US $110

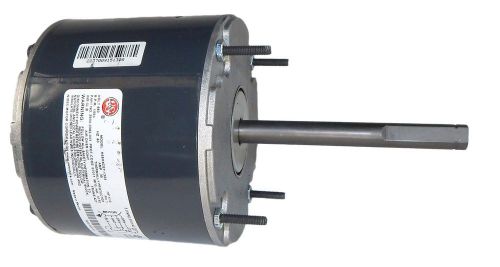

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Item is sold As Is, Untested.” |

Directions

Similar products from Engines

NEW GE General Electric 5KSM81HFL30077 unit bearing motor 230 volt 1550 rpm

GE ECM X13 5SME39HXL090 1/2HP 1050RPM Amana 0131M00053 Blower Motor - 1 YR WARR

A.O. Smith F48L35A50 Furnace Blower Motor 1/2HP 115V 1075RPM 3SPD 7.0A

Marley/Qmark Heater Motor 1/10 hp, 1550 RPM 480V # 3900-0362-001

OP17D740 MALLORY MOTOR RUN CAPACITOR 17.5/7.5 MFD 440V

GE Motors 5KCP39LGP918AS Blower Motor 1/2HP 115V 1075RPM 4SPD 7.90A

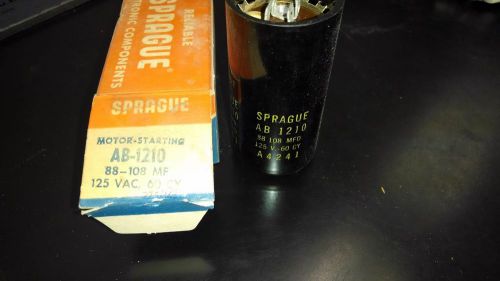

SPRAGUE AB-1210 MOTOR START CAPACITOR 88-108 MFD 125V

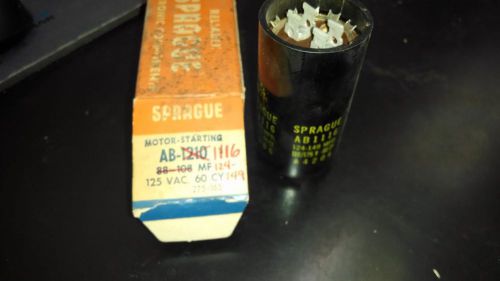

SPRAGUE AB-1116 MOTOR START CAPACITOR 124-149 MFD 125V

7195-0023 Fasco 3.3" General Purpose Motor 120 Volt 60hz type u95-air drive fan

Universal Electric Motor HE3G071N

GE 5KCP39PG N655 S 1/2 HP 1075 RPM 115v Single Phase Stock No. 3587 60Hz Motor

Fasco D1092 5.0-Inch OEM Direct

Broan Fan Motor (99080178, DA3E278) 1/12 hp 1050 RPM 115V Century Motor # 9649

Dayton 3M730D Shaded Pole Motor 3000RPM 1/40HP 115V 60HZ 1PH 1/4"x2" Shaft

NORDIC AIR MILITARY AC 3 TON 36000 BTU R-22 R-407C MOTOR CONTROLLER ECU B0014

Nutone Fan Motor (C34417, C-34417, 34417000) 3000 RPM, 120 Volts # 34417

FASCO D503 HVAC Motor, 1/10 HP, 1590 rpm, 230V, 3.3

NEW Dayton 4M222D Direct Drive 1/11HP 1550RPM 115V 3.0A Fan Blower HVAC Motor

GE Motors 5KCP39fgS848S Furnace Blower Motor 1/4HP 1050RPM 1PH 60Hz 2.60A

AO SMITH FDL1056 1/2 HP, RPM 1075. Model F48SP6L11B1, 115 Volts, 5.6 Amps, Rev.

People who viewed this item also vieved

Tsuge / Okuma Cabinet Heat Exchanger, E7391-090-485-1, USED, WARRANTY

Devilbiss Heat Exchanger Type MH Series 4015-1

Devilbiss Heat Exchanger 1/4" Port Type MH Series 501-1

Lennox Pulse Air Diaphragm 64L81

Lennox Pulse Air Diaphragm 64L80

BRAND NEW TACO SR501-4 SWITCHING RELAY 1 Zone

Groundfos 59896155 P1 Type UP 15-42 F 115V Cast Iron Circulating Pump

Brand New Taco 111-8 Cast Iron Three-Piece Circulator Pump - 1/8 HP

Overstock Semi Hermetic Copeland Refrigeration Compressor LACA-032E-TAC-800

Alco 401RD-3F35, 4 Way Reversing Solenoid Valve M.O.P.D. 400, D68517-1

true cooler compressor, tecumseh, 1/5 HP, R134a/R12, AEA3425YXA, 115 VAC

Honeywell Series 7774 Insertion Removal Device Stainless Steel New

White-Rodgers 36E36-304 Electronic Ignition Gas Valve

ESP UHS24 24V Universal Humidifier Solenoid

GENERAL GP8 GAS POWERED BLOWER VENTILATOR W/ HONDA 4.0 ENGINE, and BLOWER HOSE!

Fasco Inducer 7021-8428 P/N 21D330673

Fasco Inducer 7021-8693 P/N 1006168P

HONEYWELL R8225A 1017 FURNACE FAN RELAY *NOS*

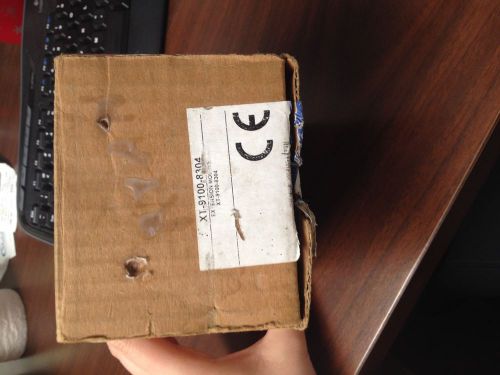

JOHNSON CONTROLS METASYS EXPANSION MODULE MODEL XT9100-8304

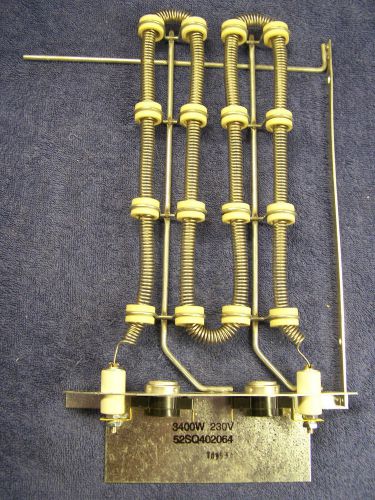

Carrier OEM 52SQ402064 Electric heater assembly 3400W 230V

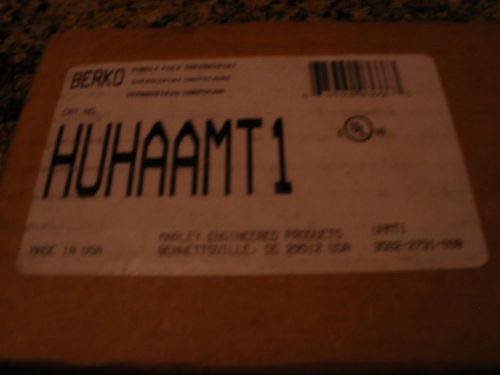

HUHAAMT1 BERKO SINGLE POLE THERMOSTAT FOR HUHAA SERIES HEATERS

New Braeburn 5020 Premiere Series 5/2 Day Programmable Thermostat

RANDELL PART #HDCNT200 REFRIGERATION THERMOSTAT

Duct Temperature Probe Dwyer TE-DFN-B0448-00

Modularm 75 Temperature Alarm ~ believe to be unsused REDUCED PRICE - AGAIN

New Honeywell L4064 B 2228 Combination Fan and Limit Control 5"

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies