US $360.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | ISCAR |

| SOME BOX MAYBE OPENED | INSERTS IS NEW NEVER USED | ||

| Model | ADKT1505PDTR-RM | ||

| SHIPPING | OFFER COMBINE SHIPPING | ||

| MPN | MILLING | ||

| Primary Application(s) | Cast Iron, High-Temperature Alloy, Stainless Steel, Steel | ||

| Material | Carbide Inserts |

Directions

Similar products from Carbide Inserts & Face Mills

SANDVIK VBMT160408-PM 4215 20PCS

3/4" ISCAR MTENNS-123 Lathe Tool Holder TN_33 Carbide Inserts (M 965)

MACHINIST TOOLS LOT CARBIDE INSERTS 43 PIECES MISC SIZES & BRANDS ALL UNUSED

Carbide Insert TNRA-550-0310 CA17273 CA310 QTY 5 FREE SHIPPING

Kennametal carbide insert lnmr501432 FREE SHIPPING

Hertel TNMG322R HT10 Carbide Turning Inserts Qty 10 FREE SHIPPING

KENNAMETAL DCGNR 854D TURNING TOOL HOLDER CNMG-432

¤¤¤UNOPENED PACKS¤¤¤40pcs. of SECO SPMX 1504AP-75 F40M++FREE SHIPPING++

WALTER LNHU 100508-F57T WKP35S 10PCS

KENNAMETAL CARBIDE INSERTS , DNGP 431K , KC7310 , 10 INSERTS

KENNAMETAL CARBIDE INSERTS , DNGP 432K , KC730 , 11 INSERTS

KENNAMETAL CARBIDE INSERTS , DNGP 432K , KC7310 , 5 INSERTS

KENNAMETAL CARBIDE INSERTS , VNMP 331 , KC850 , 8 INSERTS

50pcs - FREE SHIPPING SANDVIK 880-0503W08H-P-GT 4044 50pcs

KENNAMETAL CARBIDE INSERTS , VNGP 3305 , KC730 , 4 INSERTS

People who viewed this item also vieved

2-1/2" Diameter Valenite Face Mill With Inserts.

LOT ( 3 ) CARBIDE & ROUGHING ENDMILL MILLING LATHE CNC CUTTING TOOL ROUGHER BITS

Concave knurling wheel - C type R3.0 Pitch 0.8

Knurling tools for Auto lathe - 8x8mm shank size

Roper Whitney 8 ton punch press Model 34

Roper whitney/diacro mate .692x.756"punch die 1 set 15/16" shaft die O.D 2.25"

Reduced Shank Chucking Reamer .8858, eight FLT

Cincinnati Milacron Heald Borematic, 200's, 300 and 400's Service & Parts Manual

Heald 121, 122-124, Borematic Boring Machine, Service & Repair Parts Manual 1949

Kennametal Kyon Inserts SNGA 433 T0820 KY 3500

Kennametal Kyon inserts SNGX453 T0820 KY 3500

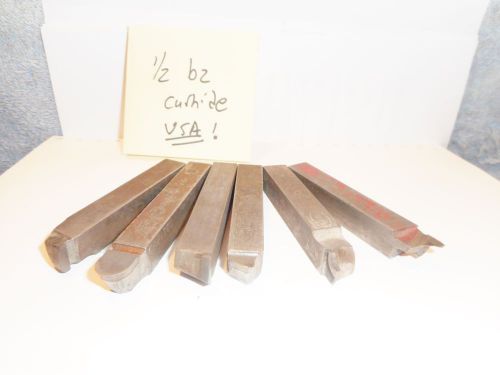

Machinists 2/27 USA Preground Brazed Carbide Tool Bits 1/2 "

Machinists 2/27 Iconic USA 1" D Forged Die Wrench for 1" Dies

DUMONT CO. MINUTE MAN KEYWAY BROACH AND BUSHING SET 10-10A w/ WOOD BOX

RotaLoc Plus Cutter, 1-3/16" X 1" DOC 17238

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies