US $63

Directions

Similar products from Carbide Inserts & Face Mills

10 NEW INGERSOLL PCXF 12-05 J05 CARBIDE INSERTS. GRADE: IN1030 {Y545}

20 NEW INGERSOLL SNGU 1205ENN CARBIDE INSERTS. GRADE: IN2530 {D408}

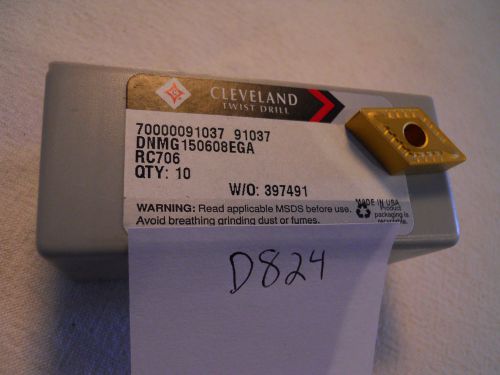

10 NEW RTW DNMG 442E-GA CARBIDE INSERTS. GRADE: RC706 {D824}

10 NEW VERSA-TURN CNMG 432-XE CARBIDE INSERTS. GRADE: LP151. {D136}

10 NEW VERSA-TURN CNMG 432-WM CARBIDE INSERTS. GRADE: LP2002. {D134}

10 NEW TUNGALOY DNMG 432 TN 32 CARBIDE INSERTS. GRADE: T822 COATED {A239}

10 NEW MITSUBISHI SEEN 53EFER1 CARBIDE INSERTS. GRADE: UTi20T {E660}

10 NEW KENNAMETAL CNMG 432A-4T CARBIDE INSERTS. GRADE: NL400 {G315}

8 NEW SUMITOMO CNMG 432 EEX CARBIDE INSERTS. GRADE: EH520 (G415)

10 NEW SANDVIK N151.2-A142-30-4G CARBIDE INSERTS. GRADE: H13A. {C951}

10 NEW SCANDINAVIAN 12X A60 QUAD THREADING CARBIDE INSERTS. GRADE: K20C. {J142}

10 NEW SECO APFT 160430R-75 CARBIDE INSERTS. GRADE: S25M {D206}

3 NEW SECO TNMG 666 MR4 CARBIDE INSERTS. GRADE: 883 {D227}

10 NEW CERATIP CNMG 432 XS CARBIDE INSERTS. GRADE: CR7015 KYOCERA {G306}

7 NEW KENNAMETAL DNMG 432 CARBIDE INSERTS. GRADE: KC935 {H541}

10 NEW KENNAMETAL MANCHESTER GS094R12 / 507-151-36 SEPARATOR CARBIDE INSERT G572

10 NEW K02 381204 KOMET CARBIDE INSERTS. W29 24010.0464 GR: BK4 USA MADE {D927}

ISCAR INSERT GFN 3 IC354 10pcs

ISCAR INSERT GTN 3 IC354 10pcs

DCM 0433 346 063A-8D ISCAR INDEXABLE DRILL BODY NEW TOOL

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type C, 11/16" x 2", Uncollared, Used

Keyway Broach Bushing Guide, Type C, 11/16" x 1 7/8", Collared, Used

KORLOY SP200 - R NC3030 Carbide Inserts NEW

GREENLEAF CERAMIC INSERTS BN-300-831

5/16 Solid Carbide Endmill | TiAin Coated | 4 flute Center Cutting CNC

50 PCS 3/16 .187 Carbide endmill | TiAin Coated | 4 flute Center Cutting CNC

Stainless Wire Knot Cup 2.5" x 5/8"-11

Import Carbon HEX Die, M33 x 1.5mm

NICE LOT OF 12 HSS GUN REAMERS AND COUNTERBORES 37/64" TO 43/64" SHANK CLEVELAND

NICE LOT OF 10 HSS GUN REAMERS AND COUNTERBORES 1/4" TO 1/2" SHANK CLEVELAND

Lot 1pcs TCT Carbide Hole Saw Dia 28mm Tungsten Cutting Hole Saw

NOGA Metalworking Tool NG8000 N Economy Set Handle Deburring Tool+10pcs Blades

HOUGEN COOPERHEAD 18222 11/16" X 2" ANNULAR CUTTER NEW FREE SHIP IN USA

ICS AC2D112 1-3/16 INCH X 2 INCH ANNULAR CUTTER BIT NEW FREE SHIP IN USA

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies