US $299.00

| Condition | Seller refurbished

:

An item that has been restored to working order by the eBay seller or a third party not approved by the manufacturer. This means the item has been inspected, cleaned, and repaired to full working order and is in excellent condition. This item may or may not be in original packaging. See the seller’s listing for full details.

|

| Seller Notes | “MACHINE WAS STEAM CLEANED, FULLY SERVICED,TESTED FULLY, HEATER HAS A NEW ELEMENT,CUTS PERFECT,NON JAMMING, PERFECT MACHINE !! WE HAVE BEEN SERVICING TAPE DISPENSERS AND CUSTOM PRINTING TAPE SINCE 1949 !!!!” |

Directions

Similar products from Tape Dispensing Devices

6 Tape Plastic Dispensers Cutter Packaging Shipping Snap In 2 inch Mini

Tape gun with 2 inch blade and comfort grip

Tape gun with 3 inch blade and comfort grip.

Highland Hand Held tape dispenser

NFL HELMET Tape Dispenser ~ New Tennessee Titans Football Helmet ~ Great Gift

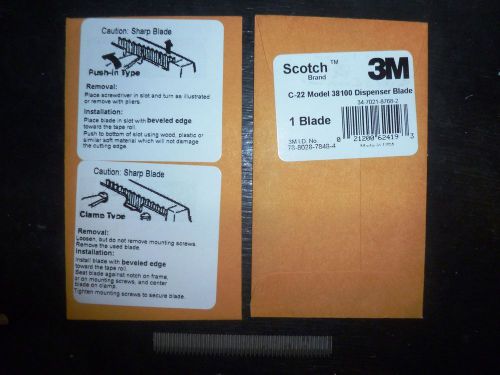

1 Tape Dispenser Blade 3M Scotch C22 Model 38100 @ 2.5" New

MARSH GUMMED TAPE DISPENSER !! MODEL 5HT !! OLDIE BUT GOODIE PLUS FREE TAPE

Scotch Heavy Duty Tape Dispenser Industrial Heavy Metal Base Gold Vintage Single

Electric Automatic Electronic Tape Dispenser

BETTER PACK®TAPE DISPENSER 755 WORKS PERFECT* I JUST INSTALLED A HEATER !!

ULINE 2" Tape Gun Tape Dispenser Heavy Duty Industrial. Used. Clean. With Tape

Better Pack 555 S Electronic Tape Dispenser

Vintage Simplex No.3 Wet Tape Dispenser

MARSH MODEL 5 HT HAND TAPER GUMMED WET PACKING TAPE DISPENSER

NEW Scotch - C38 Desktop Tape Dispenser, 1" Core Free Shipping

Line-Rite Sport Tape Machine New in Box

![Deluxe Boutique Tape Dispenser Clear Rhinestone Holds Total 1 Tape[s] - Refilla](/_content/items/images/47/3686147/001.jpg)

Deluxe Boutique Tape Dispenser Clear Rhinestone Holds Total 1 Tape[s] - Refilla

5 SCOTCH 3M REINFORCED TAPE SHIPPING PACKAGING Box PACKING Tape New

3 SCOTCH 3M High Performance TAPE 2in X 800in Roll SHIPPING PACKAGING PACKING

People who viewed this item also vieved

QTY 2 Boxes SIGNODE 2040 - 2X1458G INDUSTRIAL STRAPPING TENAX DEMO

North Shore Shipping NS-22 Manual Package Bander

Signode 2OR38V 20R38V Pneumatic tension weld banding tool

6 Straps Polypropylene Pre-Cut Strapping White 1/2"x17'

GERRARD & COMPANY PLB-4A PLASTIC BUCKELS 1/2" ( 500 PCS. )

Duck Brand Hello Kitty Licensed Packaging Tape with Dispenser, 1.88-Inch x

Shurtape HP-232 Cold Temperature Performance Packaging Tape: 2 in. x 110 yds.

Packtapes 4-rolls Packing Tape 3"x110 Yds 2.0 Mil - Bopp Material (Tan) - Strong

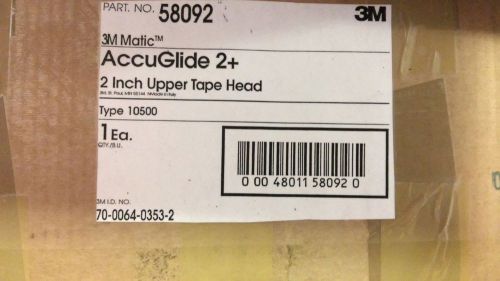

3M AccuGlide 2+ Upper Tape Head, Part # 58092 New!

Duck Brand HP260 High Performance 3.1 Mil Packaging Tap...Free USA Fast Shipping

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies