US $221.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Apollo |

| Model | APPOB30034 |

Directions

Similar products from Tubes

Trap Adapter Ground Joint 1 1/2" Od X 1 1/2" Fip 162075 Poly Tubing and Fittings

Sink Tailpiece PVC 1 1/2" X 12" 172228 National Brand Alternative 172228

P-Trap 1-1/2" PVC With Trap Adapter Bag 0143478 Watts Water Technologies 0143478

Waste Arm Slip Joint ABS 1 1/2" X 15" 88085 National Brand Alternative 88085

P-Trap 1-1/4" PVC Less Adapter Bulk 0141410 Watts Water Technologies 0141410

Sharkbt Slip Cpling 1-1/4"Lf SB0635 CASH ACME Poly Tubing and Fittings SB0635

Pushfit Elbow 1/2X1/2 Lf 272899 National Brand Alternative 272899 076335193861

Trap Conn 1-1/4 Od X 1-1/4 Mip 162060 National Brand Alternative 162060

Double-Flange Sink Tailpiece PVC 1 1/2" X 16" 172230 National Brand Alternative

D/Wshr Tailpc Dc 1-1/2X8X3/4 151021 National Brand Alternative 151021

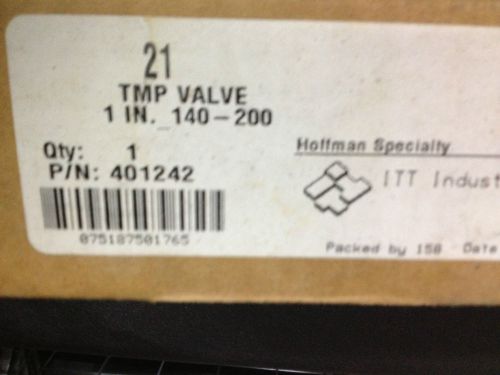

Hoffman 401284 1-inch 21 Tempering Valve 1" (140F - 200F)

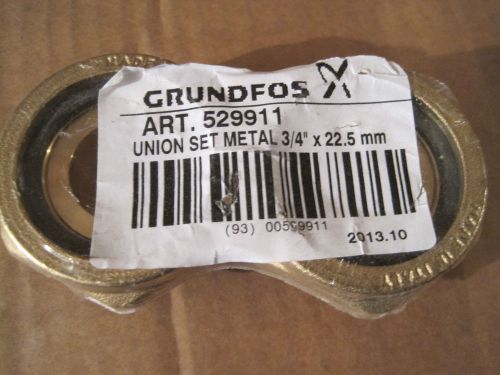

3/4" Sweat Metal Grundfos Pump Union Set 529911

Pex Coil 1/2In X 50Ft White CASH ACME Pex Tubing U860W50 697285260504

SAFGH 06151 SafePEX Tubing, 1/2" X 5' , A-PEX Hot/ Red Writing New

1/4" EG Universal Beam Clamp, Malleable New

WATTS Clear Vinyl Tubing 1-1/4" OD X 1" ID 1/8" thick Tube, SOLD "BY THE FOOT"

Zurn Pex Q4PC100X 3/4-inch x 100-foot White ZurnPex Non-Barrier Tubing Coils

Zurn Pex QB3PC50X 1/2-inch x 50-foot White Zurn Pex Non-Barrier Straight Tubing

Zurn Pex Q3PC100XBLUE 1/2-inch x 100-foot Blue ZurnPex Non-Barrier Tubing Coils

Zurn Pex Q3PC100XRED 1/2-Inch x 100-Foot Non-Barrier Tubing Coils, Red

People who viewed this item also vieved

1 1/2 " DWV Copper And Brass Fittings Lot. Nibco

WATTS WATER PEX ANGLE VALVE WITH WASTE DRAIN.

Brass compression sleeve-1/4" brass comperssion sleeve

Mold 9.2mm Coarse Thread Brass Nipple Pipe Quick Fitting Connector 8" Long

RUB 1" 600 CPW PN40MS58 STAINLESS STEAL

OHIO BRASS GLOBE VALVE T-PATTERN / 2" IN / FNPT / BRONZE / N/S 6200

mifab mhy cia 18 a hydrant repair kit

B&K 3/4" gate valve threaded NEW brass

1-1/2" SPLIT RING HANGER H72150

Lot of W.K. & Sons "79" Plumbing Tags Identifiers Brass Checks Badges Used

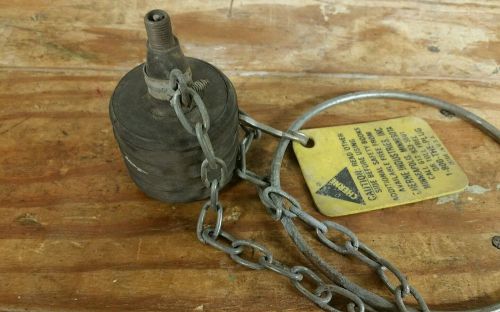

CHERNE 4" TEST BALL, SEWER, 26" LONG, MUNI

CHERNE 2" TEST BALL, SEWER, MUNI, 3" LONG

CHERNE 1-1/4" - 1-1/2" TEST BALL, SEWER, MUNI, 5" LONG

Homewerks VAC-VBK-X1B Vacuum Breaker Replacement Kit for Traditional

LDR 020 6404 4-Inch Frost Proof Sillcock, Chrome Plated

Woodford 10105 Plunger Only For Y34 Hydrant

Woodford Y 34 Yard Hydrant Repair Kit

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies