US $10.95

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

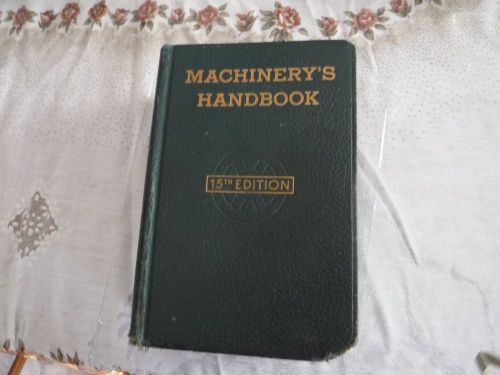

| Seller Notes | “New reproduction.” |

Directions

Similar products from Instruction Manuals for Metal Cutting

MAZAK DD354002004 SQT-15/18 M/MS T32A 7M Elementary Electrical Circuit Diagram

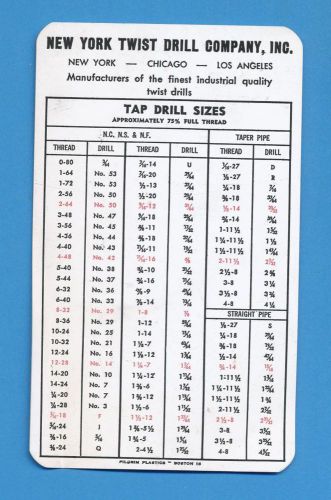

New York Twist Drill Co, Tap Drill Sizes & Decimal Equivalents - VINTAGE

Arter Operators Manual - Model A Rotary Surface Grinder (Inv.18024)

Powermatic Model 66 10 Inch Table Saw Manual

SCRIPTA SR 3D ENGRAVING & DIE SINKING MACHINE MANUAL

MILLRITE MILLING MACHINE POWERMATIC - SERVICE MANUAL PDF

Thermal Dynamics PakMaster 38 XL Plasma Cutter t Instruction Manual *1011

Cincinnati Milling Machine Nos. 2ML, 2MI, & 3MI Service Manual Parts List *384

Thermal Dynamics CutMaster 101 Plasma Cutter Operating Manual *990

KETT KD-400 18 GA POWER SHEARS NEW IN BOX/UNUSED

Logan 8'' metal shaper felt ram dovetail wipers

Thermal Dynamics CutMaster 50 Plasma Cutting Power Supply Service Manual *944

LeBLOND Regal 13"-24" Lathe Manual Running A Regal

1921 Whitcomb Blaisdell Machine Tool Catalog - reprint

WW2 Aircraft Sheet Metal Forming--Draw Bench, Power Rolls & Spinning

Early AUTO Industry MASS Production-- American Machinist Memories 1913-15

The INVOLUTE Gear explained by FELLOWS Gear Shaper - 1936 - reprint

The INTERNAL Gear explained by FELLOWS Gear Shaper Co. - 1936 - reprint

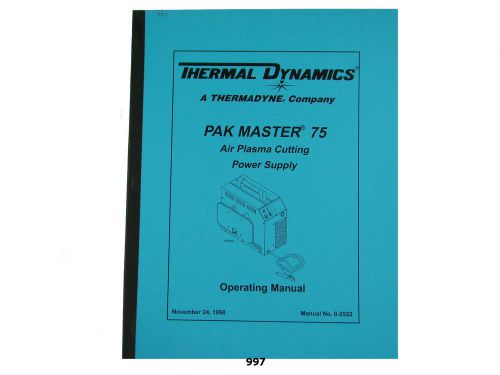

Thermal Dynamics Pakmaster 75 Plasma Cutter Operating Manual *997

South Bend Lathes Parts List 9 inch and 10 K (Inv.18025)

People who viewed this item also vieved

Machinery's Handbook - 20th Edition

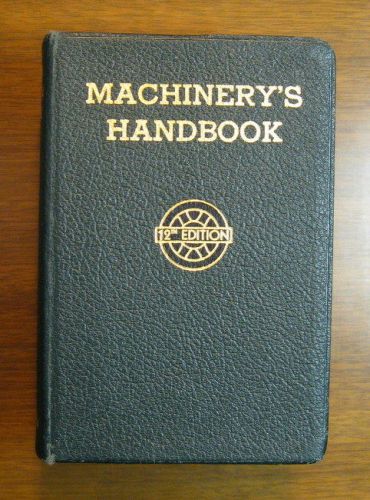

1944 Machinery's Handbook for Machine Shop Drafting by Oberg and Jones 12th Ed

VINTAGE MACHINERY'S HANDBOOK 9th. EDITION 1937

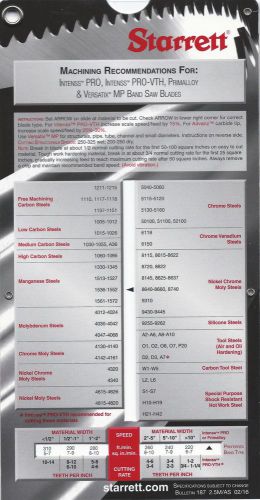

STARRETT Band Saw Slide chart NEW + 2 NEW FREE Starrett pocket charts *

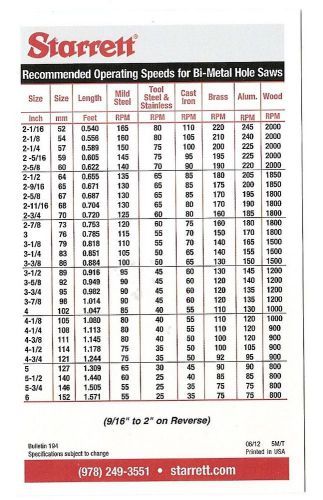

STARRETT 3 DIFFERENT Pck CHARTS TAP & DRILL,METRIC and HOLE SAW SPDS #9

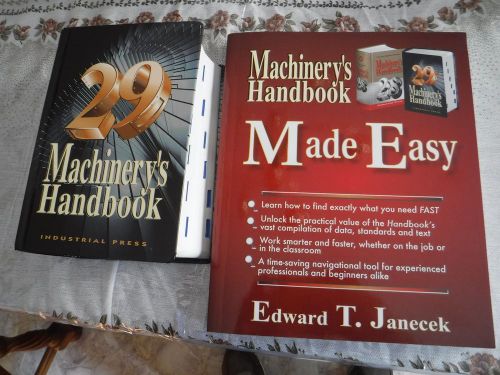

Machinery's Handbook Toolbox edition 29th edition , Machinery's handbook Made E

Machinery's Handbook Toolbox edition 15th edition , toolbox thumb index edition

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies