US $25.50

Directions

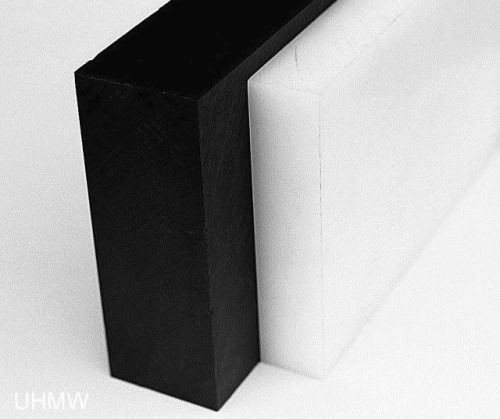

Similar products from UHMW Materials

UHMW virgin white sheet 3.875'' x 5.375'' x 12.5'' Made in USA CNC (9.1M)

UHMW virgin white sheet 4.875'' x 5.125'' x 6.625'' Made in USA CNC (5.8B)

2 Polyester Sheets Mylar Clear/High Gloss Finish, .007" x 31" x 41" 2 Pc HEAVY

Quadrant EPP TIVAR CERAM P UHMW-PE Premium Microsphere Filled, Machinable

UHMW Black Virgin Polyethylene 1.50'' x 8.00'' x 15.50''

UHMW Black Virgin Polyethylene 1.25'' x 7.50'' x 45.50''

UHMW Repro Black Polyethylene 2.00'' x 3.625'' x 19.25''

UHMW SHEET 1/4 " X 12" X 8.50"

UHMW SHEET 1" X 7" X 5.25" TIVAR 1000 Natural Virgin UHMW-PE

NEW Browne Foodservice (PER69) - 6 x 9 High Density Cutting Board

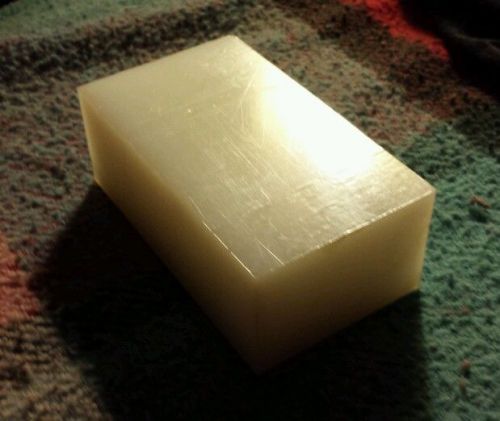

UHMW Plastic White 6-3/4" x 4-1/2" x 2-5/8"

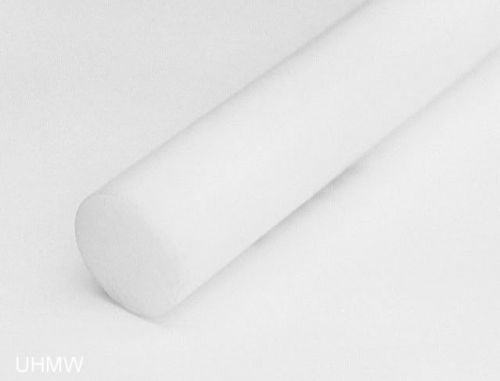

UHMW virgin white rod 9.375'' dia x 5.5'' Made in USA CNC (13.3AM)

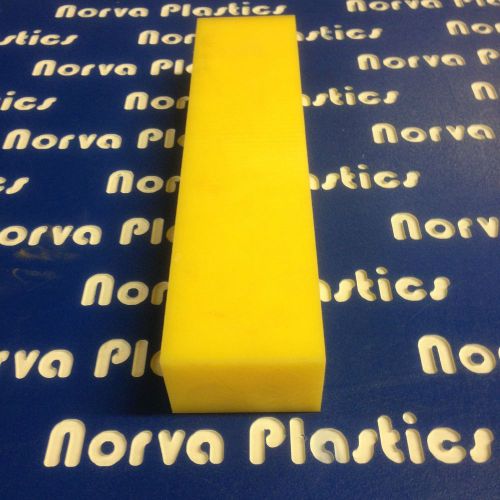

UHMW -Yellow 2" x 3" x 12 1/2"

UHMW Black Virgin Polyethylene 1.75'' thick x 6.50'' x 24.00''

UHMW Black Virgin Polyethylene 2-15/16'' thick x 7.00'' x 24.00''

UHMW Black Virgin Polyethylene 1.75'' x 7.00'' x 20.50''

1pcs UHMW PLASTIC Sheet Plate 1mm * 200mm * 200mm #VB-A

1pcs UHMW PLASTIC Sheet Plate 2mm * 200mm * 200mm #VB-B

UHMW sheet virgin natural 1 1/2" X 2 3/8" X 4 1/8"

People who viewed this item also vieved

Primode Sponge Neoprene Roll, For Multi Purpose Use, 1/2" Thick X 14" Wide X 58"

Neoprene Rubber Strip 1/2" Thick x 3" Wide x 48" Long

High Temp FDA 3" wide White Silicone Rubber Sheet 1/8" Thick Temperature Strip

Neoprene Rubber self adhesive strip 1 1/2" wide x 1/16" thick x 33 feet long

UHMW white Plastic - 3 inch diameter x 2 3/4 inches long

Pipe fusion 4 jaws McElroy 4 in. DIPS x 2 in. IPS new

McElroy Pipe Fusion Machine Datalogger DL4501

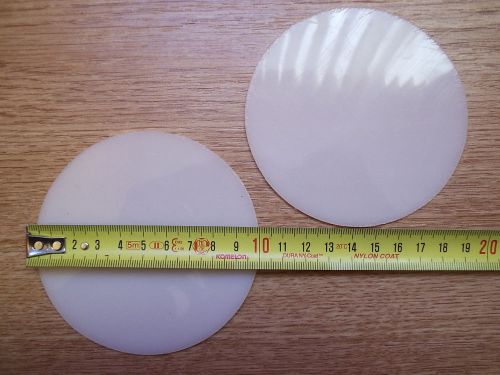

2 pcs. x Polyethylene PEHD DISC MATERIAL OD 100 mm x 2 mm THK Sheet white HDPE

Polycarbonate Clear Makrolon 4 BY 8 SHEET FIVE SHEETS

Gray Opaque Acrylic Plexiglass sheet 1/8" x 24" x 24" (#504)

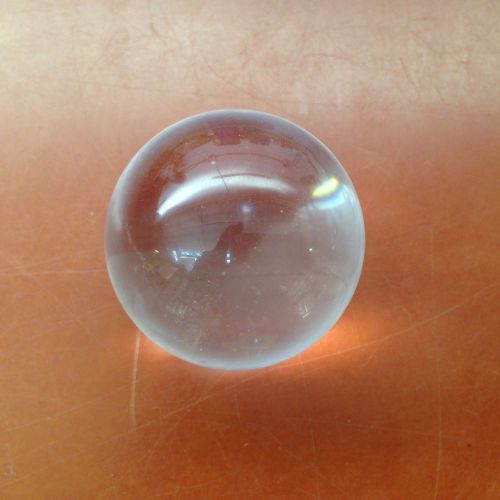

1/2" CRYSTAL CLEAR SOLID ACRYLIC SPHERES / ACRYLIC BALLS - 10 PC

12" clear Acrylic round tube 8-1/4" o.d., 8" i.d. 1/8" wall

Plastic polish Novus set of each 8 oz size

Cast Nylon 6 Plastic Sheet 3.25" x 12" x 24"

Cast Nylon 6 Plastic Sheet 3.25" x 12" x 12"

Nycast SLX Nylon Plastic Sheet 1" x 10.5" x 19.5" - Purple

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies