US $190.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

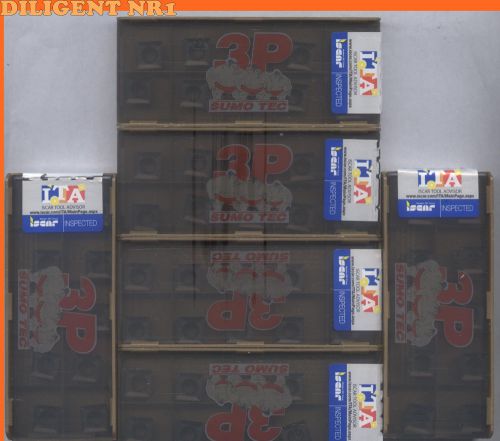

Brand | ISCAR |

| Material | Carbide Inserts | ||

| Model | HM90 APKT 1003PDR | ||

| SOME BOX MAYBE OPENED | INSERTS IS NEW NEVER USED | ||

| MPN | MILLING | ||

| SHIPPING | OFFER COMBINE SHIPPING | ||

| Primary Application(s) | Cast Iron, High-Temperature Alloy, Stainless Steel, Steel |

Directions

Similar products from Carbide Inserts & Face Mills

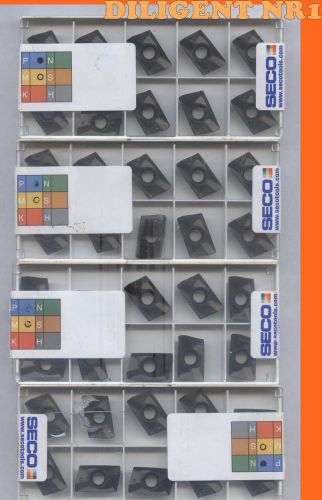

¤¤¤MILLING¤¤¤40pcs.SECO XOMX 180608R-M10 MP2500***

-LOT OF - ISCAR GIMY 630 IC 635 10pcs ( for Grooving and Profiling )

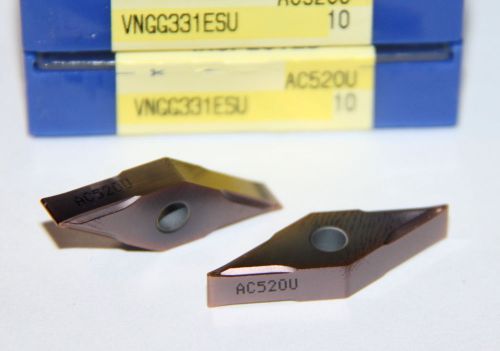

(100PCS) VNGG 331 ESU AC520U SUMITOMO *** 100 INSERTS *** FACTORY PACK *** VNMG

(100PCS) VNGG 330 ESU AC520U SUMITOMO *** 10 INSERTS *** FACTORY PACK ***

Kennametal 1.0" x 12.0" Solid Carbide Boring Bar C16 SCLPL3 (NEW)

(100PCS) VNGG 332 ESU AC520U SUMITOMO *** 100 INSERTS *** FACTORY PACK *** VNMG

** SALE ** WNMG 432 ESU AC520U SUMITOMO ** 10 INSERTS **

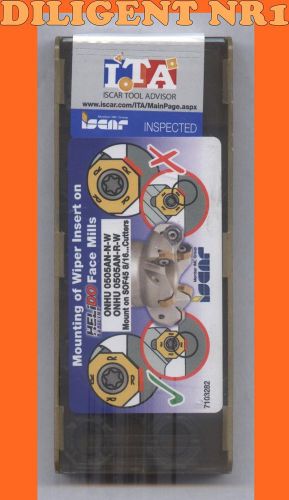

xxxFACE MILLINGxxx10pcs. of ISCAR ONHU 0505AN-R-W IC810++FREE SHIPPING++

(100PCS) XOMX 060208R-M05 F40M SECO *** 10 INSERTS *** FACTORY PACK ***

ISCAR GIMY 630 Carbide Insert IC20 1 pc lot

Seco WNMG 432 Turning Inserts 10pcs

10 pcs. Sandvik CCMT 06 02 02-PF 4225/4215 Inserts Brand new

5 KENNAMETAL INSERTS NEW A4G0505M05U04GMP KC5010 C7EB

Kennametal TNMP 432 K68 Carbide Inserts (10 Inserts) (M396)

* (100PCS) * CCMT 32.51 F1 TP2500 SECO *** 100 INSERTS *** 10 FACTORY PACK ***

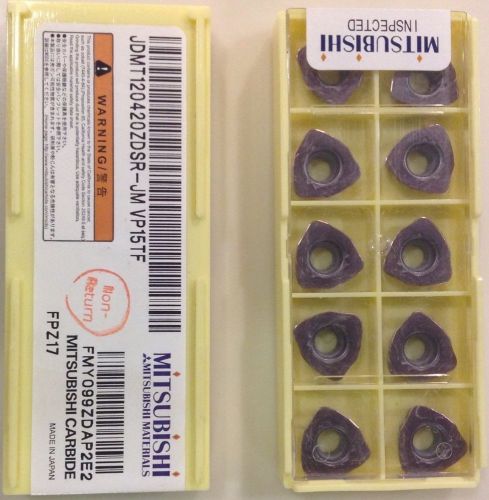

NEW NEW MITSUBISHI CARBIDE INSERT JDMT120420ZDSR JM VP15TF 10 PCS

10 pcs. Sandvik N123J2-0267-0002-GF 1125 Inserts Brand new

xxxMILLINGxxx60pcs. of ISCAR SPMT 100408TR-HQ-M IC808++FREE SHIPPING++

(100PCS) CCMT 21.51 F1 2151 TP2500 SECO *** 100 INSERTS *** 10 FACTORY PACK

People who viewed this item also vieved

INGERSOLL INDEXABLE 1.5" END MILL N16 2016 N6R S1 67113 D 5.25" OAL (LOC500) TS4

YG 1.5" ENDMILL 1-1/2 X 1-1/4 HSS L:8.162 4.5" OAL (LOC501) TS4

four 4 Flute HSS 1/8 " end mills 3/8" shank brand new

GREENFIELD 9.5mm 0.3740" HSS Straight Flute & Shank chucking reamer 25804

Machinist Bargain Lot Of Reamers - Cleveland, Morse, Butterfield, TFI, 3 Are New

OLD HOGGSON & PETTIS YALE BRAND NEW HAVEN, CONN. 1/2" H.D. NUMERIC PUNCH SET

Westward 10pc Gasket Punches set

Enco-450 Antique Metal Cutting Band Saw

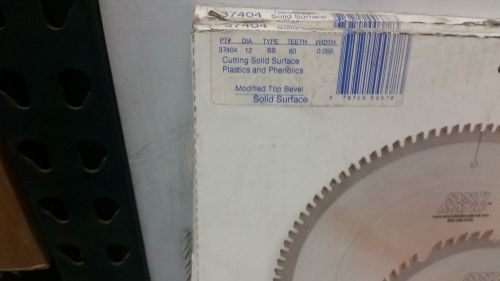

Systimatic Solid Surface Saw Blade #37404

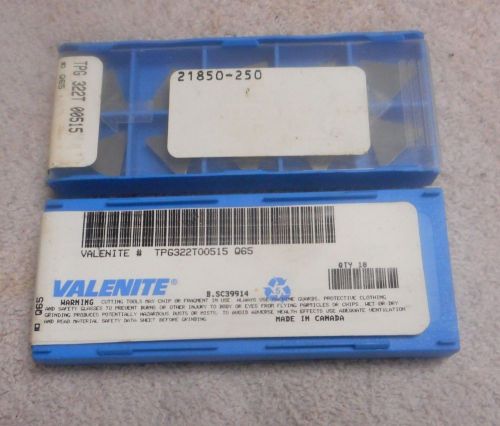

VALENITE CERAMIC INSERTS TPG 322 T 00515 GRADE Q65 PACK OF 10

Ceramcut-2 dng-432 6 pcs. ceramic inserts $13.00 each or best ofer.

Hougen 17124 3/4" x 3/4" Rotaloc Annular Cutter

Hassay Savage 3/4" Hex Broach, 3/4" Pilot

Lot of 12 Lathe Tool Bits Machinist Cutting Tools NEW Unused 1/2-1/4

American Carbide Tool Carbide-Tipped Tool Bit for Offset Threading, Right Hand,

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies