US $3200

Directions

Similar products from Other Pump Machinery and Parts

Fuju VKP041P Single Phase Coolant Pump

SANDPIPER 2" DIAPHRAGM PUMP ALUMINUM #5231257J P/N HDF2-DV6A WET:476.248.363

SANDPIPER 2" DIAPHRAGM PUMP ALUMINUM #523117J P/N:HDF2.DV6A SN:2186411 USED

SANDPIPER 2" DIAPHRAGM PUMP ALUMIN. #523109J P/N:HDF2.DV6A SN:4008658 USED

PLASTIC DIAPHRAGM PUMP 1/2" #5241038J NO TAG USED

PLASTIC DIAPHRAGM PUMP 1/2" #5241031J NO TAG USED

JOHN S. BARNES HYDRAULIC PUMP #523341J MOD:G20D-2C13B1-A1A61L MILD RUST NEW

Stenner QPA102-1 Innermost Quick Pro Pump Head 26-100 psi

FINISH THOMPSON 1 X2X(8) IRON PUMP W/ TOSHIBA 10HP MOTR #5231234J USED

BARNES SUBMERSIBLE PUMP 2" #524954J MOD:EH1092L RPM:3450 PH:3 USED

Stenner QP400-1 QuickPro Tube Housing with Latches

Stenner QP400-2 QuickPro Tube Housing with Latches 2-PK

Stenner QP401-2 QuickPro Latches 2-PK

Stenner QP100-1 QuickPro Tube Housing Cover with Bushing

Stenner QP100-4 QuickPro Tube Housing Cover with Bushing 4-PK

Stenner QP251K Pump Head Service Kit 0-25 psi

Stenner QP252K Pump Head Service Kit 0-25 psi

Stenner QP253K Pump Head Service Kit 0-25 psi

People who viewed this item also vieved

US ELECTRICAL MOTORS BM92 NEW AMT PUMP 424098

Alling-Lander 5HP 1750 RPM Motor

MITSUBISHI DC SERVO MOTOR TYPE HD MODEL NUMBER 81-125

Graymills Superflo Pump, BSW308H-1/3F, Leeson Motor, Used, WARRANTY

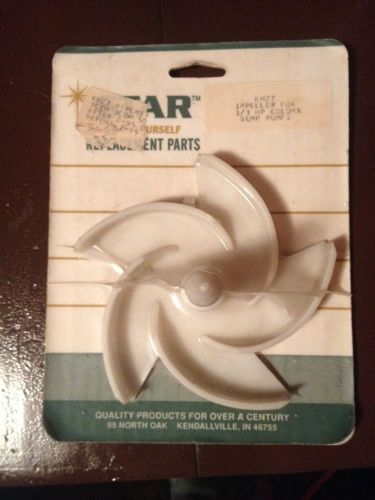

Star REPLACEMENT SUMP PUMP KH27 IMPELLER #441856

Franklin Electric Pump Controll with QD

Basement Watchdog Special Battery Backup Sump Pump USED BWSP

HONDA SUBMERSIBLE PUMP WSP100AA NEW

GOULDS 5SV9FF4F10 3 HP STG ESV SS VERTICAL INLINE WATER PUMP GRUNDFOS CR5 CR 5

GOULDS 3SV11TF4F20 3 HP STG ESV SS VERTICAL INLINE WATER PUMP GRUNDFOS CR3 CR 3

GOULDS 3SV11FF4F10 3 HP STG ESV SS VERTICAL INLINE WATER PUMP GRUNDFOS CR3 CR 3

GOULDS 1SV4TA30 4 STG ESV STAINLESS VERTICAL WATER PUMP LIQUID END GRUNDFOS CR1

Cessna/Eaton 25580 rag triple gear pump NOS

Nachi VDR-1B-1A3--B-1478G hydraulic vane pump

Hydraulic pump Sauer Danfoss tandem

3 boxes used Filpro carbon vanes KRX(S)-5 UPC 04009565010-4 blades per box...mz

Gast 0523-101Q-G314DX Vacuum Pump And Emerson Motor SA55JXGTB-4696

Pfeiffer Pfeiffer Vacuum w/ Sensor PTR26504

Cal Weld 10-142269-00N 3-Way Flex Bellows Vacuum Splitter DN 160 101081 Used

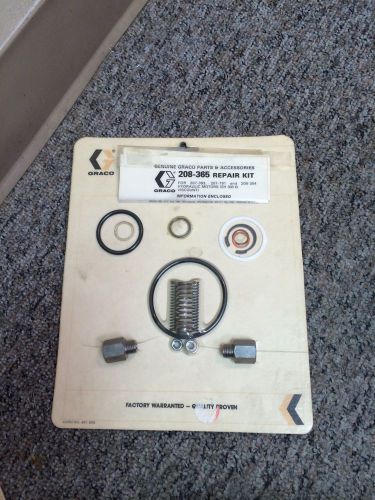

Graco Hydraulic Motor EH 333/Viscount Repair Kit 208-365

Alliance Hose 3" Water Discharge Hose 50 ft.

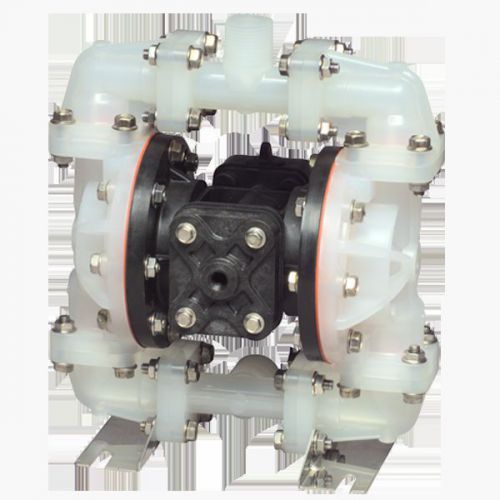

Sandpiper S05B2PUTPNS000 Non-Metallic, Double Diaphragm Pump, Air Operated

Ingersoll Rand 54672654 Filter

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies