US $79.99

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Kelstar/Actega |

| MPN | UV-9058 | ||

| Model | UV Gloss Coating |

Directions

Similar products from Other Printing & Graphic Expendables

Richmond Direct Jet Cts Cartilage

Ink Knife / Spatula Set Used For Printing Press (Assorted Sizes)

New Steel Impression Cylinder Jacket for Heidelberg Quickmaster QM46-2 ,

DX5 Printhead Cap for Mimaki Jv3 Jv4,for Roland FJ-740/540,for MUTOH 800/8100

3D Stereoscopic Printing Pen (Blue) - For Arts + Crafts Printing, 3D Drawing

250 Business cards on Matte or Gloss Paper 12pt/350gsm Heavy Card Stock

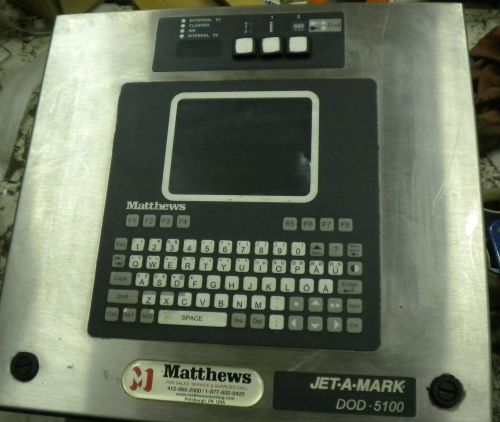

(00) Matthews Jet-A-Mark Printer Controller DOD 5100 Large Characters

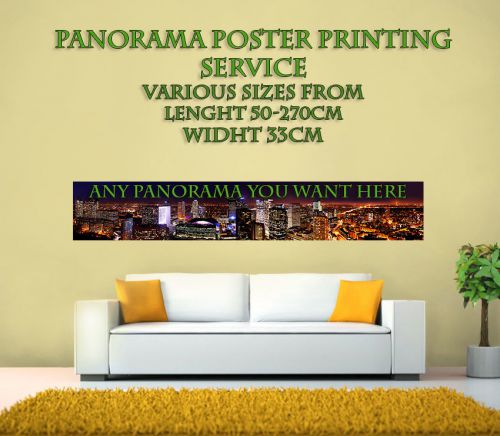

Panorama /Panoramic Poster Photo Printing Service, Any size from 50-270 cm x33cm

Seiko ink Cartridge ip-831 Magenra

Seiko ink cartridge ip-832 cyan

Seiko ink cartridge ip-833 yellow

Seiko ink cartridge ip-834 light magenta

Seiko Ink Cartridge Ip-835 Light Cyan

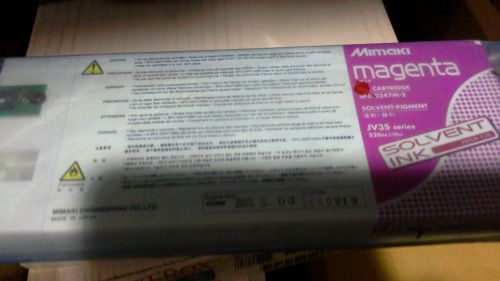

Mimaki Magenta Ink Cartridge .SPC 0347m-2

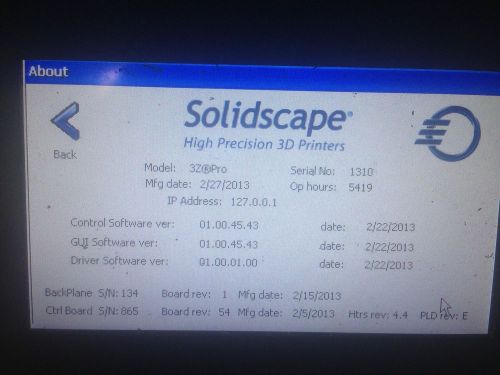

Solidscape 3Z Pro High Precision 3D Wax Printer

X-Rite Color QuickCal DTP34 Densitometer Handheld

X-Rite DTP20UV Pulse Color USB Spectrophotometer

5 Custom Digital Printed Sweat Shirt

People who viewed this item also vieved

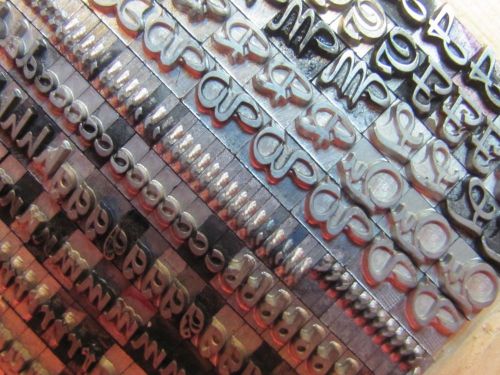

Letterpress Lead Type 18 Pt. Rondo ( TA ) w/ Alt's B37

Letterpress Lead Type 12 Pt. Rondo ( TA ) w/ Alt's B36

Letterpress Lead Type 12 Pt. Rondo Bold ( TA ) w/ Alt's B35

HP Indigo PIP Print Imaging Plate Q4407A For Press 3000-4000-5000 Series-(SEALED

3 Kits-HP Indigo Bobbin Wire with Dumper MKT-1106-06 Plus FREE Grids

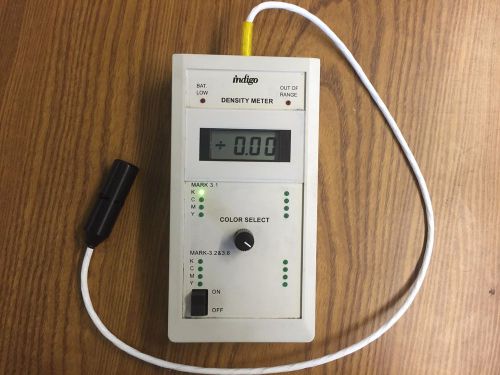

Hp Indigo CA254-00751 Ink Density meter

5PCS* All-glass syringe for printer ink filling Roland /Mimaki/ Mutoh printers

Mutoh VJ-1204/1604/1604W/1614, RJ-900C CR Encoder Sensor OEM

Original Epson Stylus Pro 3800/3800C/3850/3880/3885/3890 CR Sensor--2109662

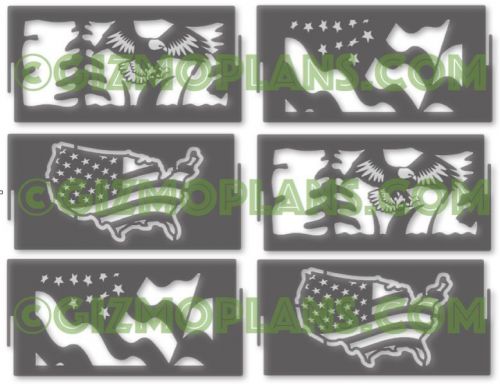

DXF Files USA Theme Hex Fire Pit CNC Plasma Laser dxf Images Vector cnc art

DXF Images BEER SERVED Sign CNC Plasma Laser Router dxf files cnc art

Swift Software 100,000 Clip Art CD ROM Windows 95 or Higher NEW Factory Sealed

X-Rite 331 Transmisson Densitometer Battery Operated

X-Rite CFS57U Counter Top 700 Paint Mix Match Formulation Instrument XRite CF57

x-rite DTP34 Spectrophotometer QuickCal Densitometer

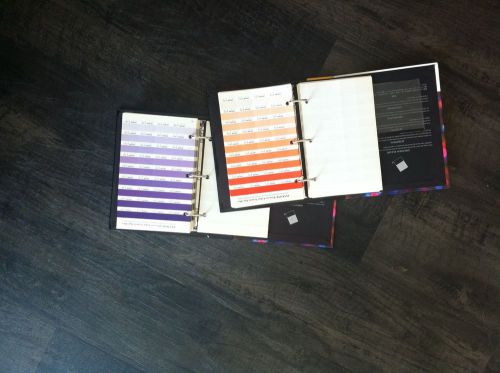

Pantone Boxed Set, Color Formula Reference, First Edition 2001, 1114 + Colors

Pantone Process Color System Specifier Set Volume 1 and 2 1991

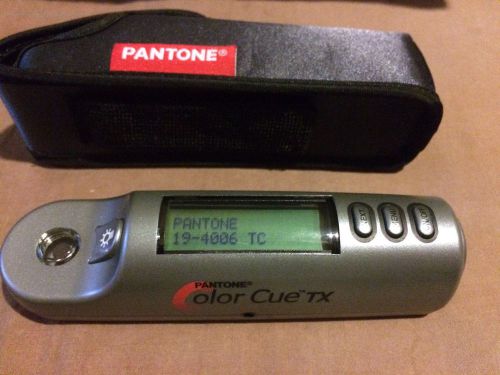

Pantone Color Cue TX Textile With Case

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies