US $73,000.00

| “6 months old - very limited use” |

| Brand | Haco |

| Model | SRM 165-12-10 |

Directions

Similar products from Tools for Fabrication Equipment

Pexto No 576 small burring rotory sheet metal machine 1867 pat. Cool tool

Rowe Reel-Type Powered Uncoiler - Used - AM11331

1/4" x 10' Amada Model M-3060 Mechanical Shear

CNC Strippit FC-750 Turret Punch Press

VINTAGE STEEL STAMPS 1/8" LETTERS A TO Z w/ "&" and "." SYMBOLS - Dovetail Box

DI-ACRO FINGER BRAKE NO.24 S#FB212

SUNEX Model 5250, Manual, 50 Ton H-Frame Press

GEKA 100 ton Ironworker Punch Shear Hydrocrop 100SD Lots of Tooling Included!

NUGIER 200 TON H FRAME PRESS 50" BETWEEN UPRIGHTS, AIR OPERATED

WYSONG MECHANICAL POWER SQUARING SHEAR 1052 52" 10 ga (28848)

ROUSSELLE #2 15 Ton OBI Punch Press 2" Stroke, Air Assisted Clutch

Greenerd #3A Arbor Press 3 tons w/ stand

NIAGARA 189 CRIMPER BEADER ROLLER PEXTO BASE TINNSMITH SHEETMETAL FABRICATION

Manual Metal Pipe Bend Multipurpose Bending 180 Degrees w/ 6 Round 2 Square Dies

Dallas Coil Cradle & Straightener SN 16858

PEXTO Model 383 SLIP ROLL 2' x 20 ga

Pexto 925 Blow horn Stake (Peck Stow & Wilcox Co. Southington, Conn.)

People who viewed this item also vieved

H & G 102 DH CARRIER SET 1-1/32"-1-1/4" LEFT HAND

H & G 103 DH SERIES CHASER BLOCKS 1-1/32"-1-1/4" LEFT

H & G 103 DH SERIES CHASER BLOCKS 1-1/32"-1-1/4"

63" Arm 17" Column Victor 1763H RADIAL DRILL, Spdl Strk 14-9/16", 12 speeds, 7.5

5HP Spdl Victor KY-27VS DRILL PRESS, 6-3/8" Dia., 7.5" Spdl Strk, Vari. Spd

0.25" Dia. Cap Snow TA-1-A TAPPING MACHINE

Mitsubishi .0205 Diamond Guide Head Only

Mitsubishi .0205 Diamond Guide

EDC30UK Drill EDM Chuck with KEY 0.3 - 3.0mm

MADISON INDUSTRIES MICROLLER 6452 SERIES OUTSIDE BURNISHING TOOL, 6452-101-31088

SUNNEN Honing Stone P28NM85 |IY3|

NEW! SUNNEN HONING MANDREL HONING STONES K20 J57

10" Swg 20" cc Landis 1R OD GRINDER, Hyd. Tbl, I.D. Attach.

12" W 24" L Jones & Shipman 1430 SURFACE GRINDER, AUTO IDF, 3X AUTO FEEDS, EMC,

14" Swg 30" cc Brown & Sharpe 2 OD GRINDER, ID att., hyd. Tbl, auto infeed, AUTO

South Bend Gear for 9” and 10K Lathe Quick Change Gearbox #PT628NK1

South Bend Gear for 9” and 10K Lathe Quick Change Gearbox #AS605NK1

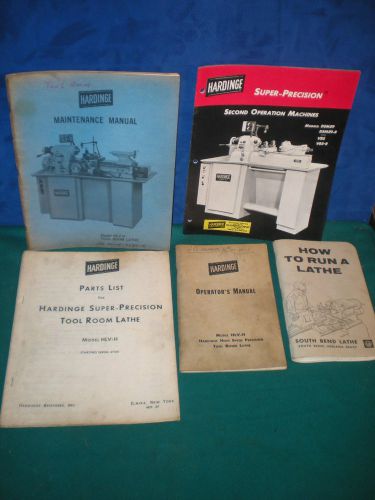

HARDINGE HLV-H Lathe PARTS LIST, MAINTENANCE MANUAL, OPERATER OWNER MANUAL Lot

Milltronics Partner 6 CNC Vertical Machining Center with Centurion 5 Controller

Kearney & Trecker TRI D Milling Machine HEAD K&T

MOON - SIDE MILLING CUTTER- 4 x .261 x 1, USA

Barnes International 7-76-22 Hone Bar Ring

CDI TORQUE PRODUCTS, TORQUE WRENCH, 6004MFRMH, 3/4 DR, 100-600 FT.LB, NEW

CDI TORQUE PRODUCTS, TORQUE WRENCH, 1503MFRMH-QR, 1/2 DR, 20-150 FT.LB, NEW

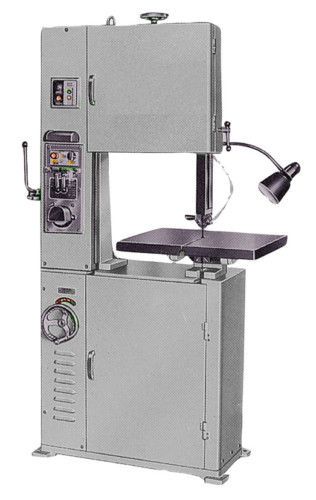

Vertical Bandsaw - Model BAV-450

Eisele,12" Cold Saw 440v VMSIIIPV

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies