US $62,950.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

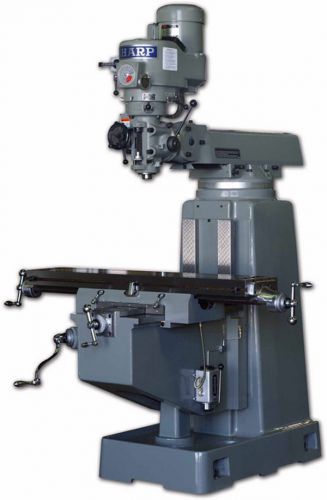

Brand | Victor |

| Model | 1654DCM |

Directions

Similar products from Tools for Milling Machines

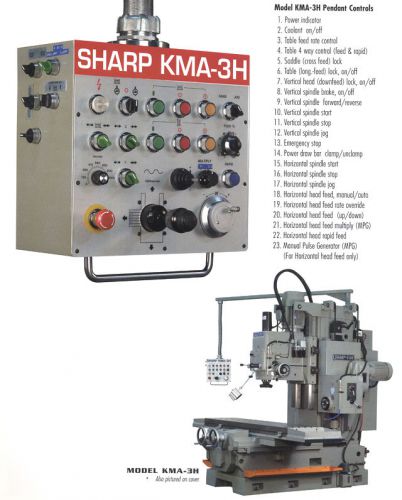

86.6" Tbl 20HP Spdl Sharp KMA-3H Horizontal Mill HORIZONTAL MILL, Bed-Type, 50 T

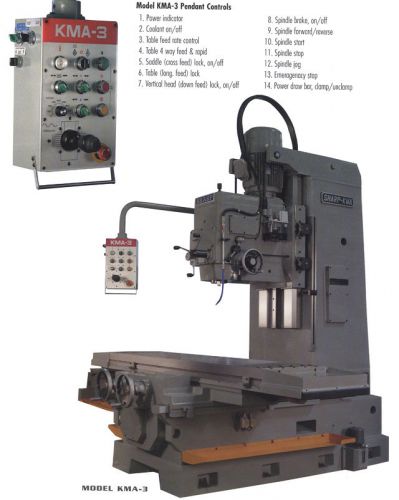

86.6" Tbl 20HP Spdl Sharp KMA-3 Vertical Mill VERTICAL MILL, Bed-Type, 50 Taper

75" Tbl 15HP Spdl Sharp KMA-2 Vertical Mill VERTICAL MILL, Bed-Type, 50 Taper

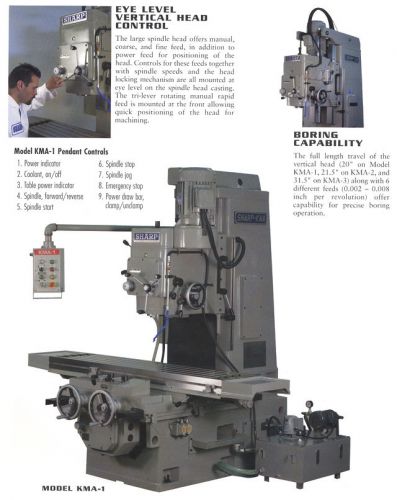

67" Tbl 10HP Spdl Sharp KMA-1 Vertical Mill VERTICAL MILL, Bed-Type, 50 Taper, 1

51" Tbl 7.5HP Spdl Sharp VH-3 Vert/Horz Mill VERTICAL MILL, 5 HP Vari-Speed Vert

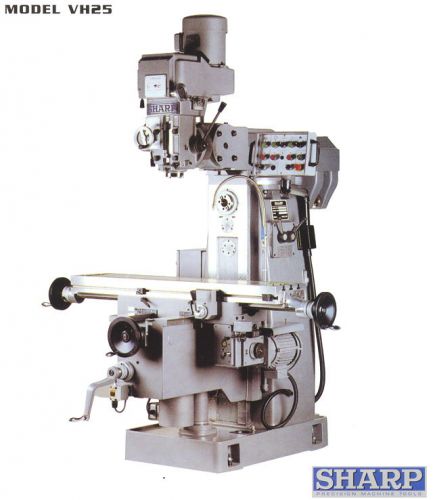

56" Tbl 5HP Spdl Sharp VH-25 Vert/Horz Mill VERTICAL MILL, 5 HP Vari-Speed Vert

50" Tbl 5HP Spdl Sharp TMV - Series II VERTICAL MILL, 5 HP Vari-Speed, #40 Taper

58" Tbl 5HP Spdl Sharp V-1 - 12" x 58" Tbl VERTICAL MILL, 5 HP Vari-Speed, #40 T

50" Tbl 3HP Spdl Sharp TMV - Heavy Pattern VERTICAL MILL, 3 HP Variable Speed

42" Tbl 3HP Spdl Sharp LMV-42 VERTICAL MILL, 3 HP Variable Speed

78.7" X 35" Y Victor 3090DCM NEW CNC MILL-VMC, Fanuc 20FA

61" X 30" Y Victor 2473DCM NEW CNC MILL-VMC, Fanuc Oi-M Control

48" Tbl 2HP Spdl Bridgeport Series I VERTICAL MILL, BRIDGEPORT POWER FEED

42" Tbl 2HP Spdl Bridgeport Series 1 VERTICAL MILL, TRAK 2-AXIS DRO

2V PRECISION VERTICAL TURRET MILLING

68.5" Tbl 10HP Spdl Cincinnati 310-16 UNIVERSAL MILL

10" W Moore ROTARY Tbl, HORIZONTAL

65.25" Tbl 10HP Spdl Cincinnati 310-14 HORIZONTAL MILL, 14" x 65" Tbl, Independe

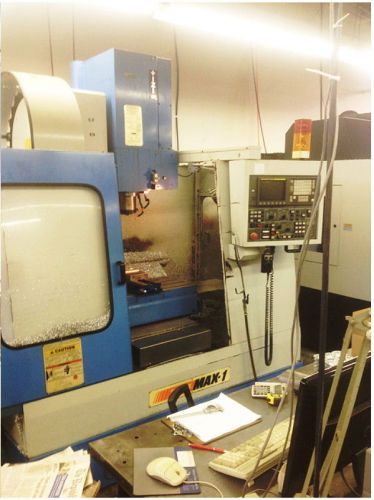

1999 SUPERMAX MAX-1 REBEL CNC VERT MACH CENTER w/FANUC 0M. MANUAL PULSE GENERATR

1998 HAAS VF-3 CNC VMC, WIRED FOR PROBE, FULL 4 AXIS, COOLANT THRU, ETC, ETC.

People who viewed this item also vieved

Schauer LA10 SPEED LATHE BOX OF PARTS

LOGAN LATHE 12 IN FEED CHANGE GEAR CLUSTER COMPLETE

LATHE BORING BAR LTBAP-10-2 USA STK1561

Centron M3 "Ded-Tru Style" Centerless Grinding Fixture for Surface Grinder

Landis Universal Grinder BU-6240

Harig Super 612 Surface Grinder

Versatapper II Supreme No.6100 8383-25

HeliCoil R5326-14E R-Pk Sav-A-Thread M14X1.45 Inserts(6Pk)

ACORN THREADING DIE, 7/16-20 HSS, WIDELL #3 BLANK, 1 1/4" OD

Antique Moore Wood Work Bench / Tool Cabinet ~ Beautiful Condition!

Di-Acro Spring Winder Diacro Coiler Torsion Compression Extension

Luma Electric Equipment Model 60 Portable Metal Etcher

Wysong Mechanical Power Shear, Model 1025

Cincinnati Mechanical Power Shear, Model 1810

Sunnen honing machine catalog, 1976

Inwesco Corporation SC480- 4" Electrical Pipe Duct Conduit Test Mandrel

Vibratory Parts deburring machine

1 1/2 " s 1 1/2 nps 2 1/8-20 and 2 1/2-12 die chasers lot

1" sj and1"s die head chasers lot NOS

GEOMETRIC Die Head Ds-N K33337 Loc: P 1-3

Erowa ER-012299 ITS Rapid-Action Chuck NSF on Plate FG39

Erowa ER-012297 ITS Rapid-Action Pneumatic Chuck NSF on Block FG38

Erowa ER-012299 ITS Rapid-Action Pneumatic Chuck NSF on Plate FG37

Bolton Tools 13 3/4" Dual Column Metal Cutting Band Saw GK4220

Delta Intl, Mdl 20 Metal Band Saw 3-Phase, 2 hp. Runs on Static Phase Converter

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies