US $12,450.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | CIP CLEAN IN PLACE PROCESS |

| MPN | PROCESS EQUIPMENT STATION | ||

| Model | EQUIPMENT STATION CLEANING |

Directions

Similar products from Cleansing Utensils

1.4L Ultrasonic Jewellery Cleaner For Glasses Jewelry With Display 110V/220V

Digital VGT-2000 Ultrasonic Cleaner 600ml Jewelry Tattoo 0.6L Coin Machine

Portable Daily Care Mini Ultrasonic Contact Lenses Cleaner Machine 100-240V

Cole Parmer Polystat H6L Circulating Water Bath

Brinkmann Lauda RM6 Chiller, Parts only

Fisher Scientific B14 Heated Water Bath with Isotemp 2100 Circulating Pump

Branson 1210 Ultrasonic Cleaner

Crest Custom Tank 24"L x 15" W x 14 H and Generator CG-1000-2T 240V. Brand New

1.4L industrial Dental Jewelry Digital Ultrasonic Cleaner 110 220v CE-6200A LCD

DYNEX ULTRWASH PLUS MICROPLATE WASHER

SONICOR SC-101T/D Ultrasonic Cleaning Bath With Timer

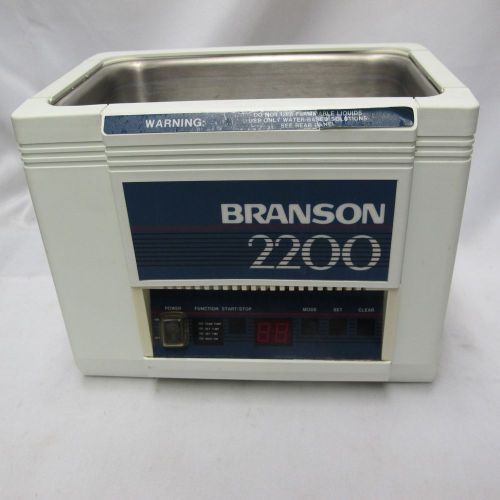

BRANSON 2200 BENCH TOP ULTRASONIC CLEANER 9-1/4" x 5-1/4" x 3-3/4" DEEP

GEMORO ULTRASPA COMBO 1 PINK TANK ULTRASONIC STEAM MACHINE 50 PSI New

AMSCO Reliance Sonic 550 Ultrasonic Cleaning Equipment Steris Free Shipping!

3574 Branson DHA-1000-R Ultrasonic Cleaner Bath

BlackHillsGoldSource Model 890 Professional Ultrasonic Cleaner - 30 Minute Timer

New 3L 120W Digital heated Ultrasonic Cleaner DHL/FEDEX/EMS Shipping

Sale 3L Heater Digital Ultrasonic Cleaner for Dental Lab Jewelry Tableware

New 5 Liter Digital HEATED ULTRASONIC CLEANER WASHER CLEANING Fast Ship From USA

Derui ultrasonic cleaner with mechanical ON/OFF DR-M07

People who viewed this item also vieved

Laser Photonics Analytic Division L5720

CMS OICO Minicams continuous air monitor CW agent detection

Leica HC PL FLUOTAR 5X Objective

^^ FISHER SCIENTIFIC CAT # 3-890 HEATER?

Vintage Jason Fine Quality Microscope

Manostat E-Series Economy Peristaltic Pump 72-410-014- show original title

Newport 481-A Series Rotation Stage

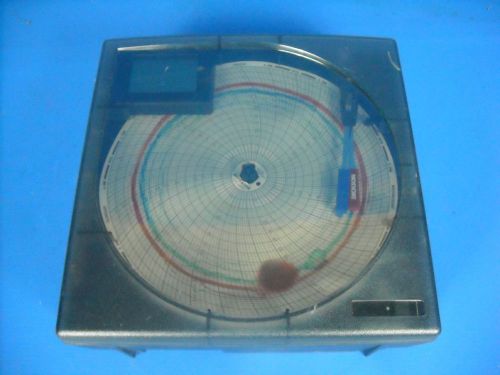

Dickson Model TH802 8" Digital Display Temperature Chart Recorder;Used;Untested

Laboratory mixer / Stirrer Lightnin L1U08

3M Attest 290 Auto-Reader - New In-Box

Cole Parmer Magnetic Spin-Master With Hot Plate 115V 60Hz 4Amps R77

24/40 Solvent Distillation Head 250mL w/ PTFE Stopcock Double Oblique

Yamato RE500 Rotary Evaporator

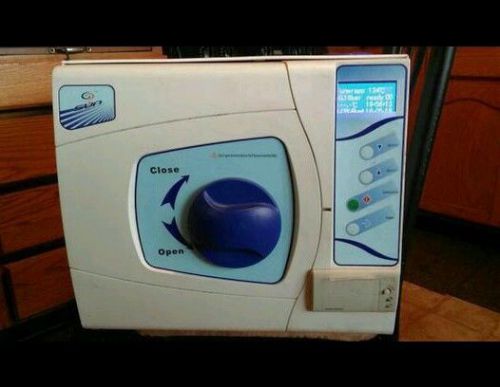

2014 Sun Series Sun23-11 LD Dental Digital Steam Autoclave Sterilizer w/ 3 Trays

Thermo Electron 57090ECA-115 EC570-90 mid-range power supply W/warranty

Boekel Scientific 260350 Rocker II Platform Chemistry Lab BIO

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies