US $87.11

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | MAX EPOXY SYSTEM |

| Country/Region of Manufacture | United States | ||

| Model | MAX BOND LOW VISCOSITY A/B |

Directions

Similar products from Caulk & Sealants

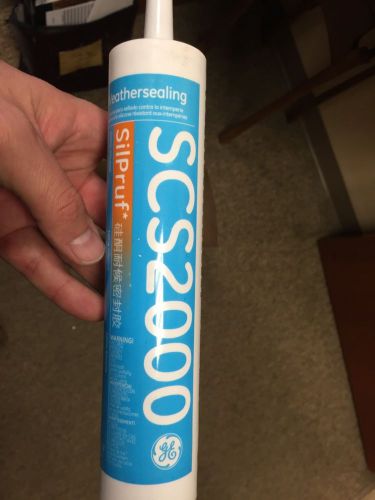

GE SCS2000 black silicone Lot of 12 - 10.1 oz tubes

CLEAR CASTING DECORATIVE EPOXY RESIN - GALLON KIT

Brillianize Plastic Cleaner - 8oz. w/ Free Microfiber Cloth

Green Glue Soundproofing Damping Compound - Case of 12 Tubes

*NEW* 13.5 OZ DUAL CARTRIDGE ROPPE STAIR TREAD EPOXY CAULKING COMPOUND ROP-ECCC

Hilti Hybrid adhesive HFX 9.3oz/275ml

3M Hi-Strength Spray Adhesive 90 - FAST SHIPPING!!

Homax Gloss Wet Look Cure Seal - 3 Pack

Specseal Fire Caulk- 16 (ES) & 10(LC)

Alex Plus Clear Window And Door Caulk

HDIP INC Endurable Sealer Concrete Sealer, Matte Finish - Free Shipping!

Epocast 1652 A/B Epoxy Syntactics

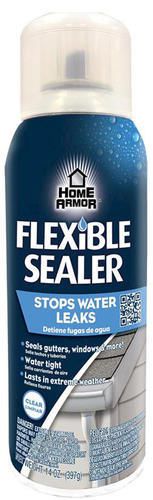

NEW - (2) CANS HOME ARMOR FLEXIBLE SPRAY SEALER 14 OZ each - CLEAR STOPS LEAKS

SIMPSON EDT22S 22oz EPOXY DISPENSING TOOL (AA3060-1)

American Sealants CLEAR SILICONIZED ACRYLIC LATEX CAULK Paintable 10.2 Fl Oz

Tremco Mono 555 Acrylic Terpolymer Sealant Gray Stone 300 mL Caulk

3M 6997-1 MANUAL DISPENSER CAULKING EPOXY GUN 22 oz used NICE!

People who viewed this item also vieved

45W R20 SW FLD REFL BULB 14878

Lot of 97 Simpson Strong-Tie Hurricane TIES Right anchor hanger #H5 R (E-4)

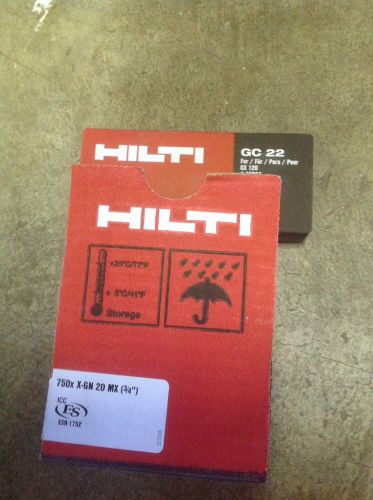

Hilti 3/4pins for GX-120 gun and fuel cell

Kim Lighting Lens ASSEMBLY LA6

New HEVI LITE WM-5-WT Wall Mount Round Cover Plate Lights Lighting 4.50" Dia

6" SQ SPLT ALUM CAP/BASE SQSTD06WHTS

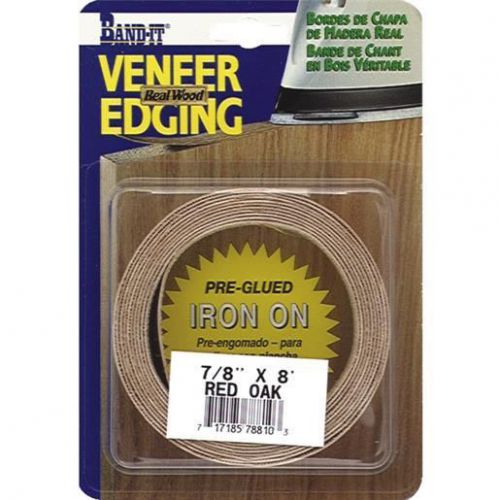

3/4X8 R OAK VENER EDGING 34810

Brembana, Thibaut, Loffler ISO40 Nicolai Tooling Cones for Granite Counter Tops

4 Inch Copper metal bonded Polishing 23 pad FREE SHIP UK Canada Europe Australia

Sidewall/Ceiling Register/Diffuser 8x4 One-Way White Tru Aire

LOMANCO ROOF TURBINE, WHIRLYBIRD, 12", Brown, w/adjustable base, Ball Bearings

Comm. Enclosed Trailer with Garnite Roofing System/Foam Insulation Spray Rig

Utilifoam QS-1 Foam Sealant Kit

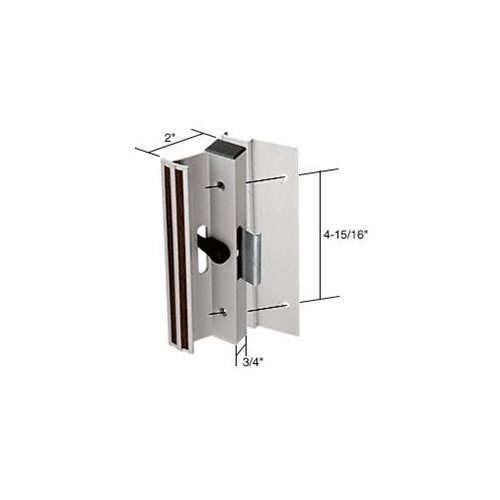

CRL Aluminum Clamp - Style Surface Mount Handle 4-15/16" Screw Holes for Lupton

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies