US $290

Directions

Similar products from Other Expendable Printing Materials

CTG Remanufactured Toner Cartridge (Alternative for HP 92274A 74A)

4 Liters NEW Eco Solvent ink for Roland Mimaki Mutoh CMYK Epson DX2/4/5/7

1 Liter ECO SOLVENT Fluid Printer Head Cleaner for Roland, Mimaki, Mutoh

HP Indigo Donaldson Ozone Filter Kit - CA290-10490

UV lLED Ink Epson DX head, Konica, Seiko, Ricoh nozzle with installed LED lamp

1L WHITE UV LED Ink Epson DX head, Konica, Seiko, Ricoh Excellent quality UK EU

Canon GP200 Black Toner Cartridge for Image runner 200/210 - 9600 page yield

Minolta EP - 1030/1031 Toner Compatible Toner Drum Cartridge Black 1 Cartridge

NEW Lot of 4 NCR Compatible Receipt / Journal Printer Ribbons (198682) - Generic

MBL-1029-01 BELT TIMING HO INDIGO

Kodak Adjustable Safelight Lamp Model A made by Eastman Kodak Company.

10 Clear Acetate (Plastic) Sheet 8.5" X 11" X .010 Dansco/Whitman Slides

HP Indigo TMB3 Board Assembly - EBE-2032-56

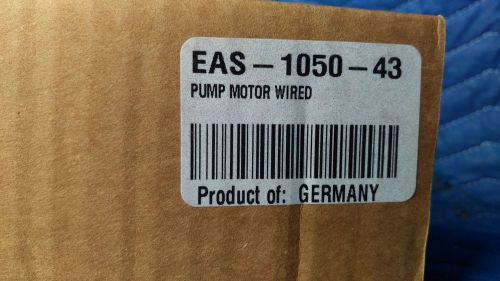

HP Indigo Pump Motor Wired - EAS-1050-43

HP Indigo Wiper 2, 4 Assembly MPX-4859-53

HP Indigo Ink Pump Unit Assembly - CA145-01420

HP Indigo Subassembly PCN and DSC - CA255-00011

HP Indigo BOARD ASSY RIO TESTED - CA157-00030

HP Indigo Donaldson Ozone Filter Kit - CA290-10490

HP Indigo Board PDB Assembly tested - CA255-00101

People who viewed this item also vieved

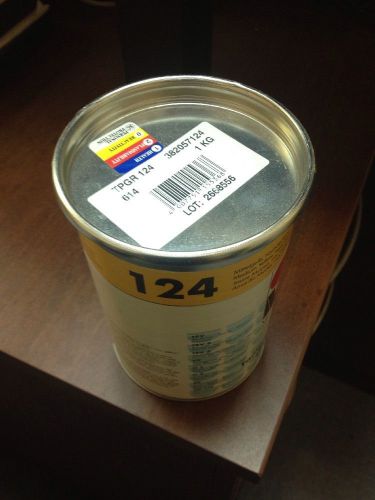

Marabu TPGR Pad Print Ink 124 Medium Yellow

Marabu TPGR Pad Print Ink 130 Vermilion

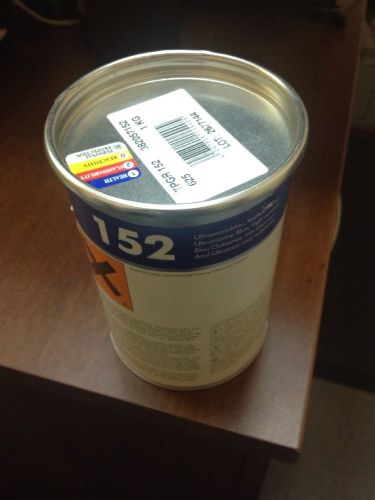

Marabu TPGR Pad Print Ink 152 Ultramarine Blue

GEN Opaque Russell Purple Plastisol Screenprint Ink QUART

Hydrographics Film True Weave Gold Carbon Fiber 32.5 sqft Water Transfer Print

Hydrographics Film Silver Clear Micro Carbon Fiber 32.5 sqft Water Transfer

HYDROGRAPHIC WATER TRANSFER PRINT HYDRO DIPPING FILM Red Flames Demon Skull fire

HYDROGRAPHIC WATER TRANSFER PRINT HYDRO DIPPING FILM Japan Cartoon Fish dip auto

HYDROGRAPHIC WATER TRANSFER PRINT HYDRO DIPPING FILM Zebra Print dip white black

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies