US $35,000.00

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “We did not test the equipment. We sell the system at AS IS condition without warranty and refund.Inspection is available against appointment by sales@quicksemi.com” |

Directions

Similar products from Other Semiconductors Production Tools

ASPECT RF ETCH CHAMBER FOR TOOL

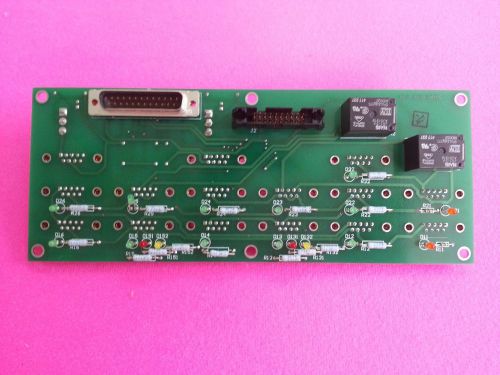

AMAT 0100-09104 PCB ASSY CONTACTOR INTERLOCK, USED

AMAT 0100-70028 ASSY, ROBOT INTERCONNECT PCB, USED

GENUS 34523-00,34524-00 DC POWER SUPPLY, LYNX3 , USED

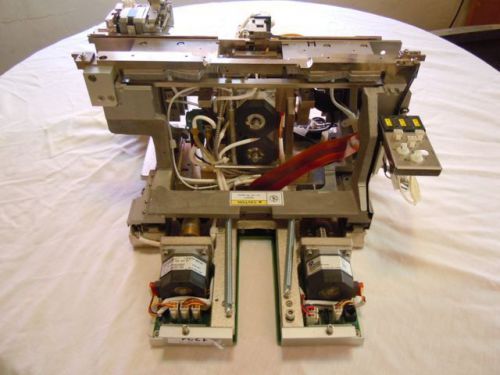

Kulicke & Soffa 8060 wedge bonder assembly

Lam Research Rainbow 4420 Plasma etcher RIE Semiconductor process equipment

HP4062UX DC Parametric Tester - 2848J00509

HP4062UX DC Parametric Test System - 2848J00634

Gasonics AE 2001 Plasma Etcher Semiconductor Process Equipment

NEW Genuine Kawasaki 0190-19496 Extension Hard Stop Kit 50953-1167 OEM SEALED

Gasonics L3510 Plasma Asher Semiconductor Process Equipment

NEW Adtec AX-2000III 2000W 13.56MHz Air Cooled RF Plasma Generator 4U HN-Type 3?

Plasma Therm 700 Series Wafer Batch Plasma Etcher Deposition

Refurbished Branson L3200 Plasma Asher Descum

Refurbished Tegal 901e Tegal 903e Plasma Etcher

Refurbished Branson IPC 2000 3000 4000 Plasma Asher Etcher Descum

Peak Vacuum Rapid Thermal Process System ALP-5000

Two Used Matrix 10 Plasma Asher Machine for 8 inch Wafer Process

People who viewed this item also vieved

Lot of 6 Signatone S-825 X Y Z Micropositioner 3 w/ Magnetic Base

Unitek Unipulse Miyachi X16/230 Welding Transformer 9-004-01 - 230V 50-60 Hz

Cascade Microtech SP-140-A-GSG-100HC + 140-GSG-100 (x2)

Credence 3520 Mixed Signal Tester Test System

S&A 5910/20 System Interface(M)

GO REGULATOR SPR Series Sub atmospheric Pressure Regulator

Binocular Stereo ZOOM Microscope 5X-80X w Boom Stand Long wk Distance Large FOV

* Lot of 13* Kulicke & Soffa 414FA-0213-R35 Bonding Capalaries

APPLIED TEST SYSTEMS PNEUMATIC ACTUATED #2605 CREEP TESTER- TENSILE (#1315)

![[LOT 17]12" 300mm Silicon Wafer Colorful Gradient w/ KTB-3002B Box #91](/_content/items/images/61/4471761/001.jpg)

[LOT 17]12" 300mm Silicon Wafer Colorful Gradient w/ KTB-3002B Box #91

![[LOT 25] 150mm ~6" Silicon Wafer for Art Projects *burned/discolored* *F4](/_content/items/images/62/4471762/001.jpg)

[LOT 25] 150mm ~6" Silicon Wafer for Art Projects *burned/discolored* *F4

ASQ 4” Quartz Boat for 6" Diffusion Tube: 9 Wide Slots, 2.5" High Legs ~NEW~

Solid State Equipment Corp. Model 200 - Wafer Cleaner and Computer

Pfieffer THM 1000 Turbo Pump Parts Only non Working

KARL SUSS MA 6" MASK ALIGNER (Refurbished with warranty)

PLASMA-THERM 700 RIE SYSTEM Reactive Ion Etcher

LOT OF 25 3 1/4" WACKER-CHEMITRONIC SILICON WAFERS 1 SIDE POLISHED 1 SIDE BLANK

TREBOR CHEMICAL PUMP MAGNUM 960

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies