US $40.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Model | NR-3094 R |

| MPN | NR-3094 R |

Directions

Similar products from Ceramic Inserts & Face Mills

9PCS NEW CNGA 432 AB30 CARBIDE INSERTS

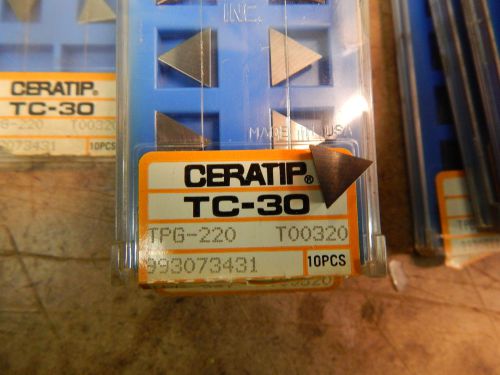

Ceratip TPG 220 TC-30 Ceramic Insert

Ceratip TPG 222 TC-30 Ceramic Insert

TAEGUTEC CNGA-434 CERAMIC INSERTS (10 PCS)

KENNAMETAL CERAMIC INSERTS CNG-454-T0820 (5 PCS)

SPC-632-T CERAMIC SILICONE NITRATE INSERTS (10 PCS)

Ceratip NDC 322 DR T00220 TC-50 Ceramic Insert

CBN (Cubic Boron Nitride) NR-3025R SPL/CLR Grooving Tool Insert .025 Radius NIB

CBN (Cubic Boron Nitride), SGN1 NR-3078 L Grooving Insert .078 Radius NIB

PCBN , SGN1 NG-3110 R, Grooving Insert, .110 wide, .035 Radius NIB

CBN (Cubic Boron Nitride), SGN1 NR-30375 R Grooving Insert .0375 Radius NIB

PCBN, SGN1 NG-3097 R Grooving Insert, .097 wide, .020 Radius NIB

PCBN, SGN1 NG-4250 R Grooving Insert, .250 wide, .0225 Radius NIB

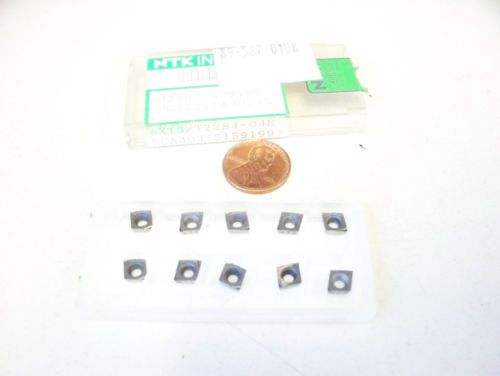

NTK ceramic metal cutting inserts CPGT 731 diamond 0.215 x 0.215 x 0.09 thick

100 PCS KENNAMETAL TNG 432T K060 CERAMIC INSERTS

1 NEW LAWSON STEEL GREASE FITTING 1/8 - 27 PTF 90 DEGREE ZP / DT 06203

5 NEW LAWSON STEEL GREASE FITTING 1/8 - 27 PTF 90 DEGREE ZP / DT 06203

new VALENITE SPG 434 T00820 Q6 CERAMIC INSERTS -box of 10

10 pcs Sandvik Coromant M30 Carbide Milling Inserts 009242N49 Grade 2040

![TUNGSTEN Ceramic Inserts RNGA-43 AB30 Qty 10 [003]](/_content/items/images/61/2490361/001.jpg)

TUNGSTEN Ceramic Inserts RNGA-43 AB30 Qty 10 [003]

People who viewed this item also vieved

4 CARBIDE BURS, 1/4" shank, (W13), used, USA., burrs, FREE SHIPPING

Everede CDCD-15-CV7 Carbide Inserts (10 New Inserts) (O 120)

SANDVIK CAPTO C4 TOOL HOLDER 431-360172L5-1 TAKES DNMG INSERTS

Lot 3 Design Rite XL 1/2" 4 FLUTE COATED CARBIDE END MILL New USA Sharp

New Super/Morse No.5733 - 15/16" Dia. Expansion Reamer HSS Carbide Tipped

Set of Ten Center Marking Punches

WHITNEY METAL TOOL CO No. 16 HEAVY DUTY PUNCH PRESS Fabrication 3/8 thru 1/4

BUNDLE OF 5 HSS BLADE 350 x 2.5 x 40 140 TEETH INDUSTRIAL COLD SAW BLADES 350MM

TWELVE !! Simonds 21" x 2" x 4 TPI HSS Power Hacksaw Blades Made In USA

Hougen Rotabroach Cutter 15/16x2 New

National Machine Tool No. 2-1/2 3/8" Keyway Cutter

ATLAS LOGAN CLAUSING CRAFTSMAN southbend collets 5c new 4pc.set

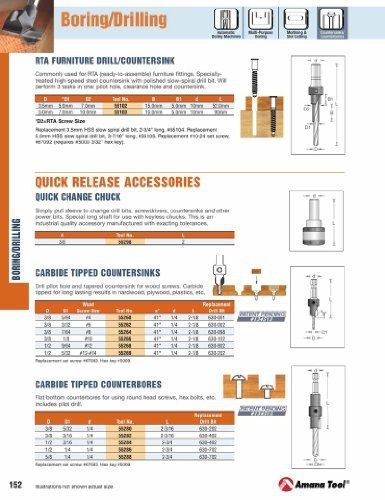

Amana 55268 QUICK COUNTERSINK 1/2" DIAM

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies