US $890

Directions

Similar products from Other Printing & Graphic Expendables

Lates 2016 AcroRIP_V8.2.6 DTG / FLATBED / Printer Rip Software WITH DONGLE

NEW BLUFFTON 3/4 MOTOR 1303022111 CZ2

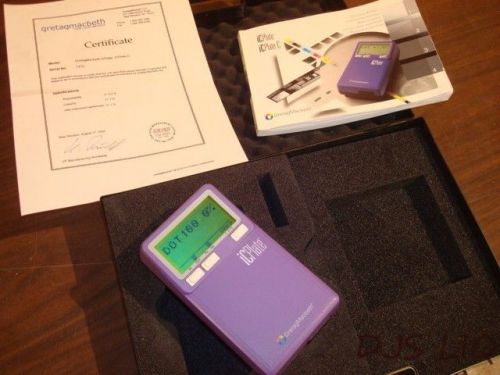

GRETAGMACBETH iC PLATE PLATE C READER CZ1

Heidelberg Printing Press T Shirt XXL

Heidelberg Printing Press T Shirt 3XL

Heidelberg Speedmaster Printing Press T Shirt XL

Heidelberg Printing Press T Shirt Lrg.

Pleiger PT22 70 Duro 3/8"x2"x18" Screen printing Squeegee Blade

Pleiger PT22 60 Duro 3/8"x2"x18" Screen printing Squeegee Blade

Prism Attachment for Hellige Pocket Comparator 600-PA

Vintage 7 Water Glasses - 1960s Printing Press Paper Publishing Business UNIQUE

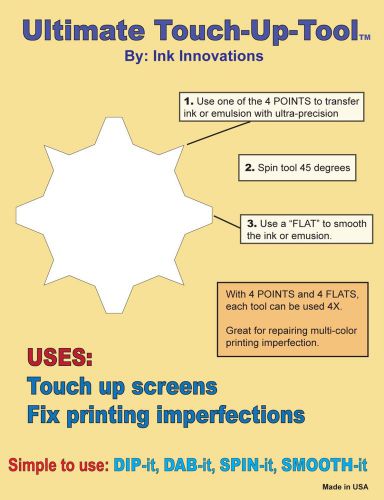

50 Ultimate Touch-Up-Tools by Ink Innovations makers of Ultimate Clean Up Card

NEW++RATED 3D Former Printing Pen 2016

PANTONE Chips Coated & Uncoated Supplement. Shows the 112 new colours.

Gaebel 12" Flexible Stainless Steel Rule Gague (Inch, 6,8,10,12 Point) No. 612-A

QTECH XRES DIGITAL COUNTING SCALE 3 LB

Short-Distance 1.75mm 0.5mm Nozzle J-head Extruder Kit Professional for 3D Print

Short-Distance 3mm 0.3mm Nozzle J-head Extruder Kit Professional for 3D Printer

MICROPERF 30 TOOTH OFFSET PERFORATING RULE - BOYD LOW COST ALTERNATIVE! 20' ROLL

NEW IDS IDS160 ROLL TAPE PRINTER 115V-AC D522984

People who viewed this item also vieved

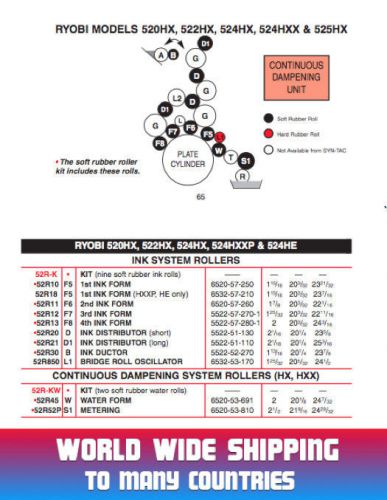

52R-K RYOBI 520 HX, 522HX, 524HX, 524HXXP, 524HE, & 524GX 9 ROLL KIT

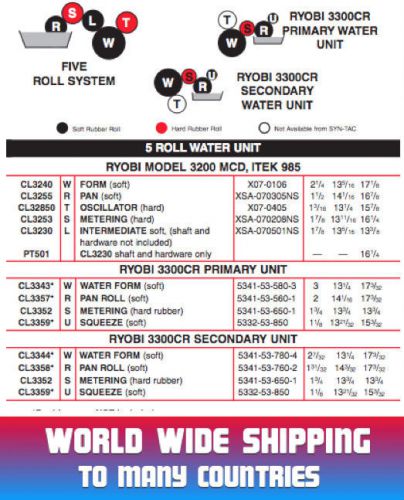

CL3358 RYOBI 3300CR & A B DICK 9980 SECONDARY ROLLER UNIT PAN ROLLER (SOFT) QTY1

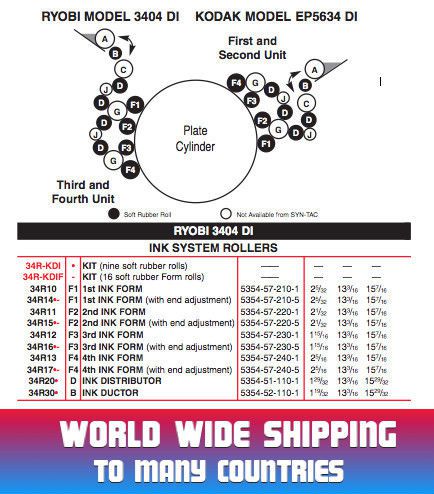

34R-KDI RYOBI 3404 DI 9 ROLL KIT

Roland Circuit/Transistor A1746 * 6 pcs wholesale

Compatible Roland Wire for Roland FJ-540/FJ-545EX/SJ-540/SJ-545EX

OEM Belt for Roland XJ-540/XC-540/SC-540 —— 5.5m/pc

Democratic Party Advertising~People's Union~ Printer's Letterpress Type Block

MOPAR logo CNC Plasma .dxf clip art

Maltese Cross CNC ready .dxf format clipt art. Iron Cross. Various designs.

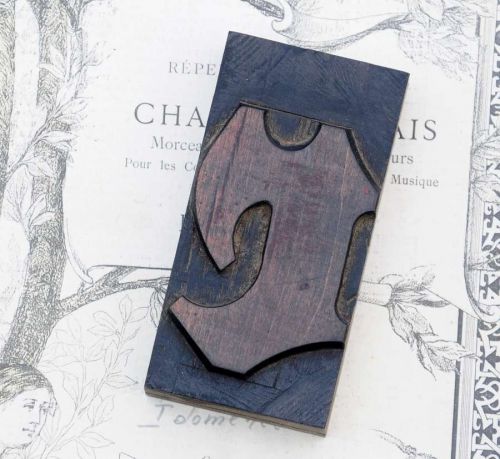

letter: r blackletter wood type 3.54" woodtype font letterpress printing block

Collage "KISS" made of letterpress wood type characters in old drawer design

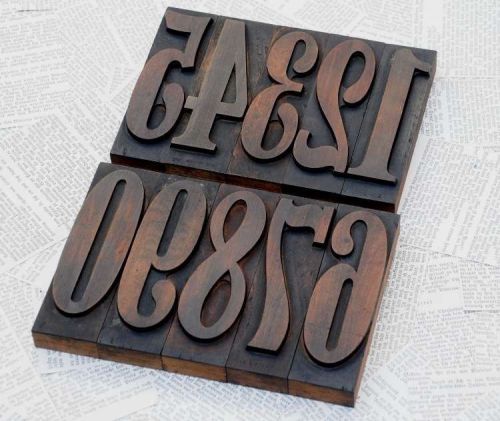

0-9 numbers letterpress wood printing blocks type woodtype wooden block Vintage

X-Rite Model DTP32HS Spectrophotometer

X-Rite Model DTP41B Spectrophotometer

X-Rite 331 Battery Operated B/W Transmission Densitomter

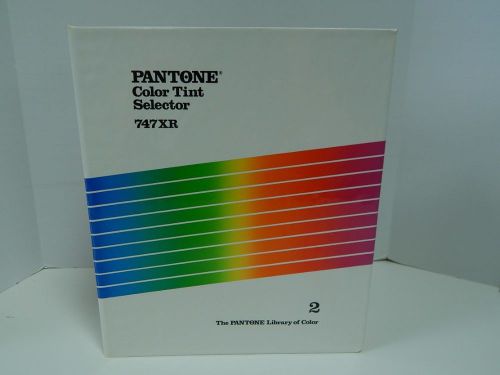

Pantone Color Tint Selector Pantone Library of Color 2 Ring Binder Excellent

Vintage IPI Color Finder w/Instructions and Original Box

Pantone Wedding 2010 Color Guide 190 Colors

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies