US $291.99

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | HY |

| UPC | 190080036713 | ||

| MPN | 100367101 |

Directions

Similar products from Stepper Motor Driver Boards & Modules

USB DB25 6 Axis Breakout Board Interface Adapter F PC Stepper Motor Driver Board

CNC Single Axis TB6600 0.2-5A Two Phase Hybrid Stepper Motor Driver Controlle LB

6-24V Mini DC Motor Speed Control Controller Board Adjustable Speed Range 1-100%

SIGMA SIGMAX PACIFIC SCIENTIFIC STEPPING MOTOR MODEL E21NSFT-JDN-NS-02

USED Mitsubishi AC Servo Motor HC-KFS23K-S9 2 month warranty

AMERICAN PRECISION M232-04, STEPPER MOTOR 4.3VDC 1.8AMPS MADE IN USA

Minebea-Matsushita Stepping Motor MODEL NO. T5425-01 / 23KM-K218-01

3rd Gen Professional TB6560 Driver & 4 Stepper Motor 425 Oz-in &PSU,Gcode Record

CNC Professional 4 Axis TB6560 Driver+Box & 4x 3Nm Nema 23 Motor, Gcode Recorded

CNC Professional 3 Axis TB6560 Driver+Box & 3x 3Nm Nema 23 Motor, Gcode Recorded

CNC Professional 3 Axis TB6560 Driver Set & 2.1Nm Nema 23 Motor, Gcode Recorded

NEW Mitsubishi Servo Motor Retarder HC-KFS43G2K-S42 2 month warranty

CNC Professional 4Axis TB6560 Stepper Driver Full Kit & Motor/PSU/Keypad/Display

USED Mitsubishi AC Servo Motor HC-KFS13BG1 2 month warranty

New 3 Axis CNC Stepper Motor Driver TB6560 Set + LCD Display + Handle Controller

3 Axis CNC Router TB6560 Stepper Driver + Display + Control Pad + Aluminium Box

3Axis CNC Router TB6560 Stepper Driver Set + Display + Control Pad 0.5-3.5A Peak

yokogawa position controller PC10021,199FS12664E9

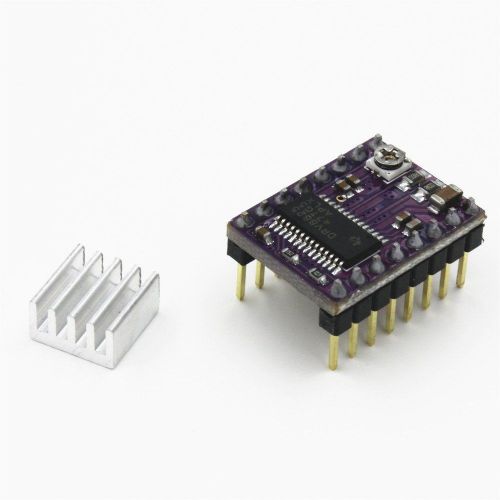

5X Arduino DRV8825 stepper motor driver Stepstick RepRap Prusa Mendle 3D Printer

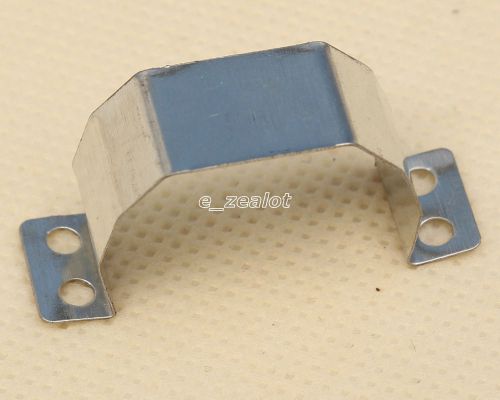

10pcs Motor Bracket Metal Bracket Fastening for 130 180 Motor Perfect

People who viewed this item also vieved

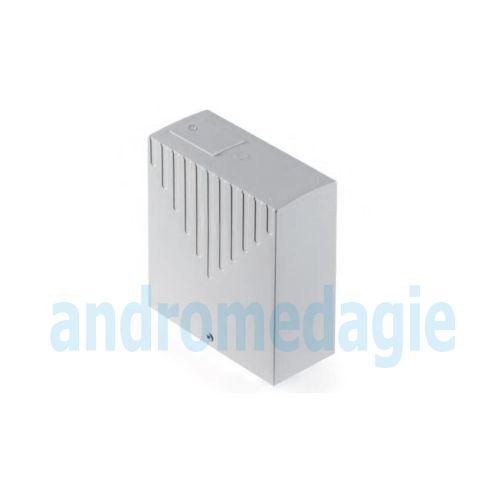

CONTROL UNIT 230V NO-RADIO home automation systems Mowin Comunello

BOTTOM HUNG KIT SCREW APRICOLOR connection to the window motors series Varia

FURNAS REPLACEMENT PART CONTACT KIT 75CD42 NEW!! All three poles

General Electric GE BCLF01 BCLF01 Auxiliary Contacts NO, NC

NEW Allen Bradley 700-R800A1 700R800A1 control relay 8 n.o. industrial BNIB

RKC REX-C400 C400FJ02-M*NN C400FJ02MNN Controller C

Parker Compumotor A S-Drive Control C

Allen Bradley Contactor 100-B110ND3 Series B

NEW SPERRY VICKERS, COIL, 316011, 115VAC 60HZ, NEW IN FACTORY PACKAGING,

NEW SPERRY VICKERS, COIL, 317769, 115VAC 60HZ, NEW IN FACTORY PACKAGING,

GE General Electric ck09be300 MOTOR STARTER CONTACTOR

Square D Contact/Starter, Class 8536, NEMA size 1

NEW YC-CK-EH100 FITS ABB/ASEA REPLAMENT CONTACT KITS 3P KZ100 EH100

GE Definite Purpose Contactor CR353EE3BB1AB 50 AMP 3 Poles Coil 208/240V

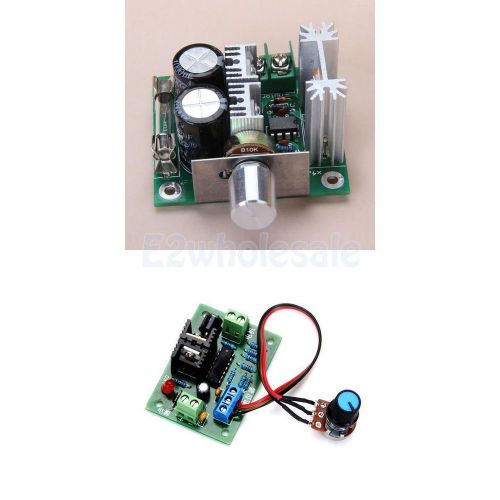

3x DC 12 - 24V 3.2A Motor Speed Control PWM Controller

PWM DC Motor Speed Controller with Knob +Motor Speed Control PWM Controller

5pcs DC Motor Micro Motor Miniature D21mm X H25mm 21*25

New Panasonic G Series Speed Controller DVSD48BL - 100-120V AC - SD48

Dayton Permanent Magnetic DC Gearmotor Speed Control 6A191

GRAYHILL STANDARD ENCODER 4-PIN 128 CYCLES QUADRATURE 61K128

Pran Systems DC Dual 25A Controller 11 in and 12 Out Converter Ambulance Parts

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies