US $85,350.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Haco |

| Model | SRM 165-12-10 |

Directions

Similar products from Tools for Fabrication Equipment

SWAG 20 Ton Press Brake DIY Builder Kit

Heavy Duty 20 TON Press Brake DIY Builder Kit

Saber 6-12-6 BOX AND PAN BRAKE

PEXTO Roto Table POWER BEAD ROLLER/ FORMING MACHINE/ SHRINKER/ SHEETMETAL HVAC

Used Milwaukee 6855 Heavy Duty 18 GA Sheet Metal Shear - Works Great

0.059Ga Thickness 6" Leg Diacro 2 NEW NOTCHER, Made In USA

16Ga Thickness 12" W Diacro 12 FOOT/HAND SHEAR, MADE IN USA

1.25" Dia Diacro #6 NEW PIPE BENDERS, MADE IN USA - Hydraulically Operated Bende

0.375" Dia Diacro #1 NEW PIPE BENDERS, MADE IN USA

1000Lb Cap. 13" W Littell 10 UNCOILER

8" W 0.062" Cap. Littell 308-5PDL STRAIGHTENER

135 Ton 144" Bed Haco PPES 135-12-10 NEW PRESS BRAKE, REBUILT CNC PRESS BRAKE

200 Ton 168" Bed Haco Synchromaster SRM 200-14-12 NEW PRESS BRAKE, Standard ATS

25 Ton 12" Strk Pressmaster HFP-25 H-FRAME HYDRAULIC PRESS, Built-In Speed Contr

165 Ton 120" Bed Haco Synchromaster SRM 165-10-8 NEW PRESS BRAKE, Standard ATS 5

165 Ton 96" Bed Haco Synchromaster SRM 165-8-6 NEW PRESS BRAKE, Standard ATS 560

150 Ton 96" Bed Haco Synchromaster SRM 150-8-6 NEW PRESS BRAKE, Standard ATS 560

People who viewed this item also vieved

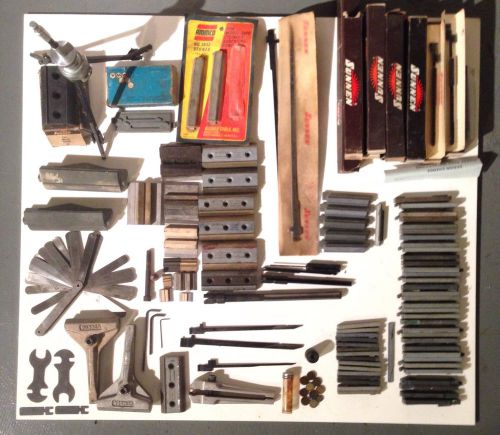

MACHINIST LATHE MILL TOOLS NIELSEN TRANSFER SCREWS 2 PARTIAL SETS

LOT of (50) OK TOOL LATHE PIECES...for SHAPER PLANER

Adjustable hand reamers + KNURLING TOOL & Rex 95 Lathe Tools

VALENITE Econo Mizer Loc-A-Dex 2" Milling Cutter MRN SS-134-5R3-075S

NEW interstate t slot cutter 1 1-1/4" hss end mill side cut 03000643 MAKE OFFER

LOT Slitting saw arbors and FLY Cutters machinist toolmakers mill tools id.12

Drill Press Clausing 15? V.Speed Floor Model Drill Press Xtra Nice Built 1995+/-

Minster 30 Ton Pulsar Stamping Press 23346

3M 6" Stikit Paper NH Disc 735U P220 Grit. PSA--Ceramic Aluminum Oxide. Box 50.

Vintage Sears, Roebuck and Company Grinding Wheel Dresser w Box, Instructions

USED SPG TDR-SDR 80 Tool Drill Sharpener w/ Extras

NIB Lot of 3 Helicoil Therad Insert Taps 2087-12 M12x1.75 DEAL!!!!

Hornady Lock N Load Die Bushing 9 Pack 44096 (SKU103)

Stainless Re-Nu Thread Repair Insert Kit - Metric - Northwestern 30202 - US Made

#JWTS-10 JET 10" Tilting Arbor Table Saw (New 1990)

Johnson - Dake Model J Saw Guide Arm Link & Holder Assembly

Drive Belt for Marvel Bandsaw 8-1186 Jason 9 169 500L

Wuko #1006 Roof Seaming Machine

CYLINDER ENGINE HONE KIT 2.1/2 INCH to 5.1/2 INCH HONING MACHINE + HONING STONES

LARGE lot of Sunnen honing Mandrels, Stones, Shoes, Cylinder hone, tools & more!

CJ Winter Bump Roll 3/4-16 x .500

2014 Star SB-20R E Type screw machine with LNS 12 Foot Barfeeder

CJ Winter Bump Roll 1/4-28 x .250

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies