US $28.00

Directions

Similar products from Acetyl & Delrin Materials

AFAB ENTERPRISES - Natural Virgin Acetyl, Curved Piece 12" x 12" x 1-1/2" thick

AFAB ENTERPRISES - Natural Virgin Acetyl, 16" OD x 11 1/4" ID x 3/4" "Donut"

3 NATURAL ESD ACETAL PLATES; .25" X 10" X 10"

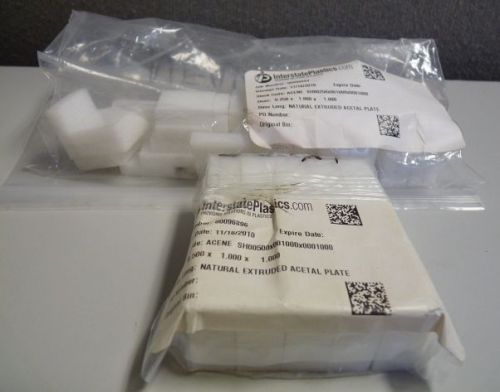

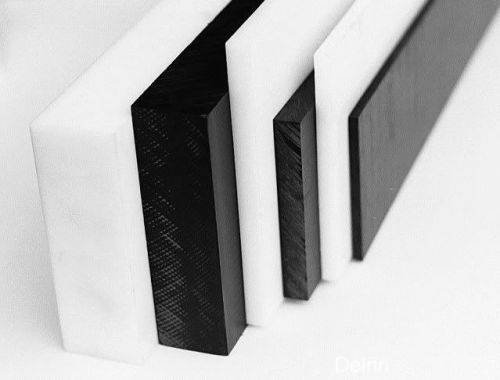

NATURAL EXTRUDED WHITE ACETAL PLATES - 15 / .5 X 1 X 1, 37 / .25 X 1 X 1

AFAB ENTERPRISES - Natural Virgin Acetyl, Rect. Bar 3-1/2" x 3-5/8" x 13-1/4"

AFAB ENTERPRISES - Natural Virgin Acetyl, Irregular 12" x 12-1/2" x 3-1/2"

(008) Delrin Rod - 7 pc bundle - 2"OD x 5"L - Free Shipping

Acetal / Delrin engineered plastic...1" x 12" x 7" white/natural #1

Acetal / Delrin engineered plastic...1" x 12" x 7" white/natural #2

Acetron Acetal 4.5" 4-1/2" Dia x 13" Long Rod Bar Disc 8869 GP POM 114mm

Copolymer Acetal Rod, 3" diameter x 7" long

NEW AIR POWER CG 176-519 CG176519

(011) Delrin Rod - 6 pc bundle - 5"L - 1 1/4" OD to 1 5/8"OD

Nylon Plastic-Bushing-Spacer-Roller-Sleeve 1/2" Wide X 5/8"Long X 9/64 ID 12-Pak

Delrin Virgin white sheet 3'' x 4.625'' x 7'' Made in USA CNC (5.2E)

Delrin virgin black rod 3'' dia x 1'' Made in USA CNC (0.3AK)

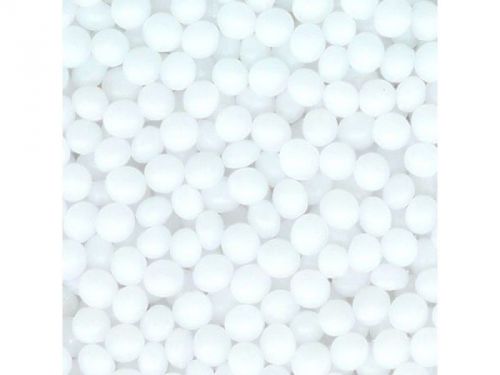

Acetal 10 Lbs pounds Lupital F20-03 POM Copolymer Plastic Pellets Natural Resin

Delrin 3" diameter rod copolymer , 12" natural color & CONDUCTIVE Plastic !

CNC Mill material Plastic White Delrin/poly acetal 200x200x60mm

Delrin Virgin white sheet 2.375'' x 3'' x 3'' Made in USA CNC (1.1X)

People who viewed this item also vieved

SILICON RUBBER SHEET HIGH TEMP RED/ORANGE COMMERCIAL GRADE 1/8" 36" x 36"

SILICON RUBBER SHEET HIGH TEMP RED/ORANGE COMMERCIAL GRADE 1/4" 36" x 36"

SILICON RUBBER SHEET HIGH TEMP SOLID RED/ORANGE COMMERCIAL GRADE 8"x8"x1/4"

SILICON RUBBER SHEET HIGH TEMP SOLID RED/ORANGE COMMERCIAL GRADE 12"x12"x1/4"

HDPE Bar Strips White .031" x 2.0" x 25 Ft Roll

HDPE Bar Strips White .063" x 1.0" x 25 Ft Roll

HDPE Bar Strips White .050" x 4.0" x 10 Ft Roll

HDPE Bar Strips White .125" x 2.0" x 10 Ft Roll

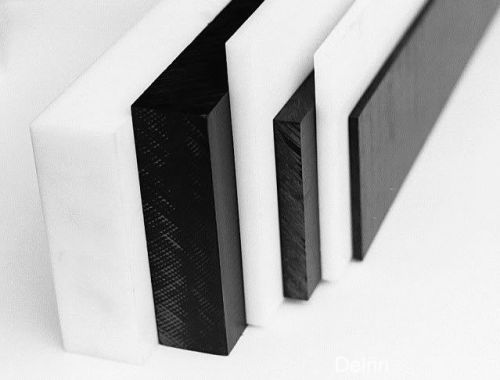

Lexan sheet Colored Black 1/4" x 36.375" x 16"

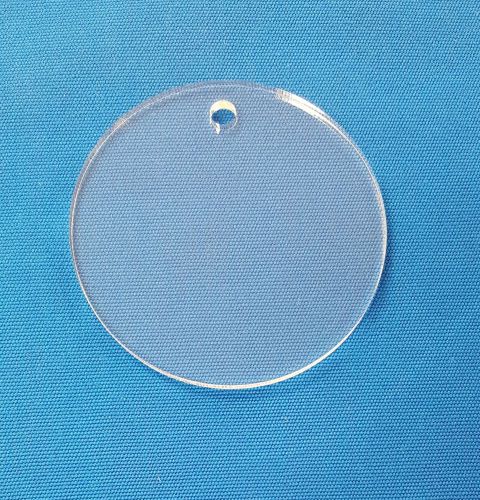

50 ACRYLIC KEYCHAINS 2"D CLEAR CIRCLE BLANK DISCS 1/16" THICK PLASTIC PLEXIGLASS

GREEN ACRYLIC PLEXIGLAS SHEET COLOR #2030 3/16" x 46.75" x 7.875"

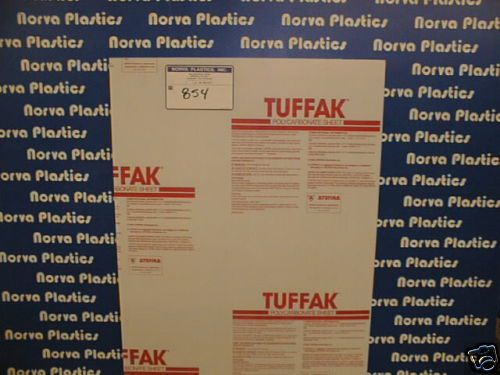

(854)POLYCARBONATE CLEAR 1/4" THICK 24" X 48"

PHENOLIC ROD 4" DIAMETER X 29" LENGTH STK 5488

Virgin Teflon (PTFE) 1.625" 1 5/8" x 1ft 12" ROD BAR US SELLER! Free SHIPPING!

1.5" Diameter by 16 3/4" Inch White Natural Color Nylon Plastic Rod Roundstock

3/8" Bearing ID x 1-9/16" OD X 1/2" WIDE POLYURETHANE 95 A Black covered bearing

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies