US $250

Directions

Similar products from Hook-up & Wrapping Wires

Verizon (CDMA/EVDO) Certified, 3G, IR, HD (GC-SPTi-KT)

Sewell Male to Female Extension Cable / Stereo Audio 6 ft 3.5mm (SW-30350-6)

Pyramid 1000 Watt 20 ft. Amplifier Installation Wiring Kit (1072-PBIN3)

264 Feet or 80.46 m 30 AWG Stranded Copper Model Railroad Layout Hook Up Wire

Electronix Express - Hook up Wire Kit (Stranded Wire Kit) 22 Gauge (25 Feet)

Extech Electronic Test Lead Kit Multi Meter Wires Connector Clamps Tool Tip Clip

Remington Industries 20UL1007STRWHI UL1007 20 Awg Gauge Stranded Hook-up Wire,

Automation Direct C5E-STPOR-S7 Cat-5E Patch Cable, 7', Grey

Axis - Indoor/Outdoor Workshop Extension Cord (100ft)

16/2 Duplex Marine Cable, Tinned Copper, UL 1426 100'

1/0 AWG 1C Type P Power Cable, 2KV

535 MCM 1C Type P Power Cable, 2KV

DJI Phantom 3 Standard with 2.7K Video Camera Quadcopter Drone

Belden 84303 RG303 M17/111 550ft spool@ $1.95/ft

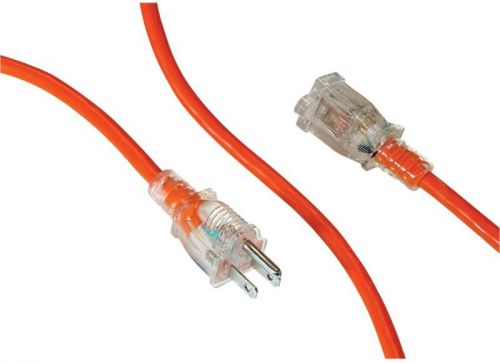

12/3 SJTW 100' Red w/ Lighted Ends Extension Cord (UL)

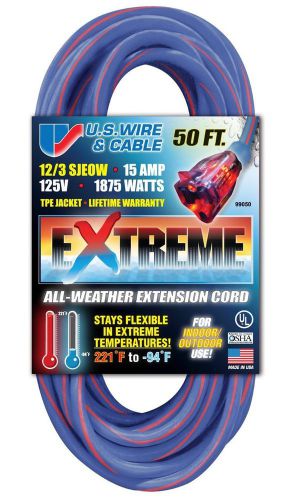

12/3 50-Foot SJEOW TPE Cold Weather Extension Cord Blue with Lighted Plug

Socapex 19 pin, 6-circuit, 20A to (6) L5-20, Break-Out - Black - 6 FEET LONG

4/4 SOOW Yellow Portable Cord 600V Non UL

People who viewed this item also vieved

250ft Electric Cable 10/3 600v 30a STW

LOT 50 NEW RAYCHEM ESC-2/A B50 END SEALING CAP #6-3/0 1/C 1KV CABLE B205584

NEW PASTERNACK E-100316-5 700FT 21AWG CL2X AWM STYLE 1354 CABLE-WIRE D477096

AMPHENOL- SINE SYSTEM HM18EEG16-MPS/FPS-A CABLE ASSY 32P 10FT - NEW - FREE SHIP

Assorted Fiber Optic Patch Cables Lengths NO Connections Sold as Lot of 10

ANDREW F4A-PDMDM-8-USA 8' JUMPER

140' Prodelin RG-331/U 5/8" 50-Ohm Hardline Coax Cable

T&B 251-31446-36 COPPER BUS BAR 1925/24 DIE INDEX 112H; COLOR-KEYED

PhD TOM THUMB AVCF 1X4 AIR CYLINDER

FESTO FEN-20-25 STANDARD CYLINDER

1000' Roll 3/16" ID Flexible Armored Cable 304 Stainless Steel Full Square Lock

Magnet Wire, Enameled Copper, Red, 38 AWG (gauge), 130C, ~1/16 lb, 1210 ft

B And C 21SW152-8 B&c 21" Sub Neo Magnet 6" Coil 8ohm 1400 (21sw1528)

Pickup Winders Kit#12 - 42 Red & Natural 42 Plain 42H Formvar Copper Magnet Wire

Pickup Winders Kit #11 - 42 PE, 42H Formvar, 43 PE, 43H Formvar AWG Magnet Wire

Rst4-rft-637/3m 600003350 Cordset Micro M12 4 Pole

RST 4-RKT 4-602/3M Cordset M12 Male to Female 4 Pole 3m 610001493

RSRK 40 839/10M Lumberg Automation / Hirschmann 500003212 Cordset

2 pcs strain relief bushing 9/16" Panel mount cable clamp entrance protector

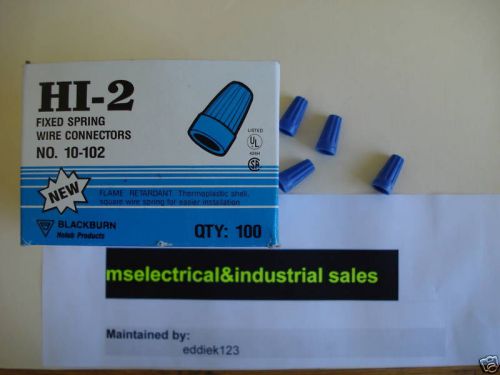

100 pcs. BLACKBURN HI-2 FIXED SPRING WIRE CONNECTOR 22-14AWG

25 PCS WAGO 3 PORT LUMI-NUTS 873-953 LUMINAIRE BRAND NEW! (25) PIECES!

10 X 0.3mm 50g Tin Lead Soldering Solder Wire Rosin Core Tin(Sn) Lead(Pb) 63/37

New 0.3mm 50g Tin Lead Soldering Solder Wire Rosin Core Tin(Sn) Lead(Pb) 63/37

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies