US $3800

Directions

Similar products from Grinders - Professional

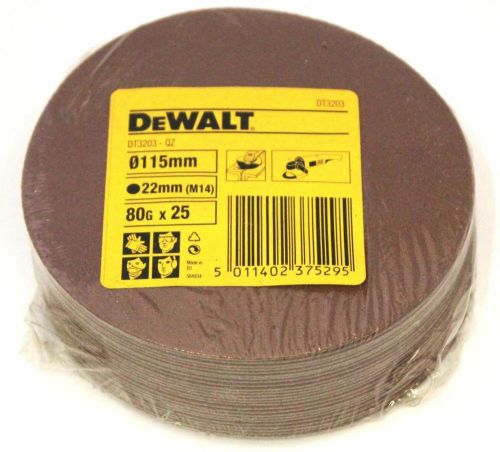

DEWALT DT3213 125MM (M14) FIBRE SANDING DISCS 80G x25

20 BOSCH FIBRE SANDING DISCS 100MM 4" 120G - GERMANY

GENUINE BOSCH SDS CLIC QUICK CHANGE LOCKING NUT M14 GRINDER 1603340031

25 DEWALT DT3222 178MMM FIBRE SANDING DISCS 60G 180MM

2 BLACK & DECKER A1421 HIGH PERFORMANCE TUNGSTEN CARBIDE FINE SANDING DISCS

2 BLACK & DECKER A1423 HIGH PERFORMANCE TUNGSTEN CARBIDE COARSE SANDING DISCS

180MM BACKING PAD & NUT FOR 180MM 7" M14 ANGLE GRINDER SANDER

ELU E37147 125MM x 20MM x 20MM SILICONE CARBIDE BENCH GRINDING WHEEL 60G DEWALT

BOSCH 9" 230MM PROFESSIONAL UNIVERSAL DIAMOND CUTTING DISC 2608602195

Dewalt DW887 1 1/2"(38mm) Die Grinder

Metabo Angle Grinder PA6-GF35 120V

Dynabrade grinder 3" .5hp gearless BASF PPG SATA IWATA

EZ Plug Holder 5/8"-11 Tool to 2" Plus Holder EZPLUG Adapter

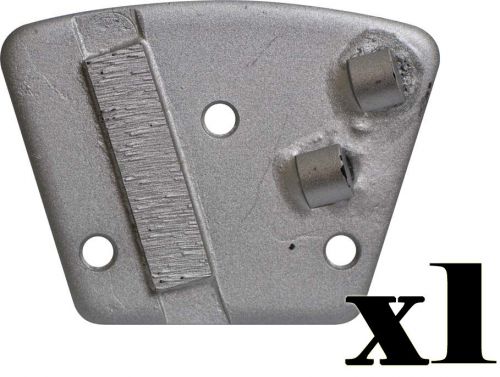

PCD Scraper Floor Coatings Remover Thick Paint Epoxy Mastics (Counter Clockwise)

NEW MILWAUKEE ARMOR CUP 5" MASONARY GRINDING WHEEL 5/8"-11 THREADED HUB 16/24 GR

115mm 4 1/2" Angle Grinder Pin Spanner - 30mm Centres

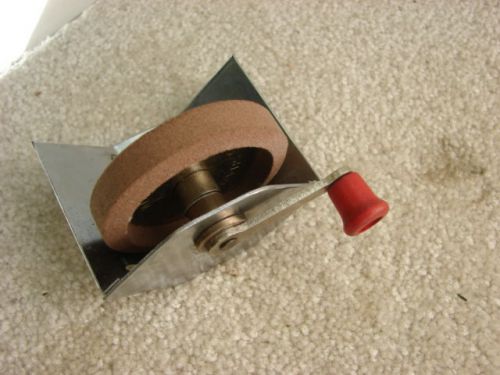

Vintage Hone-Rite Knife Sharpener Hand Turn Wulff

econ-o-line Accro angle tangent to radius dresser fits serface grinder grinder

100mm 4" Twist Knot Wire Wheel Brush For 115mm Angle Grinder Metal Work M14

People who viewed this item also vieved

DAYTON 1 TON 3YB83H CHAIN HOIST EQUIPMENT LIFT SINGLE PHASE 115V

SIEMENS 5SH112 - PACK OF 50 - DIAZED FUZE CAP D2 FUSES VERAMIC 25 A, NEW

Offset Star Key Set - 9 Pc on Storage Holder - Tamperproof

New Milwaukee Power-Plus Battery Adapter 48-03-2600

Vertical Concrete Brittle Shale 9" Texture Roller

–40 KW 2002 Kohler Generator set, Only 848 Hours! John Deere Engine, Serviced...

Genuine Wacker Part WACKER NEUSON PARTS # 0108115 CABLE-SET

PRIME INDUSTRIAL GENERATOR 5 W ADAPTER CORD-20 AMP- NWT

Hilti empty case and instruction manual for TE 1000-AVR jack hammer New

Wagner 0283022 HT775 Heat Gun Heavy-Duty Industial

800A By-Pass Isolation Automatic Transfer Switch

Georges Renault, ERA15J, R/A Nutrunner 15NM, Chicago Pneumatic, 6151651910, NOS

GENUINE Bosch 11304 Guide Tube PART # 1 615 806 029

Champion 120 gallon compressor

KUSHLAND CONCRETE MIXER 1.5 TO 2 CUBIC FEET CONCRETE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies