US $91

Directions

Similar products from Clips & Jaws

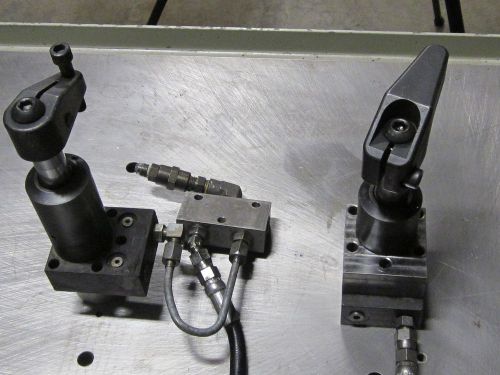

Clamps swing type hydraulic, spring loaded, set of 2 VEKTEK good contition

1 1/32" New H S Twist Drill With #3 MT Tapered Shank

1 1/8" New H S Twist Drill With #4 MT Tapered Shank

1 5/32" New H S Twist Drill With #4 MT Tapered Shank

Vintage L.S. Starrett No.196-G Or 645-G Flat Or Round Stock Clamp Hand Tool /Box

DE STA CO WELDING AIRCRAFT TOGGLE CLAMP PLIERS LARGE NICE COND MECHANIC TOOL

Odd lot of clamps, C clamps and others

FESTO STANDARD CYLINDER DNC-63-200-PPV-A

Carr Lane Roemheld 1911-702 712 R Swiftsure WorkHold

Vestil 1/2 ton plate clamp no. EPC-10

6 BASSICK KASPAR HOOK CLAMPS (aprox 3")

VEKTEK 70-5430-08 1912 J PRESSURE LIMITING VALVE

DE-STA-CO TYPE 807-UL Pneumatic Steel Hold Down Clamp VACUUM FORMING MACHINE

VEKTEK PART 91-6009-02, 91-5213-01, 91-6006-02, 91-5205-06, 91-5205-01, ETC...

VEKTEK DECOUPLER 56-0005-08 1509 L, 10-1016-01

VEKTEK DECOUPLER 56-0005-20 3110 A, 10-1016-01

VEKTEK DECOUPLER 56-0005-20 2310 A, 10-1016-01

Lot of Two Toggle Plier Clamp Machinist Tool Detroit Stamping

12" Billings #12 Heavy Duty Bridge C-Clamp Welding Tool, 40 Lbs, FREE SHIP 2 USA

New De-Sta-Co Horizontal Hold Down Clamp & Flanged Base Solid Bar, TC-215-S

People who viewed this item also vieved

Lathe or Mill Wedge Shape Machinist Block, 8 by 5.25" 1.25 by 13/16" thick

Starrett # 129 Bench Block machinist tool punch pin milling lathe metal vintage

CHUAN BRAND HARDENED STEEL PAIR OF V-BLOCKS 4.13" x 4.13" x 3.13"(105mm x 105mm)

Lathe Follower Rest Traveling Steady Rest Steadyrest 16" base

PRECISION CNC LONG NOSE POINTED LIVE REVOLVING CENTER MT 3 - NEW 3 MORSE TAPER

LIVE LATHE CENTER KNURLED BODY 3MT MORSE TAPER SHANK

Skinner Chuck 3412-M 3 Jaw 3” center 12” diameter

6.5" Hardinge Powerhold 3-Jaw Hydraulic chuck, Used

CHIN YU 8” Chuck B60 High Class Quality 4 Jaw 2” Center Threaded 4 Bolt NEW

Kennametal VDI-ER-1620 Collet Chuck

Komet UA3313141 ABS 40 ER25 Collet Chuck

Pratt Burnerd Lathe Collet Chuck Closer with Multisize Collet Set

1/8" ER16 Collet ER 16-0125 mfg.unknown

Erickson 33/64" TG100 Collet 100TG0516 04018CD5

Solid Angle 45° x 45° x 90° Plate.

Ground steel plate 7.25 wide x 20.5 long x .5 thick

SMW Systems Model 250T Long Run System Pallet Changer

Jergens 40301 Cast Iron Speed Handle 4-1/2" Arm Spread 3/8-16 x 1" Lot of 6

Jergens 39907 Blank Aluminum Speed Handle 8-3/4" Arm Spread Not Tapped Lot of 5

Jergens 39904 Blank Aluminum Speed Handle 6" Arm Spread Not Tapped Lot of 3

Dividing Plate for 6'' Horizontal/Vertical Precision Rotary Table, #5817-5006

8'' Horizontal/Vertical Precision Rotary Table, #5817-4008

12" High Performance Precision 4th & 5th Axis CNC Tilting Rotary Table USA Used

BROWN & SHARPE No. 1 Vise, Vintage Machinist Vise with speed handle knob, USA

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies