US $14.99

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Soiling, wear and fading to cover. Names penned on both sides of first blank page” |

Directions

Similar products from Other Instruction Manuals

3461488 Cincinnati Milacron Maxim ballscrew

METAL WORK TECHNOLOGY AND PRACTICE HARDCOVER 1962 BY LUDWIGAND HARDCOVER BOOK

Cinncinati Milacron T3-786 Industrial Robot Parts Manual

Vintage 1962 1963 Destaco laminated calendar Detroit Stamping Company

YAM Yang Iron Works HSMC 650 Parts Manual

Matsuura MC-660V Fanuc 3000C Electrical Drawings

REDIN GEAR DEBURRING MACHINES MANUALS SCHEMATICS SET UP BULLETINS #1581

Sears Craftsman 1 HP GRINDER Owners Operation Manual

Machinist Practical Guide for Cutters Dies Reamers Drill bits end mills

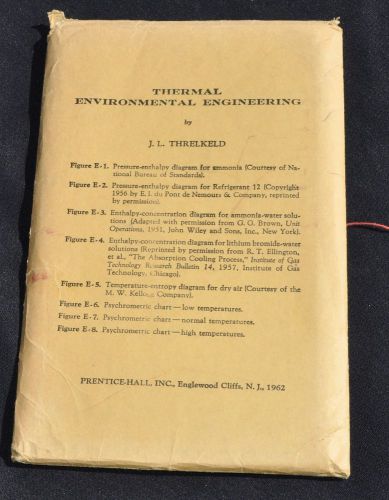

Thermal Environmental Engineering Charts/Diagrams - Oversize sheets

Exacto Turret Milling Machine Manual

1952 Vtg Handbook TAPS and DIES for Screw Threads- Metal Cutting Tool Institute

Mazak H-22 Horizontal CNC mill Complete set of 10 manuals

1961 STARRETT Tools Catalog 27 Detaled Info Pictures Using Starretts Dimention

Union Millwright*Millwrights*UBC*Hat Pin*PRIDE*+ 2 Starrett pkt charts mw819

GE Fanuc Series 15 Apendixes Operation Manual

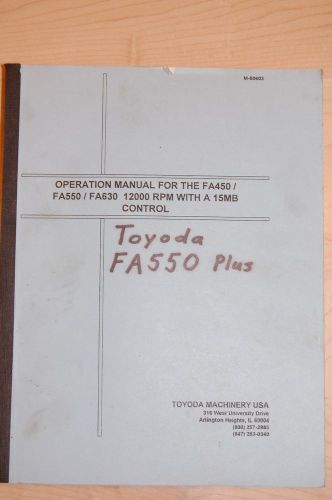

Toyoda Manual No. M-00603 Operation Manual for the FA450/FA550/FA630

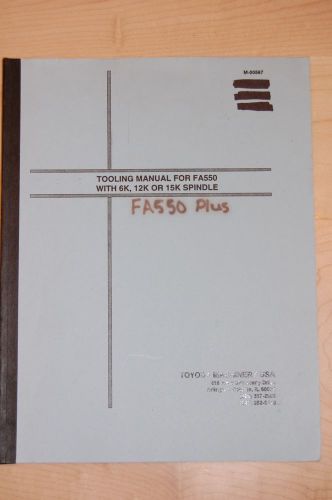

Toyoda Manual No. M-00567 Tooling Manual For FA550 With 6K, 12K or 15K Spindle

Brown & Sharpe Radius Wheel Truing Attachment Manual

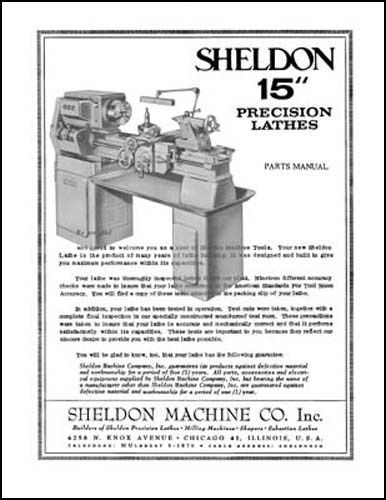

Sheldon 15 Inch Precision Lathe Parts Manual

People who viewed this item also vieved

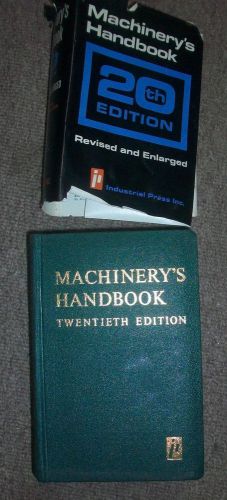

Machinery's Handbook 20th edition Machinist Tools Illustrated w/dustcover

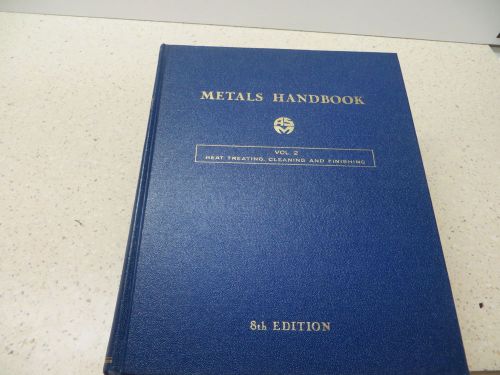

ASM METALS HANDBOOK VOL 2 HEAT TREATING CLEANING FINISHING

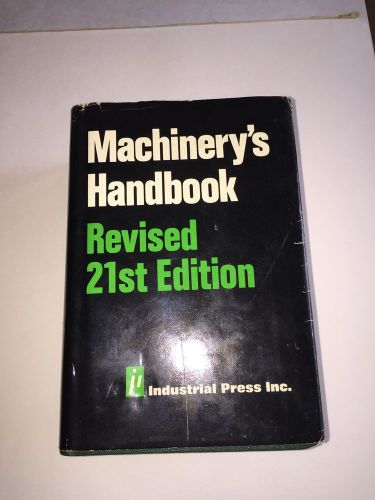

MACHINERY'S HANDBOOK 21st. EDITION 1980 EXCELLENT CONDITION

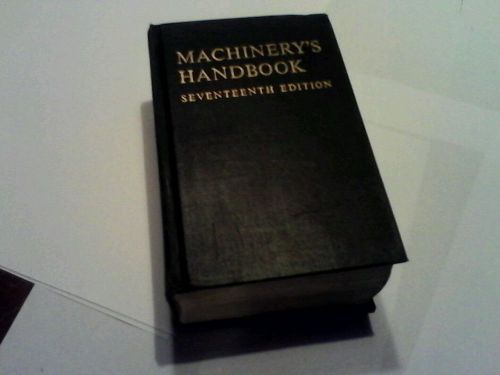

Machinery's Handbook student Edition 17th 1966 Machine Shop and Drafting

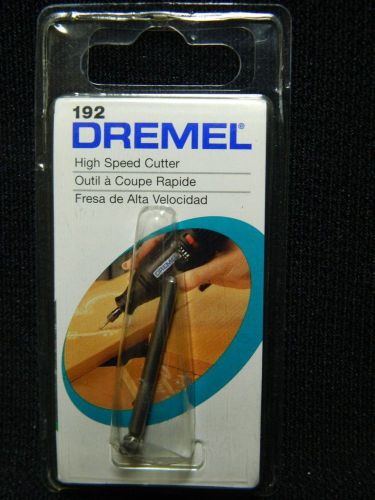

BRAND NEW Dremel 191 1/8" High Speed Cutter Use On Wood, Plastics, & Soft Metal

BRAND NEW Dremel 83322 1/8" Grinding Stone

BRAND NEW Dremel 190 1/8" High Speed Cutter Use On Wood, Plastics, & Soft Metal

BRAND NEW Dremel 196 1/8" High Speed Cutter Use On Wood, Plastics, & Soft Metal

BRAND NEW Dremel 192 1/8" High Speed Cutter Use On Wood, Plastics, & Soft Metal

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies