US $520

Directions

Similar products from Carbide Inserts & Face Mills

Allied Machine and Engineering #483H-0113 GEN2 T-A HSSCo Spade Drill Inserts

Swarf SNMG 643-R 6620 Carbide Turning Inserts

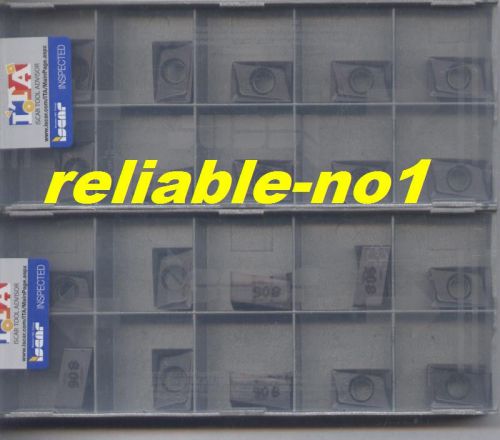

* 30pcs * FREE SHIPPING * ISCAR DCMT 11T308-SM IC 907 30pcs

SECO-02671 TPMT 32.52-F1 GR TP200 10PCS

CARBIDE MILLING INSERTS CDE323R04 cde inserts qty 130

Valenite SNMG432LC SNMG120408LC 929 Indexable Carbide Turning Inserts

* 30pcs * FREE SHIPPING * ISCAR- H490 ANKX 170608PNTR IC 908 30pcs

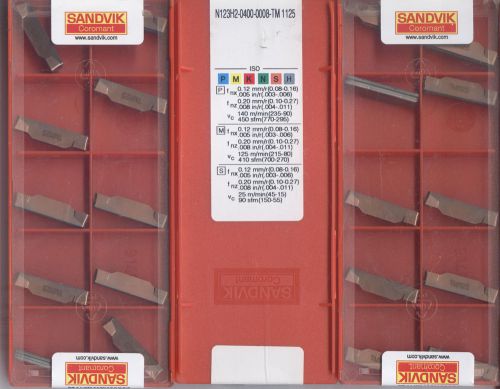

* FREE SHIPPING * SANDVIK N123H2-0400-0008-TM 1125 10pcs * LOT OF *

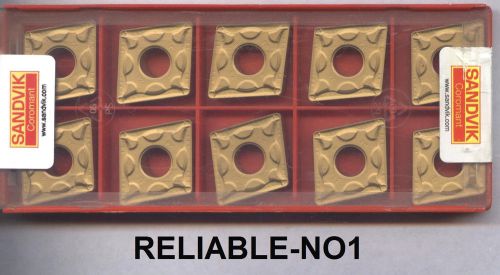

* SHIPPING IS FREE * SANDVIK CNMG 190612-PM ( CNMG 643-PM) 4025 10pcs

Valenite #04053 SNMG322LF SNMG090308-LF SV310 Indexable Carbide Turning Inserts

Valenite SEC422 2G VC728 Polycrstalline Diamond Insert

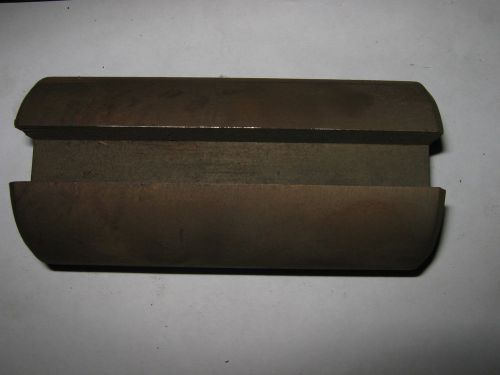

NEW DICO PCD POLY-CRYSTALLINE DIAMOND TIP CARBIDE INSERT SZ-92R6D LOT C10165

Kennametal KSEM replaceable carbide drill tip KSEM2277HPLM, NEW

10 SECO TNMA220416, TK1001 TNMA434 inserts NEW

Walter Valenite 5277415 P28469-6 WSP45 Inserts

ISCAR GIF 4.00E-0.20 IC 8250 10pcs --- GROOVING & PROFILING---

*** ( 10pcs) SANDVIK R390-17 04 08M-PL 1030 Insert ***

SECO CNMG 190612-M5 Carbide Inserts CNMG 643-M5 TP100

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type E, 3" x 6", Uncollared, Used

Keyway Broach Bushing Guide, Type E, 3" x 5 1/4", Uncollared, Used

WNGX453T0820 KY3500 KENNAMETAL CERAMIC TURNING INSERTS

CNGXT0825 KY1310 KENNAMETAL CERAMIC TURNING INSERTS

Lot 1pcs 2Flute HSS-AL Ballnose End Mills R4 Cutting Dia 8mm Length 95mm

Napoleon 8mm water slot cutter straight cutting edge elumatec, Federhenn, Rotox

Machinists 12/17FP BUY NOW Machinists NEW HS 7/16" Socket Head Countersink

Machinists 12/17FP BUY NOW Machinists NEW HS 1/2" Socket Head Countersink

3/8 in 9.5 mm BIG STEEL STAMPS LETTERS ALPHABET by YOUNG BROS. STAMPS *C

1/8 in 3.2 mm LETTERS & NUMBERS FIGURES by YOUNG BROS. STEEL STAMPS *C

Two Yankee Made in USA .2825 High Speed Steel Decimal Reamer 72028251 (B5046)

One MA Ford 0.306 Carbide TrueSize® Reamer 27230600 (B5032)

WIDDER 22260 High Speed Steel Power Hack Saw Blades 12" x 3/32"- 16 TPI-USA-NEW

EISELE CARBIDE TIPPED SAW BLADE 350mm Dia. x 3.0mm x 40mm Hole Dia.

BRAND NEW METAL-PRO GALVANIZED PAINT MARERS IN YELLOW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies