US $130

Directions

Similar products from Metals & Fusions

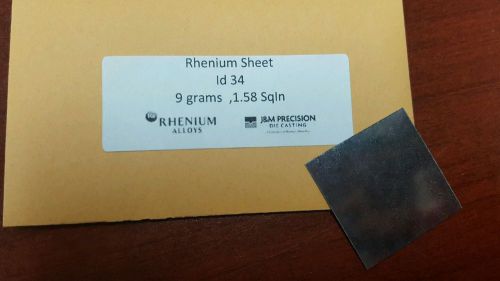

Rhenium sheet id # 34 9 grams 1.58 sqin.

304 STAINLESS STEEL 1.375 OD X 3.5 INCHES LONG

INCONEL 718 1.875 OD X 1.05 LONG

347 SS Stainless Steel 2.5 O.D. 2 1/2 O.D. Priced by the inch 304

Phosphor Bronze 1.57 dia 6.75 long 1 1/2 Brass 1.5

COPPER BAR SQUARE 1.5 X1.350 SOLID 110 COPPER PRICED BY THE INCH 1 1/2 X 1 3/8

BRASS C260 1/8 THICK 10.75 X 7.87 X 13.2 X125 10 GAUGE SHEET PLATE TRIANGLE

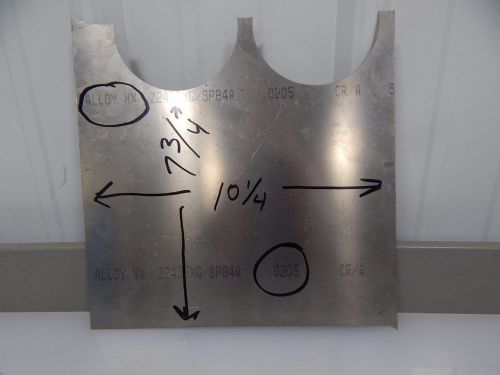

HASTALLOY-X HIGH TEMP SUPER ALLOY SHEET 10.25 X 7.75 X .020 THICK METAL PLATE

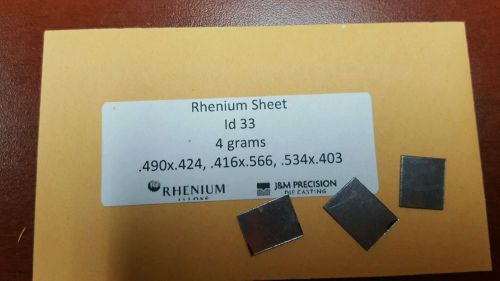

Rhenium sheet id #33 99.99 4 grams

Rhenium sheet id# 32 99.99 high dense annealed sheet

Rhenium metal sheet 4 pcs id#30 4 grams

Solid disc of aluminum metal, 6 inches diameter x 3/4 inches thick, never used

Titanium Plate 6AL4V 44.5" x 9.25" x .153"

Titanium Plate 6AL4V 46.5" x 10" x .153"

Titanium Plate 6AL4V 44.5" x 10.75" x .153"

Titanium Plate 6AL4V 29.25" x 13.25" x .153"

Titanium Plate 6AL4V 29.25" x 13.5" x .150"

Titanium Plate 6AL4V 46.5" x 10.5" x .153"

Titanium Plate 6AL4V 46.25" x 10.25" x .153"

People who viewed this item also vieved

1/2" Double Socket 4 pc TUBOFLEX 225.35bk Flexible Coolant Hose Pipe

Donaldson Torit Dryflo DMC-MMB Dust Collector Air Handler CNC Cutting Grinding

1/2" Double Socket Pack 4 pc TUBOFLEX 225.35 Adjustable Flexible Coolant Pipe

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies