US $9400

| Condition: | New other (see details) | Product Type | Mining equipment |

| Custom Bundle | No | ||

| Non-Domestic Product | No | ||

| MPN | CCFB300 | ||

| Model | CVD-FB300 | ||

| Brand | Flexicone | ||

| Modified Item | No |

Directions

Similar products from Mining & Outdoor Equipment

2003 MCNEILUS 12.5 CY Concrete Portable Mixer Trailer Ready Mix # 3106

MSA CALIBRATION KIT NITROGEN CHECK GAS R22 FREON R22 (2 TANKS)

EVGA GeForce RTX 3060 XC GAMING 12G-P5-3657-KR 12GB GD HDMI DP PX1 Raven Coin

Universal Auto Car Steering Wheel Cover Anti-slip Bl*PX Leather Breathable

EVGA GeForce RTX 3080 FTW3 ULTRA 10GB GDDR6X Graphics Card HDMI DP ETH BTC RVN ~

MSA CALIBRATION KIT PORTA-GAS NITROGEN R-123 / MSA R-123 WITH HOSING AND VALVES

fill rite fuel transfer pump 12v 20gpm Fr4210D 1/4hp 19amps tuthill

Kennametal Roof Bolter Bits New!

Reelcraft CU8100LN Light Industrial Hand Crank Hose Reel 100' Air/Water Hose ...

2011 DRAGON 500 BBL Portable Frac Tank 21000 Gal # 3096

2010 DRAGON 500 BBL Portable Frac Tank 21000 Gal # 3091

2007 Salty’s 500 BBL Portable Frac Tank Open Top # 3038

SE Patented Stackable 13-1/4" Sifting Pan, Mesh Size 1/50" - GP2-150

Rust Proof Gold Pan Basin Nugget Mining Dredging Prospecting Sifting Panning

Milwaukee M18 Transfer Pump 2771-20 (Tool Only) (E10013475)

Air Compressor Electric DC 12V Hookah Diving Yacht Boat Hull Cleaning Dredging

Centrifugal gold concentrator mining CCFB300 with Vibrating screen classifier

Fiskars Aluminium Tools Gold Prospecting 25 Year Warranty Trowel Crevice Tool

11 Piece Offset Screwdriver Set Sluice Tool Gold Prospecting

People who viewed this item also vieved

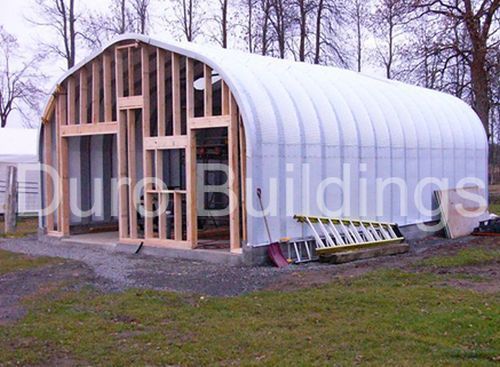

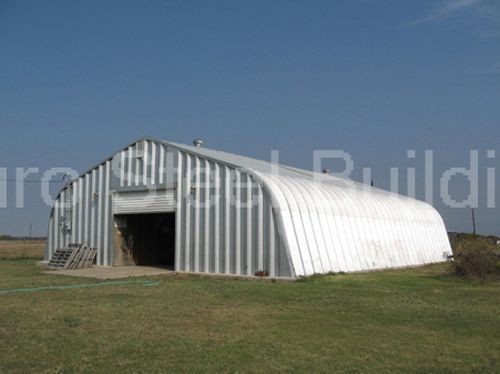

DuroSPAN Steel 40x90x16 Metal Building Kits Factory DiRECT Pole Barn Alternative

DuroSPAN Steel 25x27x16 Metal Building Kit Factory DiRECT Storage Barn Workshop

DuroSPAN Steel 40x95x18 Metal Buildings Factory DiRECT RV Tractor Trailer Shed

(4) Domestic Cold Water Pipe Labeling Stickers

(3) Plumbing Pipe Labeling Stickers Drain Condensate Return Lo-Pressure Steam

Fabtech Crushing Plant Jaw Screen Cedarapids Universal Crusher (Stock #1717)

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies