US $59.99

| “Left over from job in October. Controlled Climate Fresh.” |

| Brand | Pro Guard Coatings |

| MPN | F1501/2 |

| Model | F1501 |

| Country of Manufacture | United States |

Directions

Similar products from Caulk & Sealants

Hybrid Resin System 1/2gal E84 Rated w/Carbon Nano Tech Free Priority Shipping

TileLab Grout & Tile Sealer 1 Gallon

(10) 28oz LOCTITE PL PREMIUM POLYURETHANE CONSTRUCTON ADHESIVE 28 Ounce

Pro-Seal E-Z Fuse Silicone Tape 15413

Surface Guard Granite Marble Slate Stone 20 year Sealer 32oz x 2 bottles

Simpson Set XP 22 Seismec anchoring adhesive

Fasson Foil Tape UL181A-P/181B-FX 2.5"x60yds Air Duct HVAC silver 0800

LORD 406/19 GB Gray Acrylic Adhesive ONLY 375ml (12.7 FL.OZ.)

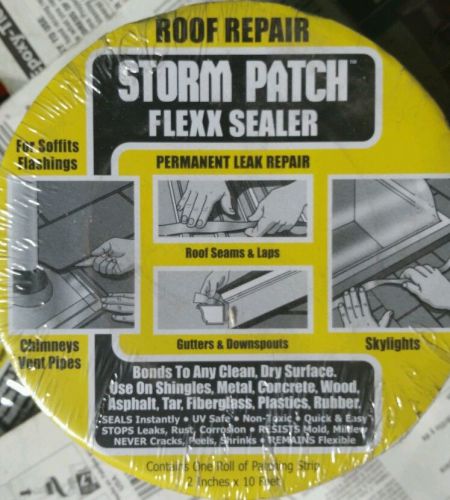

KST Storm Patch Flexx Seal Permanent Leak Repair-Bonds To Any Clean Dry Surface

4 cans BORING SMITH PANEL HOLD GUN FOAM ADHESIVE QUANTITY OF 4 - 24 OZ. CANS

GE SCS1000 Series Contractors 100% Silicone caulking - 6 Tubes White

1 gallon DYKEM STAINING FLUID PURPLE NEW OLD STOCK

Caulking, Dispensing, Applicator Gun Uppar 2500G for Hilti RE-500 Cartirdges

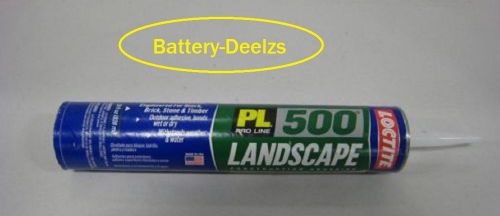

LOCTITE PL500 LANDSCAPE BLOCK ADHESIVE (Lot of 3) new

Hardcast Carlisle High Velocity Duct Sealant DS 321 Caulking Tube 1/12 Gallon

(4) Almond Tremco TremGlaze SA1100 Paintable Siliconized Acrylic Sealant Caulk

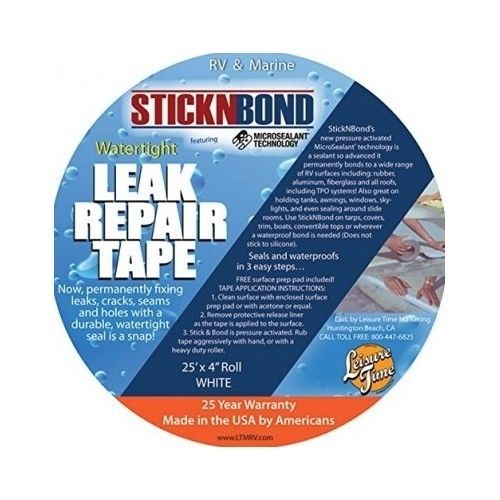

White Roof Seal Leak Repair Tape StickNBond 4" x 25' Roll Grabs All Surfaces

People who viewed this item also vieved

Gits 1633-050801 Style 1633 Breather Vent, 1/2-14 NPT Breather with Screen and

Imperial Manufacturing PA-4W 4-Inch Premium Intake Cap White

COPPER GROUNDING SPLIT BOLT USED WITH GROUND BLOCK CONNECTOR ROD WIRE CLAMP

T&B 2" STRAIGHT BULLET NON-METALLIC CONDUIT FITTINGS.

12-24 FLAT HEAD BOLTS SCREWS SELF DRILLING 2-3/16 OVERALL LENGTH (QTY 51) #4298A

Simpson Strong-Tie HRS12 Strap Tie-12" HEAVY DUTY STRAP

Cooper Lighting Ld6 Ld610D010 Portfolio Led

NEW LUTRON FS-5E FAN SPEED DIAL 1P ROTARY CONTROLLER 120V-AC 5A FANDIAL B236577

DELMHORST NAVIGATOR PRO MOISTURE MAPPING METER KIT GREAT SHAPE!!!

400 hardboard panels 18" x 96"

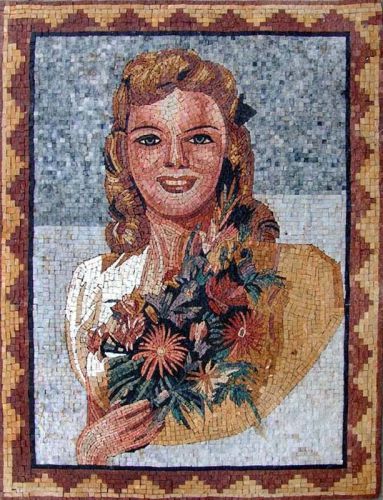

Lady and Flowers Marble Mosaic Mural Hand made

NEW LOVEJOY JAW COUPLING HUB L090 HUB 7/8 LOT OF 2

Roof Cement and Patching Sealant

RF250PLUS BASIC KIT RENOVA SYSTEM FOR ROLLER SHUTTERS dumpster size max L=250CM

RF200PLUS BASIC KIT RENOVA SYSTEM FOR ROLLER SHUTTERS dumpster size max L=200CM

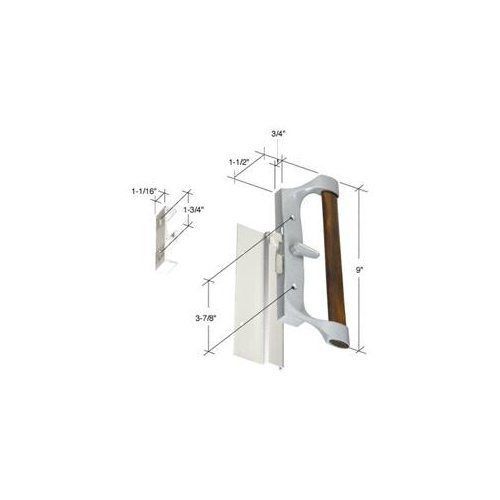

CRL White Low Profile Hook-Style Surface Mount Handle 4-15/16" Screw Holes

CRL Aluminum/Wood Hook-Style Surface Mount Handle with 3-7/8" Screw Hole Centers

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies