US $340

Directions

Similar products from Welding Rods & Wires Sets

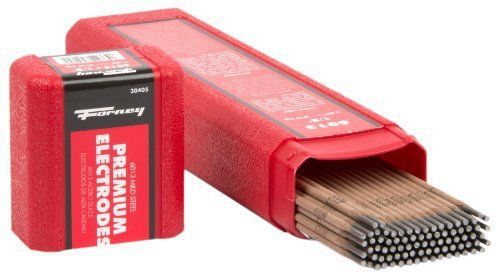

Forney 30405 E6013 Welding Rod, 1/8-Inch, 5-Pound

Er316l X 1/16" X 36" X 10# Box Stainless Steel Tig Welding Rod Blue Demon 10lbs

E71t-11 X .045 X 25# Spool Gasless Flux Core Welding Wire Blue Demon

Lincoln Electric MIG Welding Wire, 5356, .035, Spool

SPECIAL METALS N625-035-30SS02 - 20 LBS - WELDING WIRE, WEIGHT: 20 LBS, #225746

SPECIAL METALS N625-035-30SS02 - 21 LBS - WELDING WIRE, FILLER METAL, NE #225745

SPECIAL METALS N625-035-30SS02 - 19 LBS - WELDING WIRE, FILLER METAL, NE #225735

KISWEL K-71TLF FLUX CORED ARC WELDING WIRE 0.045" (1.14MM) 33LBS

Blue Demon Aluminum Welding Wire

welding rods , brazing rods , sil;fos 15 ,soldering rods

AlcoTec 518320047 20lbs. Almigweld Aluminum MIG Welding Wire

LINCOLN NR211MP INNERSHIELD FLUX CORE .035 X 1# SPL

Flux core E71T-1 size .035" Mig Welding Wire 33 pound spools

Lincoln electric 5/64 innersheild E71T-11DC 14lb welding wire spool

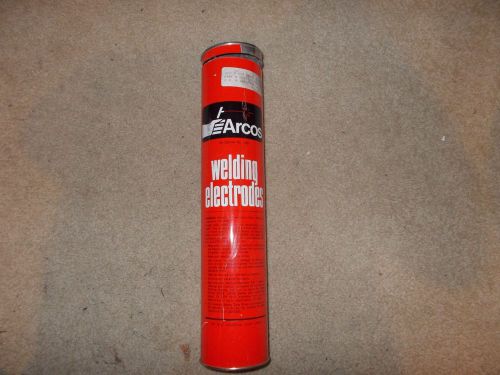

Arcos E316L-16 Stainless Steel 3/16 STICK ELECTRODE WELDING ROD 10 lb can

New Hobart Stick Aluminum Electrodes Rods DC 1/8IN X 14IN Welding Welder 10 Set

Forney 42286 Mig Wire, Mild Steel ER70S-6, 0.30*Diameter, 10-Pound Spool

Blue Demon 7024 X 3/32" X 14" X 5# Plastic High Speed Carbon Steel Electrode

0.035 in. 10 lb. Spool Flux-Cored Nr211 Mild Steel Welding Wire tool cable rope

People who viewed this item also vieved

Century/ Solar Mig Welder Power Switch 216-042-666 Part

Cable Adapter 195378 for Miller TIG Welding Torch 9/17 Series (U.S. Seller)

Miller 248282 M-100 Welding Gun 10Ft .030-.035 Wire

Bessey MGC-1 250AMP Magnetic Ground Clamp -55 Lbs. Pull

MILLER M25 169599 15FT .030-.035

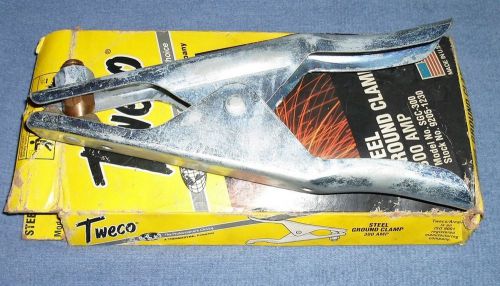

Tweco SGC-300 Steel Ground Clamp 300 amp (New in Box)

WELDPORN premium MIG/STICK Long Cuff Welding Gloves

K&K Welding Liner assy 15 foot B44215 FREE SHIPPING

ESAB 999473 3/4" Copper Nozzle 10pcs

24FN-37-S TWECO style 3/8" Copper Nozzle 2pcs

24FN-62-S TWECO style 5/8" Copper Nozzle 10pcs

BERNARD B1501 BE1501 3/4" Copper Nozzle 10pcs

5x Bulk Lot - Bernard MIG Welding Wire Weld Contact Tips 7488 030 0.030

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies