US $460

Directions

Similar products from Carbide Inserts & Face Mills

* 40pcs * FREE SHIPPING * ISCAR LNKX 1506PN-N MM IC 928 40pcs

SANDVIK R245-12 T3 E-PL 530 30PCS **

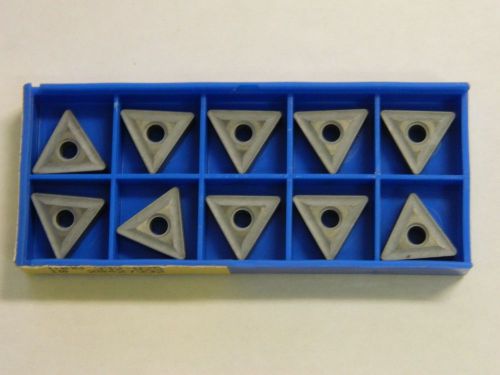

Baildonit TPG 322 NT35 TiN Carbide Insert

Hertel HMX00425E ODG62361SGB HC235M Carbide Inserts - Box of 10

Tool Flo FLAS-3R5 AT3 Threading Inserts

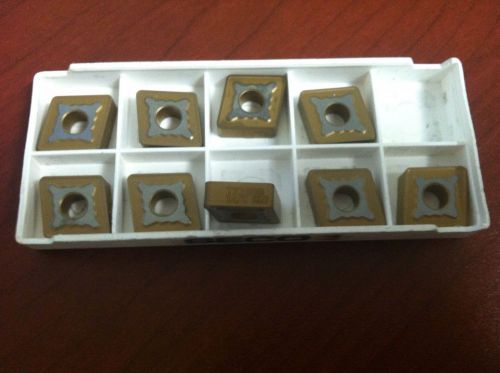

Seco #17741 CNMG120412-MR7 CNMG433-MR7 TK1000 Carbide Turning Inserts

Korloy TNMG 332-B25 C2 Carbide Inserts

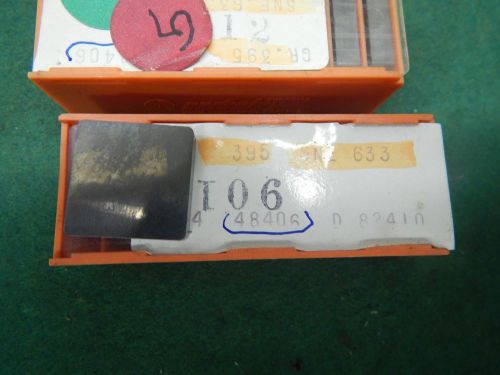

Carbaloy SNE 633 395 Carbide Insert

ALLIED MACHINE & ENGINEERING GEN3SYS 7C229P-105AS Spade Drill Insert

Carbaloy CNMP 542 E-16 560 Carbide Insert

TUNGALOY XXMU16X508PRMJ AH120 Milling Inserts

Dijet SNC 63 A3 Carbide Insert

SANDVIK DNMG110408-MF DNMG332-MF 2015 CARBIDE TURNING INSERT

Valenite SSN 64C Carbide Insert Seat

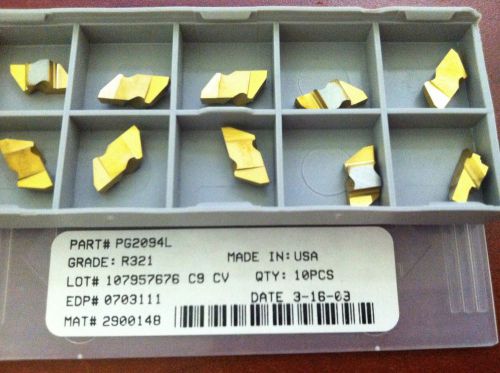

RTW PG2094L R321 Indexable Carbide Grooving Inserts

RTW TNMC 32NGR .047 G.W. CY16 Carbide On-Edge Threading Inserts 771750

Valenite DNMP332-1W DNMP110408-1W 929 Carbide Inserts

* 50pcs * FREE SHIPPING * ISCAR CNMG 160612-NR IC 8250 ( CNMG543-NR) 50pcs

20 pcs. Mitsubishi GY2M0400G020N-GS VP20RT grooving inserts 4 mm GY2 N123H2-0400

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type E, 2 1/8" x 5", Uncollared, Used

Keyway Broach Bushing Guide, Type E, 2 3/8" x 6", Uncollared, Used

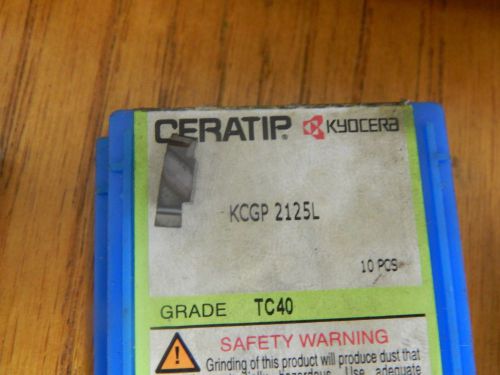

Kyocera Ceratip KCGP 2094L TC-40 Ceramic Insert .094" Wide

Kyocera Ceratip KCGP 2125L TC-40 Ceramic Insert .125" Wide

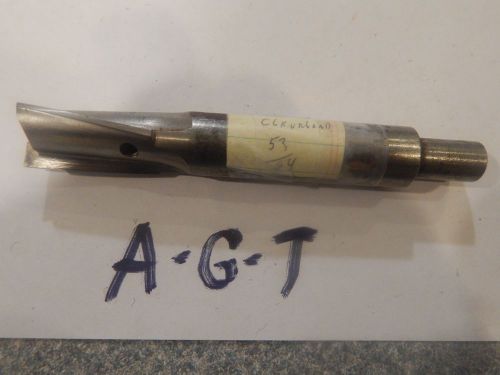

"Cleveland" 53/64" Counterbore ( missing Set Screw and Center Guide Pilot)

"Cleveland" 1" Counterbore (Missing Center Guide Pilot)

Roper Whitney NO 6 Hand Punch Only No Dies Hand Tool USA 590000051 Machine

Shell Reamer Arbor 3/4" Shaft size

Straight Flute Shell Reamer 1-3/4"

Vermont American NEW 31321 bandsaw blade 93"x1/8 tpi 15(NIB)

3 1/2" x 5/8" x 1" HSS Staggered 18 tooth Slitting Saw New

HOUGEN 17224 3/4 INCH x 1 INCH ROTALOC ANNUAL CUTTER NEW FREE SHIP IN USA

HOUGEN 12260 1-7/8" X 2" ROTABROACH ANNUAL CUTTER USED FREE SHIP IN USA

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies