US $15.95

| Condition | Like New

:

A book that looks new but has been read. Cover has no visible wear, and the dust jacket (if applicable) is included for hard covers. No missing or damaged pages, no creases or tears, and no underlining/highlighting of text or writing in the margins. May be very minimal identifying marks on the inside cover. Very minimal wear and tear. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “This is a Mailed CD, Not a Book !!!” |

Directions

Similar products from How-To Guides & Manuals

Mycom Refrigeration Compressor Parts & Service Manual

ALLEN BRADLEY 1336 PLUS II ADJUSTABLE FREQUENCY AC DRIVE USERS MANUAL 1997

Century Precision Ball Bearing Equipped Honing Machine Operating Service Manual

MASSEY FERGUSON 165 SERVICE MANUAL Workshop Repair Guide Manual 4 IN 1 PDF CD

Davison's Textile Blue Book 2008 (ISBN 0875150942)

Personal Recollections of Trinity College North Carolina, 1887-1894 (Hardcover)

Whitaker's Reminiscences, Incidents and Anecdotes: Rev. R.H. Whitaker

The ancestry of Thomas Lovell and his wife Mary Ellen Ricker

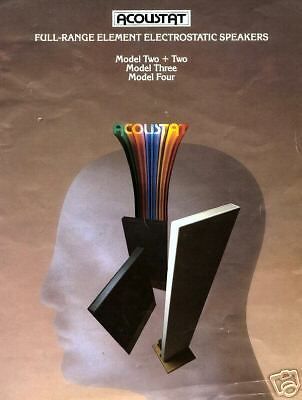

ACOUSTAT SERVICE MANUAL BROSURES ELECTROSTATIC SPEAKERS CD

CASE 580C CK LOADER BACKHOE TRACTOR SERVICE MANUAL WORSHOP REPAIR MANUAL CD

Haas Lathe Operators Manual *892

Fb1316 Blu Ifr/Vfr Pilot Kneeboard/Blue

DEUTZ BF4M2012 BF4M2012 C BF6M2012 C ENGINE SERVICE MANUAL WORKSHOP REPAIR

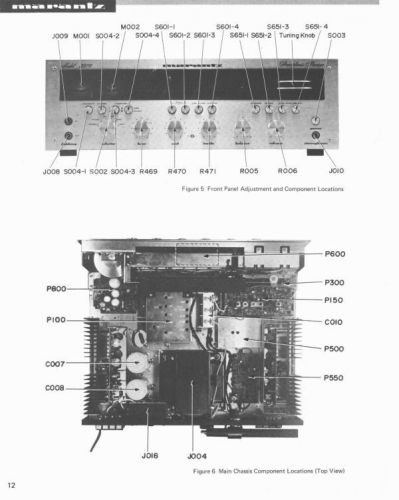

MARANTZ SERVICE MANUAL MANUALS AUDIO TECHNITION AMP AMPLIFIER REPAIR DVD

JOHNSON EVINRUDE 1.5HP to 40HP SERVICE MANUAL 1956 to 1970 OUTBOARD MOTOR BOAT

Detroit Diesel V-71 SERVICE WORKSHOP MANUAL ENGINE MOTOR OVERHAUL 1000 pgs

TRAILER BUILDING PLANS CAR FARM HORSE CAR HAULER cd

Espar Hydronic 10 & Hydronic M Water Coolant Heater Service & Parts Manual

DEUTZ 912 913 914 Service Manual Workshop Repair Manual Repair Cd

CASE 580 SUPER K LOADER BACKHOE CONSTRUCTION KING SERVICE MANUAL PDF CD

People who viewed this item also vieved

Wave Biotech 96 96B1-FMDU-DDBM Temperature Controller

Whirlpool Maytag Gas Range Cooktop Stove Spark Igniter Electrode Igniter 55"

Festo, MCH-3-1/8, LOT OF 2, NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies