US $108.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Manufacturer | HP |

| Brand | HYPO | ||

| Country/Region of Manufacture | China | ||

| Model | 7 10 12 16 20 MM |

Directions

Similar products from Drilling Heads & Tool Holders

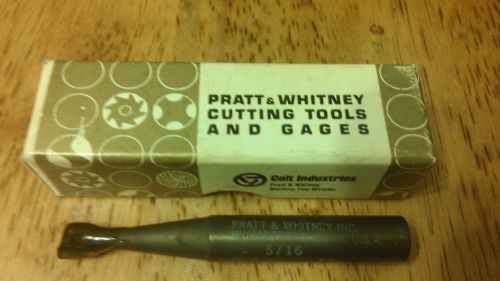

Pratt & Whitney BORING BIT-TOOL/ 3/8 x 3/4 / New in Box LATHE,MACHINIST MILL

Pratt & Whitney BORING TOOL/ 3/4" X 3/4" /NEW OLD STOCK/LATHE,MACHINIST,MILL

Pratt & Whitney BORING BIT/ 1 1/4" X 3/4" NEW OLD STOCK/LATHE,MACHINIST MILL

Pratt & Whitney BORING BIT-TOOL/ 7/16/ New in Box LATHE,MACHINIST MILL

Pratt & Whitney BORING BIT-TOOL/ 5/16---New in Box LATHE,MACHINIST MILL

Pratt & Whitney BORING BIT-TOOL/ 1 / 2 ---New in Box LATHE,MACHINIST MILL

Pratt & Whitney BORING BIT-TOOL/ 9/16---New in Box LATHE,MACHINIST MILL

Pratt & Whitney BORING BIT/ 1"X3/4"-1216-745/NEW OLD STOCK/LATHE,MACHINIST MILL

Sandvik C6-570-3C40198 Dampened Boring Bar

S20R-SCKCR09 20x200L INTERNAL TURNING TOOL INDEXABLE BORING BAR FOR CCMT INSERT

Carboloy MCLNR-24-6D Tool Holder 1-1/2" Square Shank

18MM INDEXABLE BORING BAR - 120L - START BORE 16MM + 10PCS INSERTS MILLING #L118

12MM INDEXABLE BORING BAR - 90L- START BORE 14.5MM - FOR 50MM HEAD -MILLING #L92

18MM INDEXABLE BORING BAR - 80L - START BORE 12MM - FOR 75MM HEAD -MILLING #L108

18MM INDEXABLE BORING BAR - 115L - START BORE 25MM +10PCS INSERTS -MILLING #L117

18MM BORING BAR WITH HSS TOOL BIT -120L -FOR 75MM BORING HEAD -MILLING #L113

1PC. 12MM SHORT INDEXABLE BORING BAR WITH 10PC MITSUBISHI INSERTS CNC MILL #L100

18MM INDEXABLE BORING BAR - 140L - START BORE 16MM + 10PCS INSERTS MILLING #L119

12MM BORING BAR W. HSS BIT- 95L - START BORE 18.5MM -FOR 50MM HEAD -MILLING #L93

18MM INDEXABLE BORING BAR - 80L - START BORE 16MM + 10PCS INSERTS -MILLING #L116

People who viewed this item also vieved

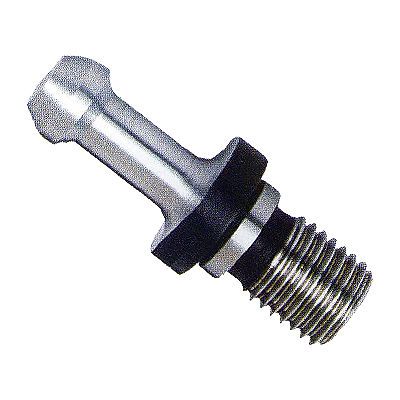

2.360 INCH X 60 DEGREE BT40 RETENTION KNOB (3900-5393)

Techniks SYIC-22917, CAT40XSLN1/2"-3.00", CAT Side Lock End Mill Holder

New ISCAR MM S-A-L5, 50-C, 50-T08-M-C Carbide Stepped Shank New (B16)

New KOMET SWGCR6-01 Turning Toolholder MADE IN USA New (B16)

Jacobs Chuck Key Model K0 1/8" Pilot Jacobs Original

1.75" Straight Shank with No. 4 Jacobs Taper Jacobs Original

NEW Bridgeport 390-DC-4" Zinc Die Cast Insulated Grounding Bushing

EA CNC LATHE TOOL HOLDER BUSHING 1-1/4" 68-15C ( 2 of 2 )

NMTB40 5/8" DIA ENDMILL HOLDER GREAT CONDITION NMTB 40 END MILL LOT C11477

NMTB40 3/4" DIA ENDMILL HOLDER NMTB 40 END MILL LOT C11835

Kennametal KM40 520 CSCLPL09 - KM40 MWL NR08- 1575927R0D

LYNDEX BT 40 1-1/4" END MILL TOOL HOLDER

Morse Taper Extension Sockets JACOBS No. XT22 / 2 MT Hole / 2 MT Shank

Morse Taper Extension Sockets JACOBS No. XT12 / 1 MT Hole / 2 MT Shank

TG100 NMTB 30 QC QUICK CHANGE COLLET CHUCK W/ FOUR TG 100 COLLETS QC30 #C13968

KWIK SWITCH 200 3/8" DIAMETER ENDMILL HOLDER END MILL MORE LISTED LOT C14047

Sunnen Hone Mandrel 2G P28 1625WD 2H (LOC1926A)

Sunnen Hone Mandrel 3G P20 750UA 0D (LOC1926B)

Motor Arbor Attachment 5/8" shaft 1/2" thread RH

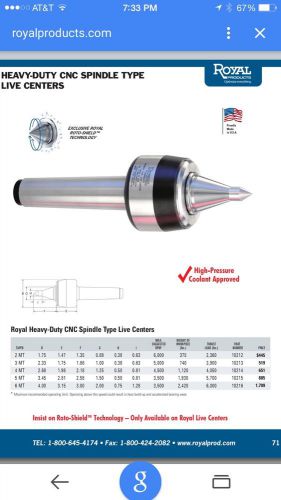

Royal Products Spindle Type Live Center

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies