US $1,999.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Make | Eaton Compressor |

Directions

Similar products from Air Compressors

Champion VR7F-8 7.5 HP 80 Gallon Vertical Advantage Series Air Compressor

15 HP Screw Air Compressor CLEAVER BROOKS AQUA CHEM 230/460v

Black Cat 6-Gallon Portable Air Compressor

Gardner-Denver Electra-Saver II 50-Hp Air Compressor 125-PSIG 85351-Hours

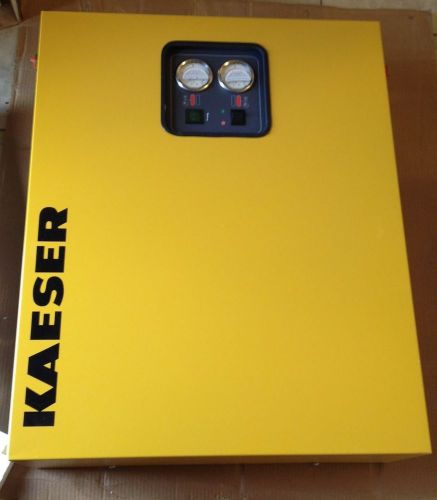

KAESER DRYER KADW-20 WALL MOUNTED DESICCANT DRYER Electric KADW-20-000

88 PUAS CompAir INDUSTRIAL AIR COMPRESSOR, Used No Reserve!

NEW US AIR SCREW COMPRESSOR WITH GARDNER DENVER PUMP AIR END AIREND 25 HP 25HP

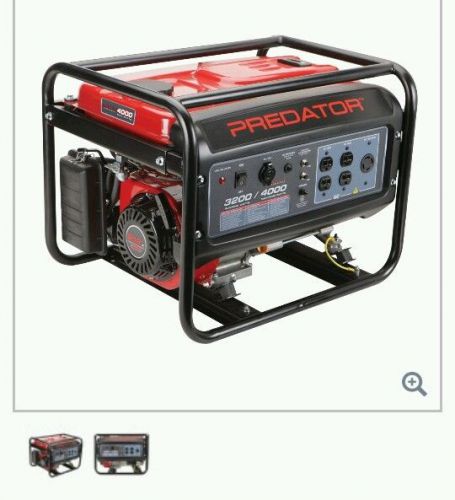

L@@K 4000 PEAK/3200 RUNNING WATTS 6.5 HP (212CC) GENERATOR EPA

Champion HGR7-3K 14Hp Kohler Two Stage Compressor 30 Gallon Electric Start

Ingersoll Rand Gas Air Compressor SS3-GH HONDA 5.5 HP 11.8 CFM 90 PSI

Quincy Northwest Posi-Drain Timer PD7000

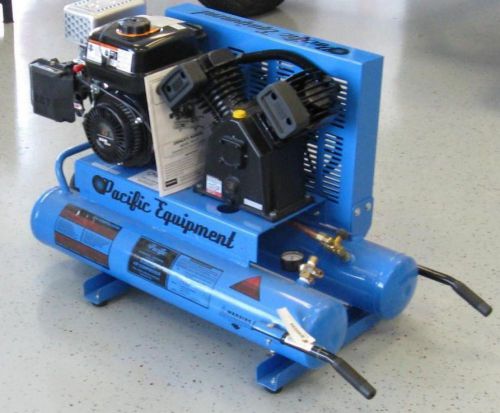

Pacific Equipment Industrial Air Compressor

(like Coltri) High Pressure Compressor Fire CNG Paintball Scuba 5000PSI

Eaton Compressor! 75HP 3 Phase Rotary Screw Compressor

MAGNETEK PNEUMOTIVE AIR COMPRESSOR PUMP LGH-406-X 60 PSI 980139

Eaton Compressor! 10HP Single Phase Rotary Screw Swing Arm Pkg

Brand New! Eaton Compressor! 30HP 3 Phase Rotary Screw Package

REGENERATIVE BLOWER 1.1 HP, 71 CFM,

REGENERATIVE BLOWER 3.4 HP, 185 CFM,

People who viewed this item also vieved

WERNERS S7702-1 SECTIONAL FOOT LADDER SHOE <271J2

Makita DC9700A Fast Battery Charger

Allpower 10,000W Portable Generator w Electric Start, APGG10000 High Performance

S34 NEW OEM KAWASAKI GENERATOR IGNITOR CDI MODULE 21119-2001 KG5000 BM3117

Curbing Business with Equipment and Trailer

FOLEY BELSAW MODEL 387 SHARPENER WITH STAND As Found in an Estate Ser # 28891

Bartell Reversible Diesel Engine Plate Trench Compactor

Mintcraft T1623L Plumbers Wrench, 1-3/4" - 2-1/4"

Kennedy Tool Box Machinists Steel Chest 7 Drawer

Akira Miki Power Grip Chisel Triangle 3.0MM From Japan

ONAN BTC AUTOMATIC TRANSFER SWITCH 600 AMP 277 480 BTC-4478781 W/ BYPASS

Kushlan Products Model 600 Wheelbarrow Concrete Mixer with New Universal Stand

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies