US $220

Directions

Similar products from Carbide Inserts & Face Mills

KENNAMETAL 20pcs.of IH00063D IC7215 ,,,NEW INSERTS

New Sandvik Carbide Insert- CCMT 09T308-PR CCMT 3(2.5)2-PR 4215

Kennametal I 69 004 375 KC850 Carbide Inserts (QTY of 7) (R 48)

Iscar 16mm Carbide Head Insert Multi Master Mill MM FF160R2.0-L20-2T10 IC908

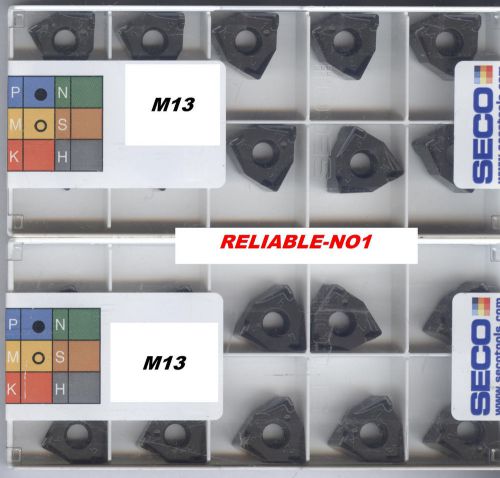

* 30pcs * SECO XNEX 080608TR-M13 MP2500 30pcs

SECO SNGN090312SLF CBN10 SNGN 323SLF CUTTING TURNING INSERT TOOL BRIDGEPORT BIT

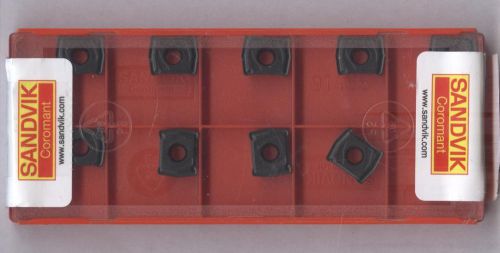

* 20pcs * FREE SHIPPING * SANDVIK N123J2-0500-0004-CR 4225 20pcs

10pcs.NEW SANDVIK LCMX 040304R-WM 3040, DRILLING

Lot of 89 Carbide Turning Inserts - TPG-321/322/327; TNG-322; TPU-322

ISCAR DGR 3102C-6D IC908 CARBIDE INSERTS 10pcs.

ISCAR SUMOCHAM IC908 CARBIDE DRILL TIP INSERTS 18.5mm *UESD*

Vardex Carbide Threading Inserts 3IR AG60, 8-48 TPI

SUMITOMO WDXT073506-G New Carbide Inserts Grade ACP300 8pcs L

SUMITOMO WDXT094008-G New Carbide Inserts Grade ACP300 10pcs L

SUMITOMO WDXT125012-G New Carbide Inserts Grade ACP300 6pcs L

(10) SECO Duratomic #SEMX1204AFTN-ME12 MP2500 Carbide Inserts

* 20pcs * FREE SHIPPING SANDVIK 266RG-16MM01A100M 1135 20pcs

NEW 20pcs.SANDVIK SNMM 433-PR 4235 or 120412-PR TURNING

People who viewed this item also vieved

duMONT 3/8-C HS KEYWAY PUSH THRU BROACH MACHINE SHOP TOOL MACHINIST 22208

Greenleaf CNGA-433 T1 WG-300 Ceramic Insert

CNGA 434T0420 KY1540 KENNAMETAL CERAMIC INSERT

Micro Miniature End Mill Woodson Tool 2 Flute .028 NOS

5x Robb Jack Solid Carbide 3/4"x3/4"x3/4"x5-1/4" 2 Flute Center Cutting End Mill

Standard Tool Co. HS Milling Cutter 4-5/8" x 1/16" x 1"

HS Milling Cutter 4-3/4" x 3/8" x 1-1/4"

LOT OF 14 VARIOUS DIES * 12 STANDARD AND 2 METRIC * W/ 4 HANDLES & 2 TAPS 1/2-13

Vintage Steel Number Stamp Punch Set in Wood Block Approx. 1/4" High

Vintage Morse 1 3/16" hand reamer in good usable condition

NATIONAL DETROIT MACHINIST TOOL HSVM NO. 9 ARBOR WITH Reamer UNUSED NR

MACHINIST TOOLS LATHE MILL Large Lot of Machinist saw Blades for slitting

10 Lot 1 Inch 25MM Diamond Coated Rotary Cut-Off Wheel Disc Blades W/ 2 Mandrel

Weldon DB-26 Deburring Countersink

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies