US $180

Directions

Similar products from Carbide Inserts & Face Mills

Sandvik #SNV-03510-L TNMG 436MR 4015 Carbide Turning Inserts

6-wnmg 432-pm ic4325 & 1 wnmg 432-TF ic9250

Huge Lot 140 pcs Carboloy RNMG 32E RPC 32H Carbide Inserts Grades 370, 350, 883

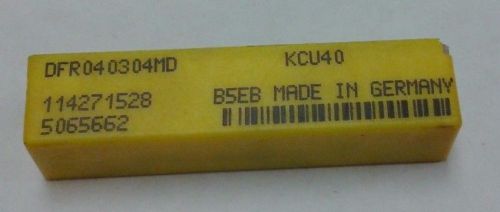

10x Kennametal Carbide Inserts DFR040304MD KCU40

10x Kennametal Carbide Inserts DFR040304MD KCU25

* 50pcs * FREE SHIPPING * SANDVIK 345R-1305M-PM 4240 50pcs

SandVik N151.2-800-60-4P 235 Grooving CARBIDE inserts box of 10 inserts

3M AXKT 1304PDR-MM IC950 ISCAR *** 10 INSERTS *** FACTORY PACK ***

Iscar Cut Off Carbide Inserts GFF 3L IC-20 QUANTITY 13

Iscar Cut Grip Carbide Inserts GIMF 608IC-428 QUANTITY 23

INTERSTATE CARBIDE TURNING INSERTS ICR-39700-L U3585 RPG-32 I22 LOT OF 4 BOXES

Iscar Cut Off Carbide Inserts GFF 6N IC656 QUANTITY 21

Kennametal SM454 DW1006569R00 K9 Carbide Inserts

Iscar Milling Carbide Inserts MM GRIT 18K3 .17-0.20 528 QUANTITY 5

CNMG 432-PM 12 04 08-PM 4215 SANDVIK CARBIDE INSERT

SANDVIK N123H2-0500-0004-GF 1125 10PCS

Iscar Cut Off Carbide Inserts GFF 4N IC656 QUANTITY 8

Iscar Cut Carbide Inserts GF N5J IC20 QUANTITY 5

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type D & E, 2 1/4" x 5", Uncollared, Used

Keyway Broach Bushing Guide, Type D, 2 1/16" x 5", Uncollared, Used

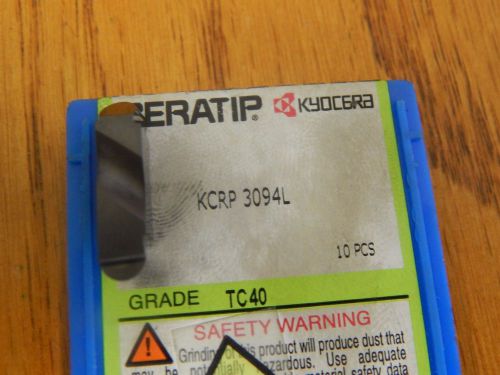

Kyocera Ceratip KCRP 3094L TC-40 Ceramic Insert .187" Wide

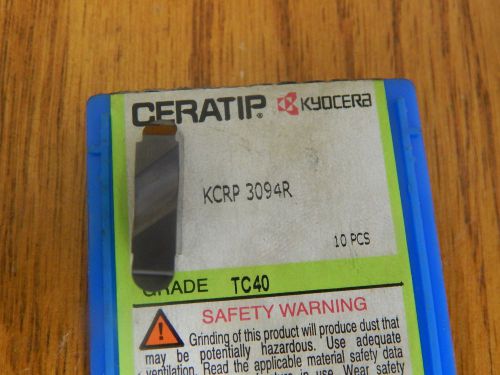

Kyocera Ceratip KCRP 3094R TC-40 Ceramic Insert .187" Wide

Nachi 7/8 x 7/8 x 5 1/2 oal two flute double end end mill "BRAND NEW"

LOT OF 12 SINGLE AND DOUBLE ENDED END MILLS 5/8" TO 1-1/4" WELDON

NEW CASE OF 6O PC'S DROP FORGED AVIATION LEFT CUT RED HANDLE TIN SNIP $210. NR

NEW DROP FORGED STEEL LEFT CUT RED HANDLE METAL / TIN SNIPS $3.50 NR

DAYTON DIE BUTTON KHX 87 150 M2 P .3710 LOT OF 3 #3178A

Die shoe for hydraulic/mechanical press . price included dies ( 2202-638 )

Straight Flute Shell Reamer 2-3/16" "Tianjin"

Twist Flute Shell Reamer 2-1/4"

Lot 1pcs HSS Hole Saw Dia 48mm High Speed Steel Hole Tool

Lot 1pcs HSS Hole Saw Dia 20mm High Speed Steel Hole Tool

24 Vtg Used Machinist Gunsmith Punches Center Drive Pin Toolmaker GENERAL MFG Co

Used Carboloy Toolholder MCKNR-24-6E EXCELLENT TO MINT CONDITION

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies