US $59,000.00

Directions

Similar products from Lab Fermenting Equipment

Wave Biotech Stainless Steel Tray (20L Holder)

All American Autoclaves Portable Electric Steroclave 25X

New Brunswick Bioflo IV 20L Fermentor

MUELLER 50 LITER JACKETED BIO-REACTOR STAINLESS STEEL TANK W/ TOP MIXER, 45 PSI

PRECISION 200 LITER BIO-REACTOR 316 STAINLESS STEEL JACKETED PRESSURE VESSEL

DCI 400 Liter Jacketed Bio-Reactor, Stainless Steel Tank w/ 40 PSI Max Pressure

LEE / Sartorius Stainless Steel Jacketed Vacuum Vessel 150 Liter w/ Mixer 50 PSI

PRECISION 100 LITER JACKETED BIO-REACTOR 316 STAINLESS STEEL 40 PSI PRESSURE

NEW BRUNSWICK CELLIGEN PLUS BATCH CONTINUOUS CELL CULTURE M1228 - 1001

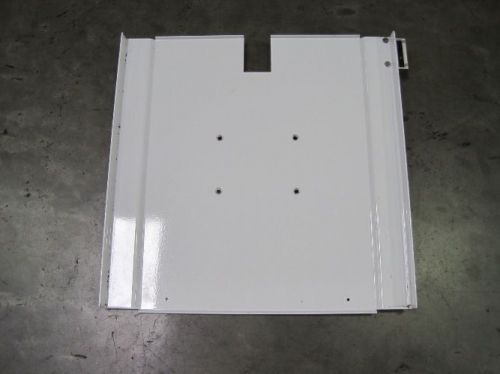

R110130 Wave Biotech Reactor Platform w/ Bag Detector

R110132 Wave Biotech Reactor Platform Without Bag Detector

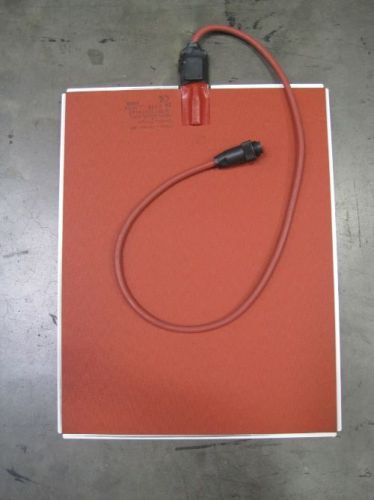

R110135 Wave Biotech GE Bioreactor Heater Pad 20

NEW BRUNSWICK SCIENTIFIC BIOFLO 3000 BATCH CONTINUOUS BIOREACTOR FERMENTOR

100 Liter Stainless Steel Tank Keg Pressure Vessel Fermenter Brewery Winery Beer

100 Liter Keg Pressure Vessel Stainless Steel Fermenter Brewery Winery Beer Tank

50 Liter Keg Stainless Steel Fermenter Brewery Winery Beer Tank Pressure Vessel

New Brunswick Celligen Plus Batch Continuous Cell Culture & Nalgene Buckets

Sartorius 15 L Bioreactor Vessel C10-3

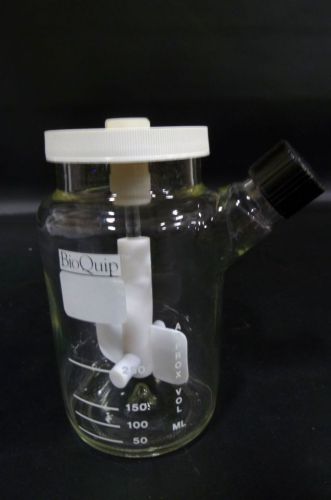

BioQuip Spinner Flask Bioreactors 250ml Lab Glassware Single Sidearm

People who viewed this item also vieved

New Focus (Newport) 9801 Mirror Mount

NIKON MSK00401 CF E PLAN ACHRO 40X MICROSCOPE OBJECTIVE NEW

MKS 1179A mass flow controller mfc 3 slm H2

LEYBOLD 287-02-V2 right angle Valve #3

Extech SD200 3-Channel Temperature Datalogger Type K Thermocouple W/AC Adapter

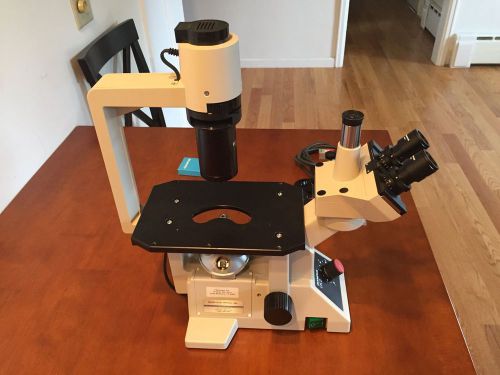

Olympus CK2 Inverted Microscope & EXTRA STUFF

NICE GCA PRECISION SCIENTIFIC VAC TORR - SMALL VACUUM PUMP - VAC TORR 20

Newport Motorized Heavy-Duty Linear Stage ESP Compatible M-TSP100 X-Axi

SmithKlein Branson Bransonic 12 Ultrasonic Cleaner Model B-12 Tested

IKA Ultra-Turrax Tube Drive Control Dispersing, Stirring & Grinding Work Station

Fisher Scientific Isotemp Model 170 Incubator Oven lab-line boekel vwr thermo

Mixer stirrer impeller 6" diameter , 3 blade prop type

Tissue-Tek Accu-Edge Universal Cryostat Blade System 4681 Microtome

Buchi Rotavapor Glass Lot in perfect condition .

SciCan Statim Autoclave Sterilizer 2000 5000 CONDENSATION COIL Condenser Waste

Olympus Microscope Illuminator Power Supply Model TF 6V 5A Tested

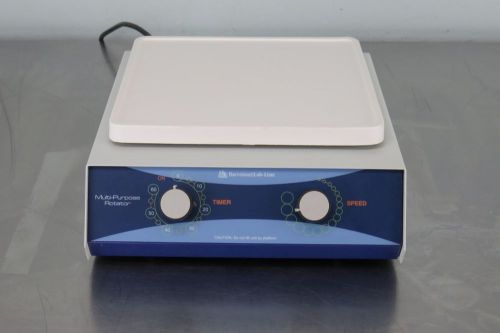

Thermo Labline 2309 Rotator Tested with Warranty Video in Description

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies