US $1,600.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

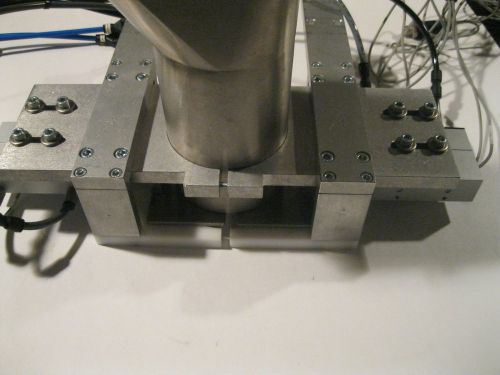

Brand | ITW |

| Model | N52P121-C24HBB |

Directions

Similar products from Other Machinery for Packaging & Labeling

NEW VIDEOJET 353088 MAXUM SPARE PART KIT FOR PRINTER B271150

NEW VIDEOJET 353088 MAXUM SPARE PART KIT FOR PRINTER B271172

NEW NORDSON 1029796 HOT GLUE GUN VALVE MODULE D413760

STAINLESS STEEL SLIDE GATE, DUAL CYLINDERS, PNEUMATIC CONTROL W/ REED SWITCHES

AUTOMATIC TOP LOAD MAB CASE PACKER MODEL B88 FOR BOTTLE APPLICATION

VideoJet I-Pro XHS Small Character CIJ Ink Jet Printer Machine No 24V DC Valves

BRAND NEW VIDEOJET 1620 1510 STAINLESS STEEL PRINTHEAD COVER

NEW VIDEOJET 204446 PRESSURE SENSOR SWITCH D366096

NEW VIDEOJET 204446 PSF100A PRESSURE SENSOR SWITCH D366101

METTLER TOLEDO HI SPEED CHECK WEIGHER DUAL LANE UNUSED STAINLESS STEEL

NEW NORDSON 131475B SENSOR 10-30V-DC D414106

NEW MARKEM 0828288 PRINT HEAD MOUNT D271669

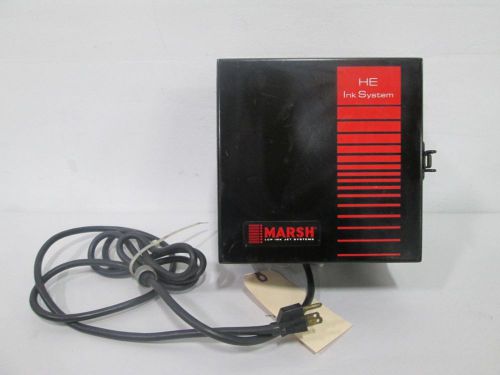

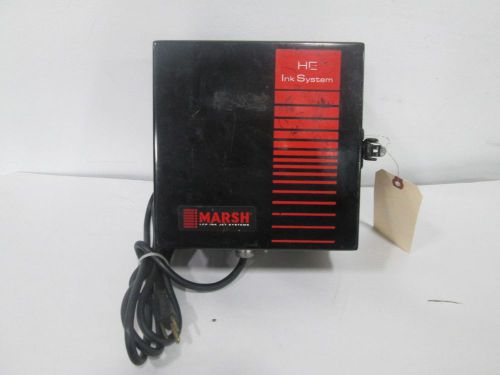

MARSH HE INK JET SYSTEM LCP 115V-AC 1A AIR PNEUMATIC CONTROLLER D293091

MARSH HE INK JET SYSTEM LCP 115V-AC 1A AIR PNEUMATIC CONTROLLER D293092

MARSH HE INK JET SYSTEM LCP 115V-AC 1A AIR PNEUMATIC CONTROLLER D293094

NEW VIDEOJET 16028 LOW INK CABLE ALARM ASSEMBLY D430184

The Fitzpatrick Co. Fitzmill Comminutor Model DAS06

Capping Machine Pneumatic 21842

ACCU-SORT AXIOM 400 HIGH SPEED BAR CODE SCANNER

NEW NORDSON 938152C HEATER CARTRIDGE ELEMENT 240V-AC D384935

People who viewed this item also vieved

2007 Poly Pack SS Pick and Place Tube Shrink Wrap System

Conflex CW160 automatic HFFS wrapper

Benison LE-200 Shrink Sleeve & Cap Applicator

DOBOY OPERATOR INTERFACES 03601-54-080

NEW! ITW Diagraph IJ384 5760019384S2 Impulse Jet Print Head New In Box!

Labelette 11C - Hot glue label machine

Videojet Mother Board SP356400-02 NEW

Trine Change Parts Set - 1 Liter - Brand New

Quadrel Q-65, Label & Hanger Tab Applicator

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies