US $55.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Diversitech |

| MPN | iqp-120 | ||

| Model | iqp-120 |

Directions

Similar products from Pumping Machinery & Parts

HONEYWELL THERMOSTATIC MIXING VALVE AM101-1, 3/4" NPT

SAUERMANN Si-30 MINI CONDENSATE REMOVAL PUMP 230VOLT 50/60 Hz

Single Stage Rotary Vane Vacuum Pump, 1/4HP 3CFM

Kotec Pressure Boost Pump DX-8000-0350 Used #68991

SUNTEC OIL BURNER PUMP 2 GPH 3450 RPM A2VA-7116 A2VA7116

Armstrong Pump Impeller 816302-317

Bell & Gossett Series 100 Booster Pump Iron Body 106189 UPC 683328061894

SAUERMANN 230V 50/60HZ Mini Condensate Removal Pump SI3100MIUS23 S13100

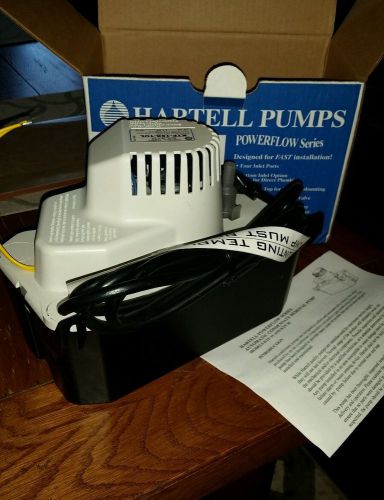

BNIB Hartell KT-15X-1UL Condensate Pump Powerflow Series

Sauermann si-30 230volt condensate removal pump

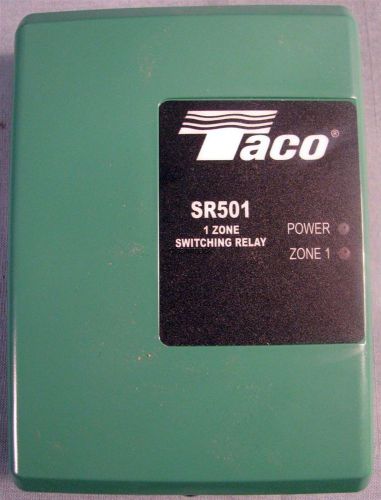

TACO SR501 PUMP 1 ZONE SWITCHING RELAY WITH PRIORITY

Taco 006 Plumb n' Plug Pump w/ Line Cord and Analog Timer NOS

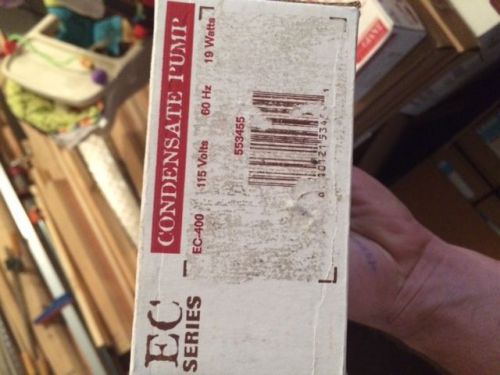

Little Giant EC-400 Condensate Pump

TACO WATER CIRCULATOR PUMP 111-B8 110-041 BRONZE 1/8 HP 1725 RPM 1 1/4 NPT NEW

USED AURORA PENTAIR 15 HP CENTRIFUGAL PUMP 342A BF 6x6x9,

People who viewed this item also vieved

Totaline P270-2000I duct smoke detector and sample tube. New

Scott Fetzer Brushless Blower BBA14-211HMB-00 240V 5.25A 50/60 Hz free ship

FUJI ELECTRIC RING COMPRESSOR VFC400A-7W *EXCELLENT CONDITION*

FUJI ELECTRIC RING COMPRESSOR VFC104P-5T, 115V 1PH *EXCELLENT WORKING CONDITION*

SQUARE D RELAY UNITS ( 2-AR.65 ) MOTOR STARTER OVERLOAD HEATER

SQUARE D RELAY UNITS ( AR23 ) OVERLOAD THERMAL UNIT HEATING ELEMENT

J/W Johnson Wilson 1600W 460V Heater 20Z200Z1524F

Emerson Motor KA55HXSMW-2346 1/3 HP 115V 1075 RPM 1PH New

Carrier #320725-756 Draft Inducer Motor Assembly

Fasco D1101 Evaporator Coil & Refrigeration OEM Replacement Motor

0.25 Outside Diameter copper tubing Remnant; at least 40 feet or longer

EMERSON THERMAL EXPANSION VALVE BAEB-2-HCA NEW

Beckett 51580U primary and ignitor assembly original factory part

JB Refrigerant Locking Cap SHLD-4 Universal With Locking Bit

LOT OF 2 NIB Parker 082S Liquid Line Filter Dryer 1/4" Sweat

Danfoss BD50F Direct Current Compressor R134a12-24V DC 100-24V AC 50/60Hz USED

PRECON ST-O3 Outdoor Air Thermistor Temperature Sensor -30F to 140F

GENERAL SIGNAL TRANSFORMER PART # 2821390T00 NEW " OLD STOCK "

Goodman/Amana 20165703S 20165703 201657-03S 20165702 Furnace Ignitor - New OEM

PSG Freedom Advantage Programmable Thermostat

TP9600A1007 Pneumatic Direct Acting Thermostat New In Box

HONEYWELL SUPER TRADELINE HEAVY DUTY HEATING / COOLING THERMOSTAT T6051A 1016

HONEYWELL MAGNETIC LP GAS VALVE 3/4 -- 8 oz. -- 24 V -- .75 AMP -- FREE SHIPPING

MCDONNELL & MILLER FLOW SWITCH -- 1/2 -- ITT -- FREE SHIPPING

NIB SIEMENS SSB81U Electronic Valve Actuator With Floating Control Signal

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies