US $3,499.99

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Pall |

| Country of Manufacture | Germany | ||

| Model | FFS02 HAM | ||

| Palltronic Flowstar | 'High Flow' Palltronic Flowstar | ||

| MPN | FFS02 HAM |

Directions

Similar products from Measuring Devices

ISCO UA-5 Lab Absorbance Fluorescence Monitor w/Type 6 Optical Unit PARTS

Pharmacia-LKB - Control & Optical Unit UV-1 Chromatography Single Path

Gilmont Flowmeter Accucal GF-6341-1135 with base F-4001 Lab Bio Chemistry

Roche Cobas Amplicor Sampler Analyzer System

Coulbourn Instruments H24-61 Emitted Infrared Body Heat 8-14um Activity Monitor

Millipore C5510-93 Lab Rapid Microbiology Detection Video Image Processor Unit

Dionex AD20 Absorbance Detector HPLC Lab Chromatography OPTICAL CHASSIS ONLY

Dionex AS50 AutoSelect Autosampler 1-8000uL IC/HPLC Chromatography Lab PARTS #4

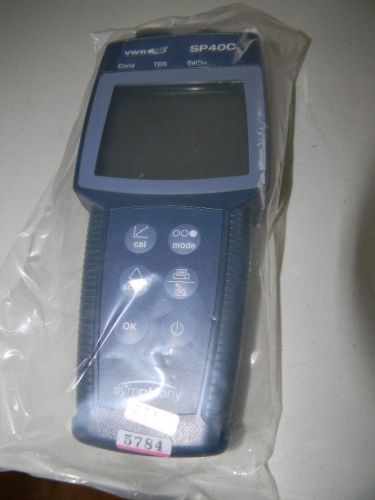

VWR sympHony SP40C Conductivity Meter, No Probe Included

New Brunswick Bio Flo 110 Gas Mix Controller M1273-3104 no Probes or Cables

GE Healthcare WavePod R1113, W pH, Airpump, DO, O2 & CO2 Mix

Dr. Schleuniger Pharmatron MDU-2, Cap Torque Measuring Unit TM-200, Manual

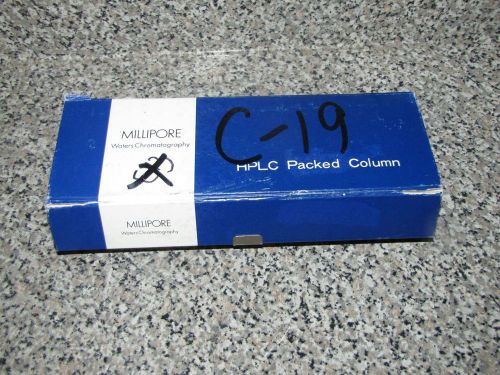

MILLIPORE WATERS DELTA PAK 5U C18 300A 3.9X150MM SILICA ANALYTICAL COLUMN

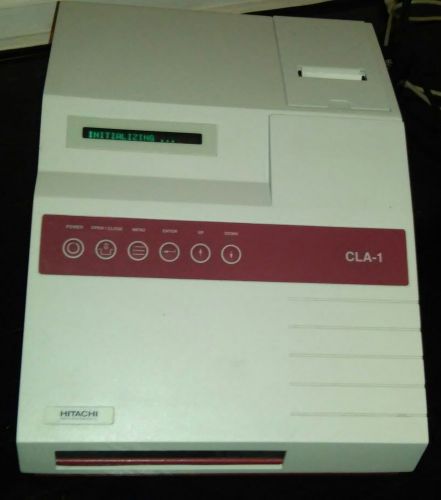

Hitachi CLA-1 Luminometer In Vitro Allergy Diagnostic System

FISHER BIOTECH ELECTROPHORESIS SYSTEMS GEL DRYER TRAP FB-GDT-45 freeze dry pyrex

Fargo HDP825-LC ID Card Thermal Printer Professional Series warranty

Pall Multi-Well Plate Vacuum Manifold

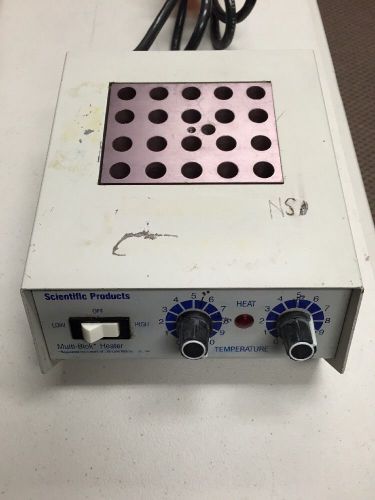

BAXTER SCIENTIFIC PRODUCTS MULTI-BLOCK HEATER H2025-1A

New Digital Conductivity TDS Salinity Meter Tester DDS-307A uzyp

People who viewed this item also vieved

Ritter Midmark M9 M11 Overtemp Thermostat

Fisher Scientific FS60 6 Quart Sonic Cleaner Stainless Ultrasonic Cleaner

Buchi R200 Rotary Evaporator with Vacuum Control

LW Scientific Protein / Specific Gravity Refractometer CTL-REFM-PRSG

++ SPECIAL OPTICS MODEL 50-150-5X-248 LENS / LASER BEAM EXPANDER?

LEITZ ERGOLUX TYPE 020-448-026/572-001 TRINOCULAR HEAD 512 740/20 MICROSCOPE

Spectral Instruments Series 600 Camera Refrigeration Line Heater

5pcs B10 10*5mm magnetic stirrer mixer stir bar PTFE model B Ring

AEROTECH DM4005P-A-40 DYNACRON STEPPING DRIVE DRIVER CONTROLLER

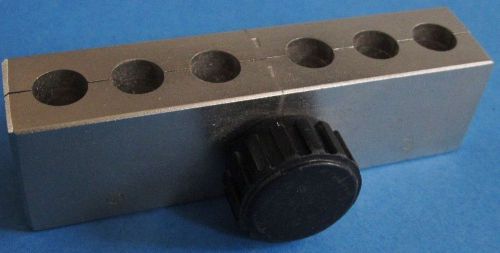

SUPPOSITORY MOULDS LAB EQUIPMENTS INSTRUMENTS PHARMACEUTICAL SUPPOSITORY MOULD 6

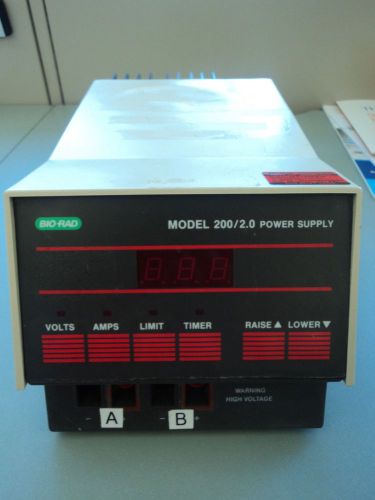

Bio Rad Model 200/2.0 Power Supply

Engel Vacuum/Suction Pump EUS Model 17 U

Chart Paper Roll, Omni Scribe Houston Instrument RCX-103

3073:Tecan:Co2 4 - Slot 37:Incubator Shaker

Fibrinotherm Baxter E- 101844 Warmer Stirrer Device Lab

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies