plate Cap Bag/DIY Gift

Insta Heat Seal Machine Model #220 Watts 1750

Digital Geo Knight Heat Transfer Press X20/X16

Hix HT-400 15x15 T-shirt heat press - GREAT DEAL. WORKS like a charm

15"X15" HEAT TRANSFER PRESS MACHINE, T-SHIRT, similar to Hix Stahl - CHEAP !!!!

15"X15" HEAT TRANSFER PRESS MACHINE, T-SHIRT, similar to Hix Stahl - CHEAP DEAL

People who viewed this item also vieved

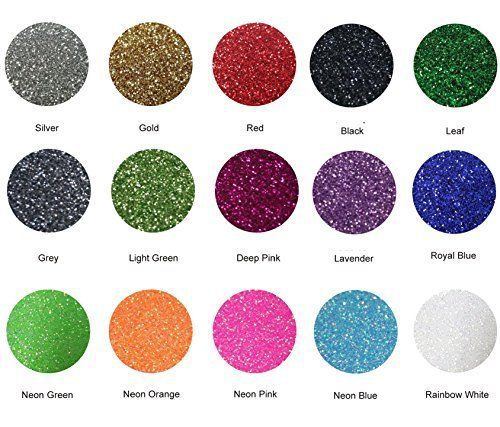

Fame Crafts Glitter Heat Transfer Vinyl (HTV), 12" x 10" 15-Color Starter BUNDLE

Sublimation Silicone Mug Wrap, 12OZ Conical Mugs Cup Clamps --5pcs

3D Sublimation Silicone Mug Clamp, Silicone Mug Mold Mug Wrap for 750ML Bottle

Dingword PURPLE, 20"x 1 FOOT ,T-shirt heat transfer Vinyl / film,IRON ON Heat

New 15x15 Heat Press Machine Transfer Sublimation Printer Tshirts Plates Tiles

New 15" X 15" Clamshell Heat Press Machine, Sublimation / Heat Transfer TShirts

Digifab Dyesublimiation Roll to Roll heat press

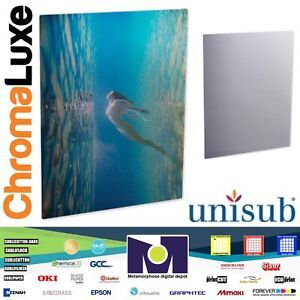

ChromaLuxe Gloss Clear Metal Print 30”x40" .045" thick - 10 per Case 4282

6"x10.5" ALUMINUM SUBLIMATION BLANKS - 1/2" ROUNDED CORNERS - SET OF 10

DynaSub Hair Barrettes and Backs Sublimation Blank Aluminum Various Sizes Shapes

20 SUBLIMATION BLANKS oval BAG TAGS football shaped - both sides

11 OZ ORCA Coating White Ceramic Mug Grade AAA for Sublimation Printing

Sublimation Ceramic Mugs 15oz Grade A White Blanks, Box of 12, From Coastal

Nagatoya Color Paper Na-3435 A4 50 extra thick mouths black A4

PPD Inkjet PREMIUM Iron-On Dark T Shirt Transfers Paper LTR 8.5x11" pack of 8

Sublimation Paper 100 Sheets 8.5 x 11 Inches for Any Inkjet Printer for T-shirts

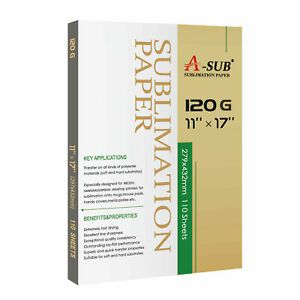

A-SUB Dye Sublimation Heat Transfer Paper 110 Sheets 125g 11x17 Cotton Poly Mugs

Hayes Paper, Waterslide Decal Paper INKJET CLEAR 20 Sheets Premium Water-Slid...

Inkjet Printable Iron-On Heat Tshirt Transfer Paper 11x17 () 50 Dark Fabrics

3279 Printable Heat Fabric Transfer Paper for DIY Projects on Dark Fabr

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies