US $2700

Directions

Similar products from Shafts

300w ER11 3000-12000RPM DC Brushed spindle motor&Power Supply&mount bracket CNC

400w ER11 3000-12000RPM DC Brushed spindle motor&Power Supply&MACH3

1HP 0.8kw 24000RPM ER11 Woodworking AC Spindle motor 4 bearings 65mm 220VAC 6A

1.5HP 1.2kw 24000RPM ER11 Woodworking AC Spindle motor 4 bearings 80mm 220VAC 8A

500W ER11 3000-12000RPM DC Brushed spindle motor&PWM

400w ER11 12000RPM BLDC spindle motor&PWM MACH3 Driver

400w ER11 12000RPM BLDC spindle motor&PWM MACH3 Driver controller&mount bracket

80MM ER11 COLLET MOTOR SPINDLE 1.5KW WATER-COOLED ENGRAVING MILLING GRIND E

3HP 2.2kw 24000RPM ER20 water cooling Woodworking AC Spindle motor 85mm

Setco SPL Type 4304BY Precision Spindle 5000rpm

2HP 1.5kw 30000RPM ISO20 3 bearings Automatic Tool Changes ATC Spindles

3HP 2.2kw 30000RPM ISO20 3 bearings Automatic Tool Changes ATC Spindles

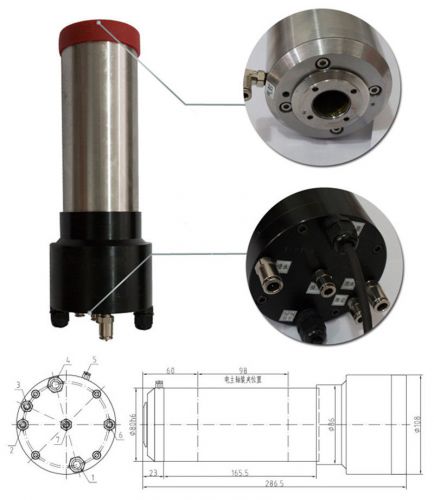

7HP 5KW 18000rpm BT30 Permanent Torque Automatic Tool Changes ATC Spindles

9HP 6.5KW 24000rpm BT30 Permanent Torque Automatic Tool Changes ATC Spindles

7HP 5KW 9000-15000rpm BT30 Permanent Power Automatic Tool Changes ATC Spindles

BT50 45 degree inside screw 4 Petal Clamp Pull claw for cnc Spindle NEW

3.0kW IMT Classic 80 M15 60,000rpm Grinding Spindle CNC ID HSK 25C

5HP 4KW 9000-15000rpm BT30 Permanent Power Automatic Tool Changes ATC Spindles

7210HP 7.5KW 18000rpm BT30 Permanent Torque Automatic Tool Changes ATC Spindles

10HP 7.5KW 18000rpm BT30 Permanent Torque Automatic Tool Changes ATC Spindles

People who viewed this item also vieved

KENNAMETAL Shell Mill Adapter Taper Shank CAT50 2" Pilot 4.88" Nose Dia |LK2|

JACOBS 7316 A0304 MORSE TAPER ARBOR MT 3 / JT 4 USED FREE SHIPPING IN USA

CORMAN / RMC TOOLING PART # NL-810 7/16-20 THREAD LOCK PIN

CORMAN / RMC TOOLING PART # STC9, 10-32 THREAD SCREW

RICHMILL ULTRA LOCK MILLING CHUCK BT BT40-CHB1-1/4-105 TOOL HOLDER HOLDERS LMSI

RICHMILL ULTRA CHUCK CT50 CAT50 TOOL HOLDER haas fadal mazak mori cnc mill LMSI

NEW DODGE 120513 EX2-7/16-KW QD 2-7/16 IN BUSHING B350741

Valenite CAT50 74BC7775 Flynn 65T Precision Boring 4" for 3/4" Square Round Tool

"Made in U.S.A." Vtg JACOBS CHUCK 33 DRILL CHUCK WITH 5/64 TO 1/2 CAPACITY TOOLS

3/8" ANGLE DRILL ATTACHMENT With Chuck #1447

SECO 87699 R220.29-0.400-10.5A 4" 4.00" 5 Insert Indexable Copy Face Mill 21T

SECO 87699 R220.29-0.400-10.5A 4" 4.00" 5 Insert Indexable Copy Face Mill 2i

Sunnen Maqndrel No. 395C3 Range .395" to .410"

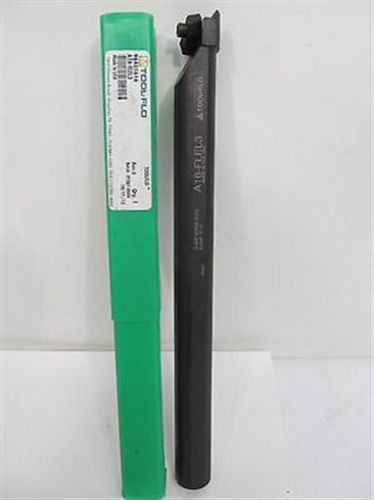

Tool-Flo A16-FLEL3, Indexable Threading Toolholder - 96401616

SCHRADER BELLOWS 53083-1000 VALVE 200 PSI USED (B8)

FALCON QUICK CHANGE TISA-6-20 SHELL MILL ADAPTER

BILZ WEN2 M20 QUICK CHANGE ADAPTER

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies