US $8,500.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | GENIUS |

| Country/Region of Manufacture | India | ||

| Model | GE-60P |

Directions

Similar products from Sealing Machines & Bag Closers

Powerseal 8" IMPULSE SEALER KF-200H -TCI008

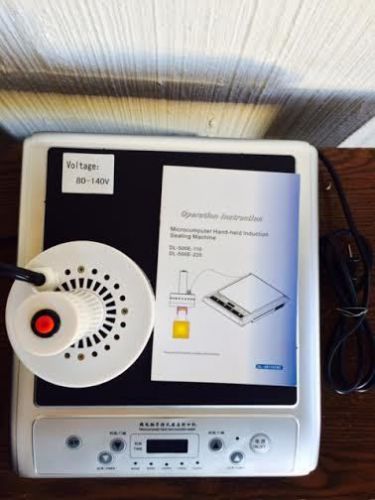

Handheld Induction Sealer Bottle Cap Sealing Machine 1200 W Max. 20-100 mm 110V

Induction Heat Sealer Machine For Bottle Lid Cap Sealing Gasket 110v-Glass & Pet

Multivac Rotary Encoder Kit 19.186.2051.02 - 100373430 for R230 & R530 – NIB

110V Induction sealing machine handheld sealer Aluminum Foil Bottle Lid Cap

8" Hand Impulse Sealer Heat Sealing Machine Plastic Bag Sealer Poly Closer

PVC heat shrinkable plastic bottle cap red wine shrink machine

ALL PACKAGING MACHINERY & SUPPLIES TABLETOP BAGGER - NEW ANDY 3 MODEL

BOPP Polypropylene Resealable Bags 3.5"x4" Closed Size - Pkg 100

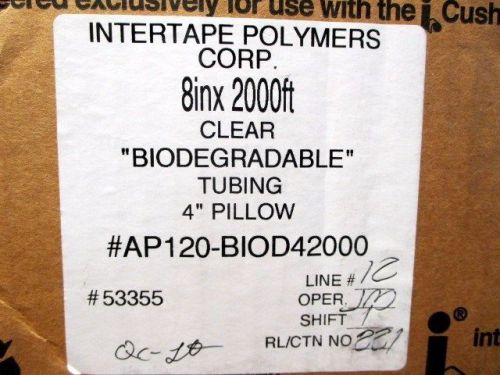

ICUSHION Air Pillows 8" x 2000' Clear Biodegradeable Tubing 4" Pillow

3452 SW W-605A 24” Automatic Single Impulse Sealer

Brand New EntrePack Double Chamber Vacuum Packaging Machine Model D24

Fuji V-402 Series Vacuum Impulse Sealer

NEW* CCC HC 150 Portable Carton Stapler Machine (Carton Closing Corporation)

Super-Sealer Portable Shrink Packaging System Machine Used

110V Electromagnetic Induction Heat Sealer Machine For Bottle Cap Sealing Gasket

16"Table Top Heat Sealer Impulse Bag Sealer- Bag Cutter

Round Wire Conversion KIT for 16" Hand Impulse Heat Plastic Bag Sealer 2 Kits !

3M Matic Case Sealer 700R Type 29200

People who viewed this item also vieved

OWENS-ILLINOIS MODEL 30 CONTINUOUS MOTION ADHESIVE APPLICATOR

OPTICON BARCODE SCANNER LGZ7225 (A40733211) w/ Charger, RS232 Cable, User Manual

Dispensa-Matic U-45 Label Dispenser Fair Condition

Dispensa-Matic U-45 Label Dispenser Good Condition

3/4" Steel Strapping, 0.023" Thickness, Standard Grade, 1700' Roll

Desktop binder Desktop Strapping Machine

HEAVY DUTY YBICO STEEL STRAP TENSIONER

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies