US $43.90

Directions

Similar products from Light Diods & Lamps

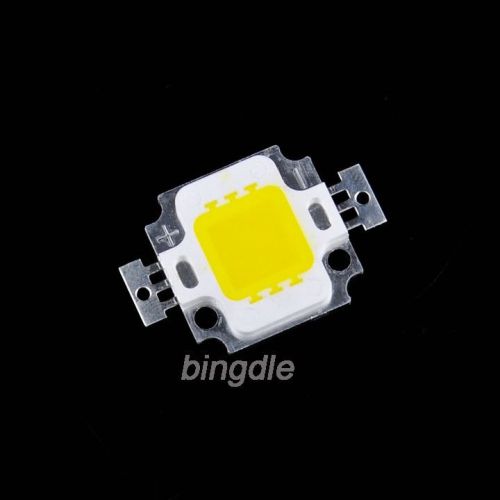

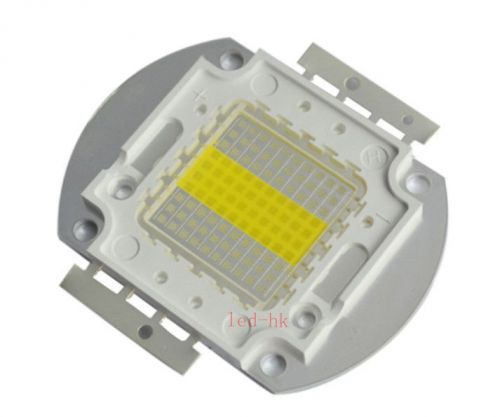

Cold/Pure White qf 100W High Power 9000-10000LM LED light Lamp SMD Chip DC 32-34

9000-10000LM DC 32-34V 100W High Power LED light Lamp SMD Bulb Chip Warm White a

Cold/Pure White DIY High Power jh 900-1000LM LED light Lamp SMD Chip DC 32-34V 1

4500-5600LM High Power LED Lamp light SMD Chip DC 32 -34V Cold/Pure White 50W w

20PCS 5050 3 Chips PLCC-6 SMD SMT Warm White LED 14lm

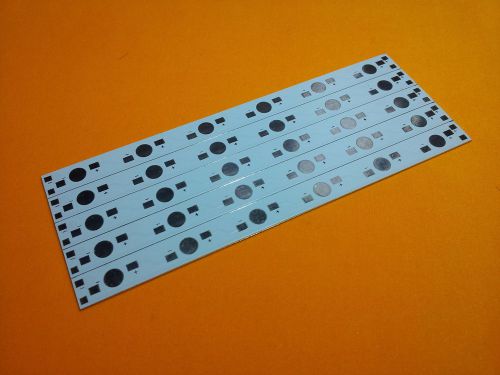

10PCS x 15CM Aluminium PCB Circuit Board for 6 x 1w,3w,5w LED in Series

250 X 10mm 4pin Tri-color Diffused RGB Common Anode Manual Control LED

2pcs 10W UV LED high power led lamp light 395-405nm 90Lm purple 900mA 11-13.8V F

5 pcs 11W 300mA Warm White Round COB SMD LED Light 22pcs Clips

MR11 1W True White LED Quartz Bulb

20pcs male Plug DC 5.5x2.1 Cable connector for led strip light 3528 5050 white

40Watts High Power LED Driver Boost / Step up Topology

2 Pieces Blue LED Power Indicator Signal Light 22mm Diameter Head IP65 110VAC

20P 0.5W HP 8mm White StrawHat LED 140.000mcd 140°

30 Pieces, HLMPM201 Standard LEDs Through Hole 4mm Flat Top Red , NOS

XITANIUM LED-INTA-0024V-41-F-O LED ELECTRONIC DRIVER

3W Pure White COB High Power LED Roundness LED Light Emitting Diode LED new

lots of 10 LED 20W 30V~35V High Power Bright White LED SMD1900~2100LM #02990

4pcs 100W Actinic Royal Blue Hybrid Led Saving 100Watt Lamp Bulb for Aquarium

People who viewed this item also vieved

25 Honeywell OPTO 855-8600-003 photo IC sensor diode schmidt output

9x15cm 1.6mm 1.27mm Double Side Universal Board PCB DIY Prototype Paper PCB

TRF3750T-1900EVM Texas Instruments Evaluation Module

Simco IO Clean 4102098 Anti-Static Neutralizing Air Station

HP Manual 8449A & 8449B PREAMPLIFIERS

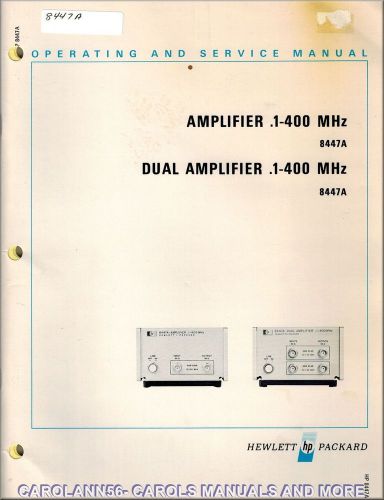

HP Manual 8447A AMPLIFIER DUAL AMPLIFIER

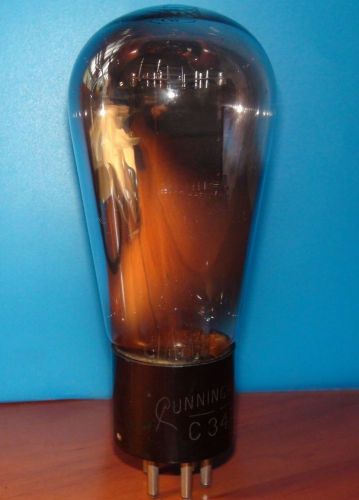

Engraved Cunningham #C-347 Vacuum Tube Results =70

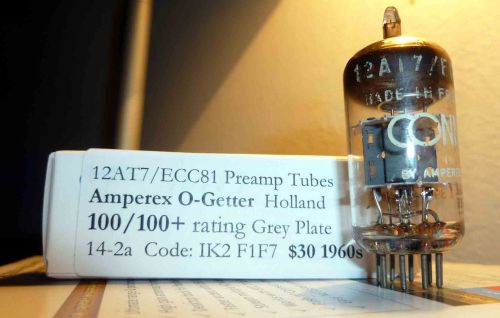

Single Amperex 12at7 Short Grey Plate 100/100

Lot of six new capacitors SPRAGUE 100-160uF - 200VDC. Model TVLU 1230.

10pcs Panasonic FC 470mfd 35v 470uf 10x20mm audio electrolytic capacitor 105C

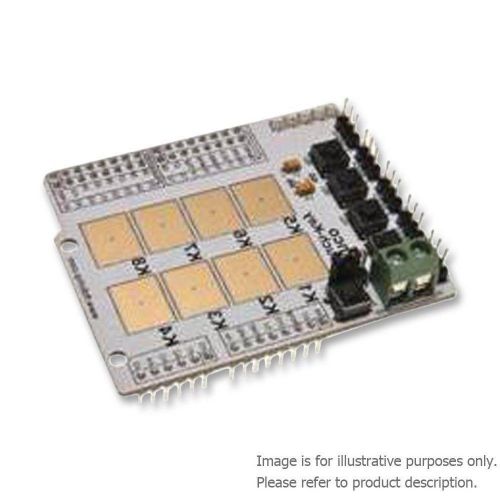

FTDI VINCO-TOUCH TOUCH-KEY SHIELD, STMPE821, VINCO DEV

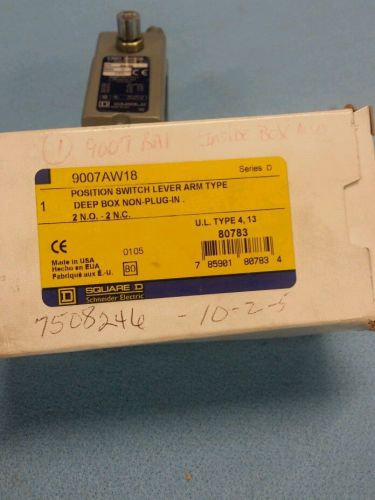

Square D Position Switch Lever Arm Type Deep Box non plug in 9001AW18 series D

DC DC Converter Module 12V To 5V 3A 15W Duble USB Output Power Adapter LX

Waterproof DC/DC Voltage Converter Regulator 24V Step Down to 12V 5A Adaptor LX

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies