US $150

Directions

Similar products from Sanding Discs & Sandpaper

3" Medium Scotch Brite Roloc quick change Disc Roll-on TR (25 Discs)

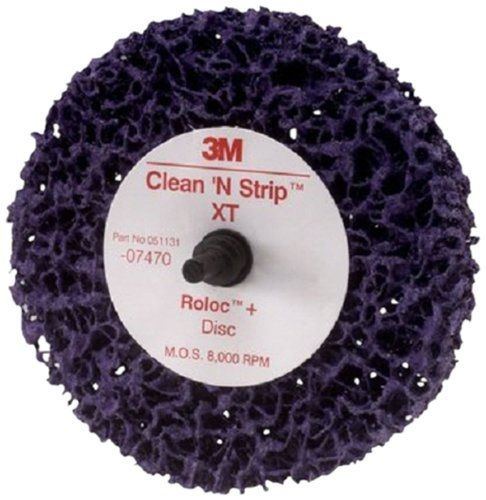

Scotch-Brite(TM) Roloc(TM)+ Clean and Strip XT Disc 07470, Roloc Quick-Change

10pcs Coarse 3x1x1/4 KEENbrite Non woven interleaf Mounted Flap Wheel #75047

Norton, Blue Fire Flap Discs, 77696090172, 3" 60 Grit, Type 3 ( 10 in box )

1 BX/10ct Merit Grind-O-Flex Abrasive Flap Wheel 1" AH 180ARB 6" X 1/2" 180 g

1 BX/10ct Merit Grind-O-Flex Abrasive Flap Wheel 1" AH 240ARB 6" X 1/2" 240 g

3M Type C Disc Closed Coat Aluminum Oxide Lot of 10 80 Grit PN4 XY FREE SHIPPING

Merit 120 Piece Cartridge Roll CR Test Kit (Pack of 1)

Century Drill and Tool 8411 Metal Abrasive Cutting and Grinding Wheel 1-1/2-I...

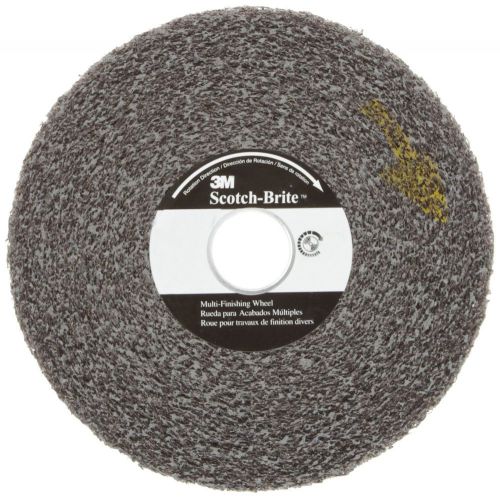

Scotch-Brite(TM) Multi-Finishing Wheel Silicon Carbide 6000 rpm 6 Diameter x ...

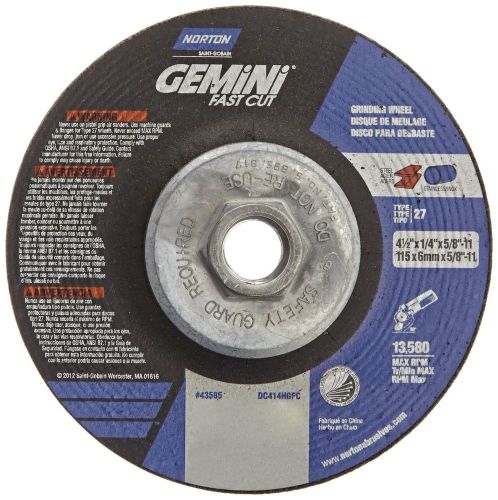

Norton Gemini Fast Cut Depressed Center Abrasive Wheel Type 27 Aluminium Oxid...

Scotch-Brite(TM) High Strength Disc Aluminum Oxide 8 Diameter Medium Grit Mar...

Mitchell Abrasives 50-C Round Crocus Polishing Cord .070" Diameter x 25 Feet

Festool 496982 P220 Grit Granat Abrasives Pack of 100

10 Pack 4-1/2" x 7/8" Black Hawk Zirconia Grinding & Sanding Flap Discs T29 (40

3M 01407 Green Corps Roloc Green Disc

Keen 2" 240 GRIT ROLOC sandpaper sanding DISC #72213, 50 pack

3M 987C Fibre Sanding Disc, 4 1/2 In, 60 G, Pk 25 G4446766

3M Hook and Loop Disc Backup Pad, 8" Diameter, QTY 1, 918 |KO1|

3M Stikit Coated Finishing Discs Ceramic, 12000 RPM, QTY 100, 51232 |KO4|

People who viewed this item also vieved

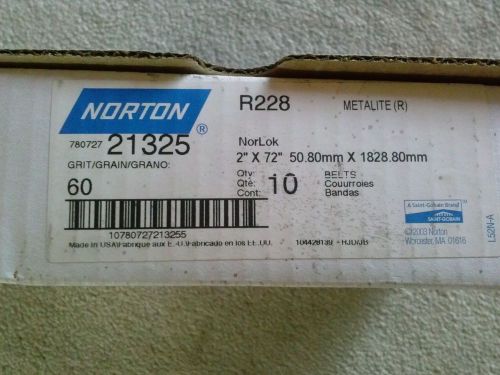

NORTON 2" x 72" Sanding Belts (QTY 10)

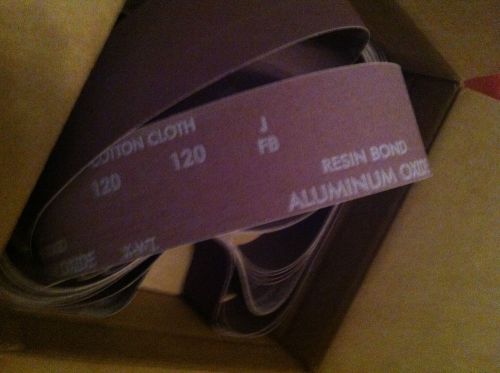

ALUMINUM OXIDE RESIN CLOTH 90 / 2.5" X 132" GRIT 120 / 6 TOTAL BELTS

Lot of 4 Abtex Silicon Carbide Filament Disc Brush 14in. 0560900

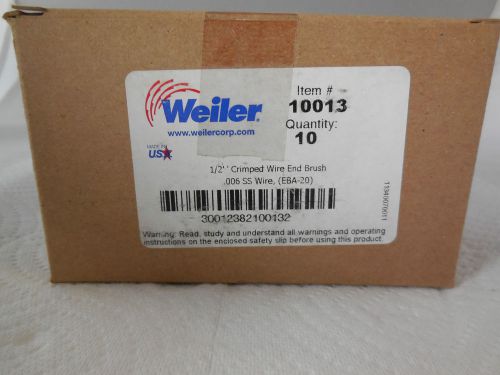

WEILER 10013 CRIMPED WIRE END BRUSH SS WIRE (BOX OF 10)

2 PC TEMPERED STEEL WIRE BRUSH WITH WOOD HANDLE SET

12" DIA. X 1' WIDE X .020 X 1" ARBOR FELTON WIRE WHEEL #132017

LOT (Quanity 5) SAIT Grind A24R-BF Type 27 Right Angle Grinder

LOT OF 10... 1/16th X 7/8 X 6 inch 2 In 1 Premium TRYOLIT CUTOFF WHEELS

Trak-Kut-XX Abrasive Cutting Wheel PN 701050 16" x 1/8" x 1" 4200 rpm Lot of 3

Northern 4" Cutoff Saw Blade - 10 each

Box of 100 BOSCH 5" Sanding Discs 8 Hole Hook And Loop P180 Grit NEW RS181

Abrasive Metal Grinding Wheel 4.5" x 1/4" x 7/8"

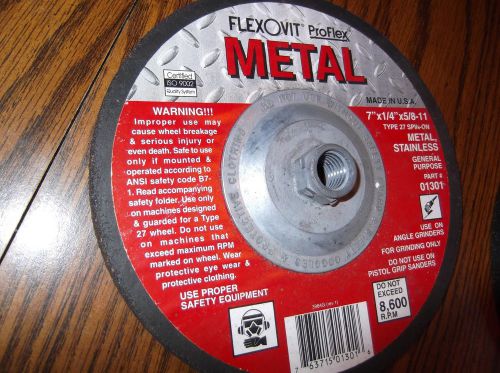

FlexOVit ProFlex Cutting Metal and Stainless 7" x 1/4" x 5/8 - 11 Grinding Wheel

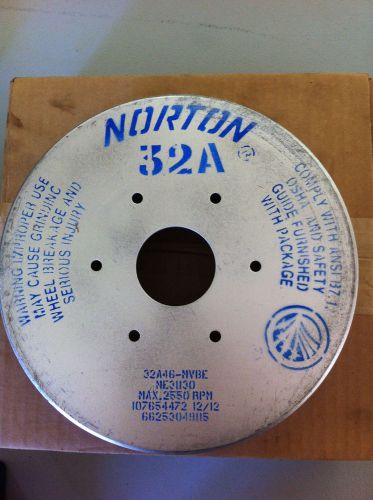

Norton 32A46-MVBE Grinding Wheel 66253049115 2550 RPM

REGIS Royal Cut K-12 Diamond Dresser

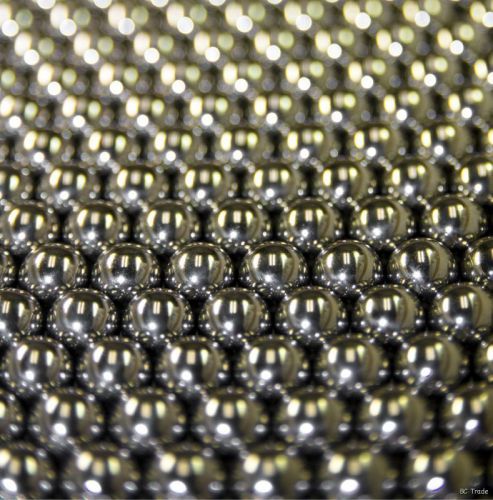

5 LB Pounds 5/32" Stainless Steel Ball Tumbling Media / 8800 Pieces

Sunnen Precision Graded Honing Stone XHB-13

Buehler Ltd. 43-1502 Two-Speed Metal Polisher, Metallurgical Apparatus

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies