US $1000

Directions

Similar products from Servo & Stepper Motors

ORIX MF930B-BC THERMALLY PROTECTED AC FAN

PANASONIC MSD023A1XXK AC SERVO DRIVER

Electric Machine Shaft 4mm DC12V 40-50MA 60RPM Geared Motor for Auto Shutter FKS

Electric Machine Shaft 5mm DC12V 40-50MA 50RPM Geared Motor for Auto Shutter FKS

Electric Machine Shaft High Torque 30RPM 12V Geared Motor for Auto Shutter FKS

Electric Machine Shaft High Torque 10RPM 12V Geared Motor for Auto Shutter FKS

VINTAGE Warner Electric SM-036-0030-AA Step Stepper Stepping Motor 2A

Parker Compumotor CM233FJ-01781 Rotary Servo Motor w/PEN060-025S7 Gearhead #2

Parker Compumotor CM233FJ-01781 340V Rotary Servo Motor w/PEN060-025 Gearhead

Electric Machine Shaft High Torque 120RPM 12V Geared Motor for Auto Shutter FKS

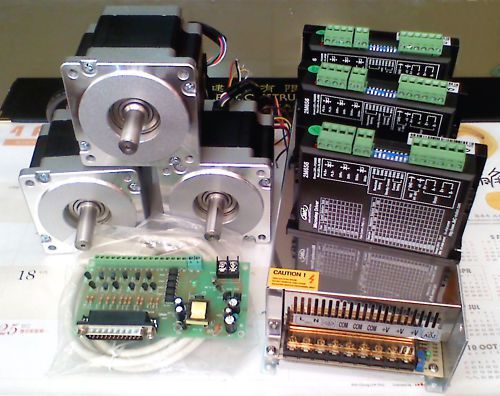

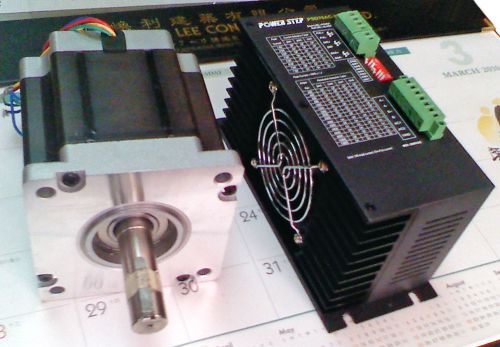

Cnc Milling Machine 3 axis NEMA34 PC Micro step motor Kit 637oz.in for Knee Mill

Cnc Milling Machine 4 axis Mach3 PC Control Kit NEMA23 step motor Stepper 16kg

Cnc Knee Mill 3 axis NEMA 42 step motor AC 80-220v Stepper Driver 12N.m KIT

Cnc Milling Machine Router 3 axis PC Stepper Control Kit NEMA23 step motor 22kg

Kollmorgen AKM24D-BNM2EF00 0.83kW 8000RPM 640VDC 3-PH PM Servo Motor +Gear Box

SIEMENS SINUMERIK MMC 103 200MHz 64MB 6FC5210-0DA21-2AA1

Siemens Sinumerik 802D 6FC5610-0BA10-0AA1 6FC56100BA100AA1

12V air pump 370 motor aquarium fish oxygen pump oxygen filling pump with holer

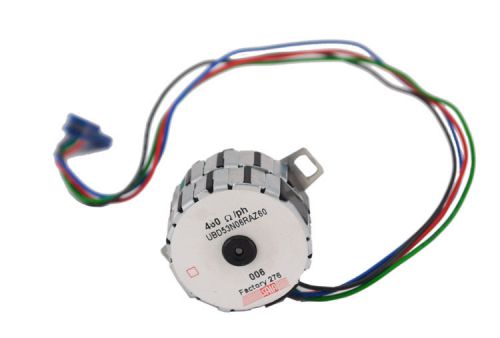

Saia UBD53N06RAZ60 Rotary Stepper Motor for Dionex AD25 Absorbance Detector O.B.

Parker Compumotor CM233FJ-01781 Rotary Servo Motor w/PEN060-025S7 Gearhead #1

People who viewed this item also vieved

NEW PARKER XR057 370FT AP23M A ROTARY ACTUATOR XR SERIE

HONEYWELL MP958A 1017 1 PNEUMATIC VALVE ACTUATOR

Thomson Industries SPB 10 OPN Super Pillow Block 5/8" Shaft

ROBOHAND RR-18-90 ROTARY ACTUATOR / 90 DEGREE TURNTABLE

Parker Daedal 3-Axis Positioner Linear Stage XYZ Positioning Travel 110mm & 35mm

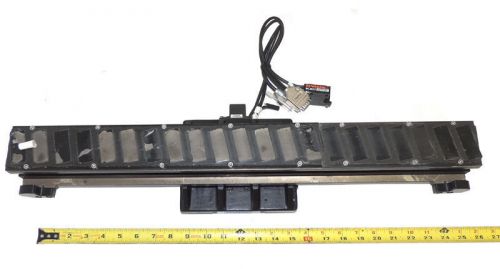

Parker 400LXR Ball Screw Linear Positioner Table 310mm Stage Travel 120mm Motor

Rockwell Anorad LCK-1 Linear Motor 25" Magnetic Track Rail & Renishaw Encoder

IKO Rail and Block LWA 15 R - 180mm Long (CNC)

Ballscrew 1610-400mm ( Diameter:16mm Pitch:10mm L400mm) end machined +ballnut

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies